Hello from Austin, Texas! I'm joining the forum after years of following this jewel of a website for smoking tips and techniques. What helped kickstart joining was my new endeavor that is building a smoker for my backyard, IN my backyard!

My old offset barrel char-griller that served me many great years fell victim to rust a few months ago so I'm replacing it with what I hope is a forever smoker. I helped my buddy build a rather large reverse flow cabinet smoker last year so I'm using what we learned from that build to make a scaled down version of his"Large Marge" in my backyard.

I'm using is a $100 cheapo gasless mig welder from Amazon that plugs into a regular ol house electrical socket.

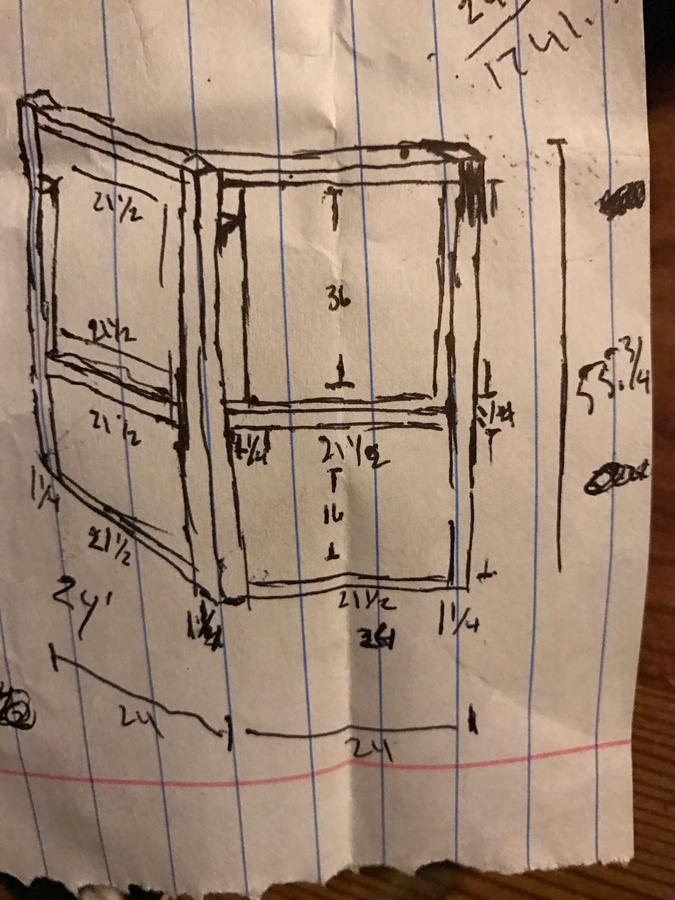

Here are my scribbles of the dimensions of what I'm building. The firebox is 1/3 of the cook chamber. In my book the only way to smoke is to use wood oak, pecan, or mesquite, all of which are available a plenty around here. The outside dimensions of the entire smoker will be 24" x 24" x 55 3/4"

There will be 2 false walls, one on each side that stop 3 inches from the roof of the cook chamber.

I'm currently working on the frame. Will post pictures as soon as it's done!

Thanks to all!

My old offset barrel char-griller that served me many great years fell victim to rust a few months ago so I'm replacing it with what I hope is a forever smoker. I helped my buddy build a rather large reverse flow cabinet smoker last year so I'm using what we learned from that build to make a scaled down version of his"Large Marge" in my backyard.

I'm using is a $100 cheapo gasless mig welder from Amazon that plugs into a regular ol house electrical socket.

Here are my scribbles of the dimensions of what I'm building. The firebox is 1/3 of the cook chamber. In my book the only way to smoke is to use wood oak, pecan, or mesquite, all of which are available a plenty around here. The outside dimensions of the entire smoker will be 24" x 24" x 55 3/4"

There will be 2 false walls, one on each side that stop 3 inches from the roof of the cook chamber.

I'm currently working on the frame. Will post pictures as soon as it's done!

Thanks to all!