- Apr 17, 2017

- 22

- 13

Hello everyone!

I would like to build 500 gallon smoker (Ordered 0.26x100x42-inch tube).

I want to have stable temperatures across the smoker. Not sure if I can handle same temperatures across 100-inch normal offset smoker. (But I saw video of Moberg Smokers and that was pretty accurrate!). Normal/Reverse? Would like to do one type of meat (pulled pork with ribs or alone briskets).

But I have few questions regarding the build.

I used calculator: Link to BBQ Pit Calculator

Firebox:

35x35x35 (102%)

Chimney:

Round 8x42

But I have few questions:

Green question mark: As per calculator, this should be 343 in^2. That is pretty clear, but.. How should I cut it? Leave some space from top (as heat shield). Or it should be in same level as top of firebox.

Orange question mark: I guess this should be exactly same as firebox > cooking chamber hole (343 in^2). Right?

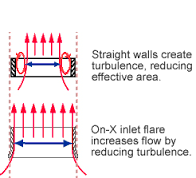

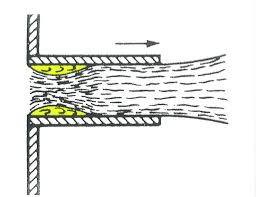

Brown question mark: I will have cylinder shape, so there is no "tank round shape" to help the airflow. Do you you any bent plate to have "fake tank round" shape?

Red question mark: Hole for chimney will be round 8-inch as rest of chimney. Right? Do you count chimney lenght from hole or from top of smoker?

Thanks a lot!

I would like to build 500 gallon smoker (Ordered 0.26x100x42-inch tube).

I want to have stable temperatures across the smoker. Not sure if I can handle same temperatures across 100-inch normal offset smoker. (But I saw video of Moberg Smokers and that was pretty accurrate!). Normal/Reverse? Would like to do one type of meat (pulled pork with ribs or alone briskets).

But I have few questions regarding the build.

I used calculator: Link to BBQ Pit Calculator

Firebox:

35x35x35 (102%)

Chimney:

Round 8x42

But I have few questions:

Green question mark: As per calculator, this should be 343 in^2. That is pretty clear, but.. How should I cut it? Leave some space from top (as heat shield). Or it should be in same level as top of firebox.

Orange question mark: I guess this should be exactly same as firebox > cooking chamber hole (343 in^2). Right?

Brown question mark: I will have cylinder shape, so there is no "tank round shape" to help the airflow. Do you you any bent plate to have "fake tank round" shape?

Red question mark: Hole for chimney will be round 8-inch as rest of chimney. Right? Do you count chimney lenght from hole or from top of smoker?

Thanks a lot!

Last edited: