I don't print decorative items, but only do functional parts, so if SLA isn't as strong, then I wouldn't be inetested.SLA and FDM printing are wildly different. Parts on an SLA machine can end up with completely smooth surfaces and virtually no visible layer lines because they can get down to insanely high resolution. The issue with SLA is that the parts are usually pretty brittle, and the resin is expensive. I have printed the same parts on both on occasion and the SLA always wins over my printer, visually.

That said, both our printers are capable of almost perfectly matching prints from some of the higher end printers, but they require tweaked slicer settings and mods to stabilize the frame, tweaked jerk and acceleration settings, proper calibration of your extruder, tweaked belt tension, perfectly trammed frame, and things like that.

That was a good idea heating it up to get a better fit!

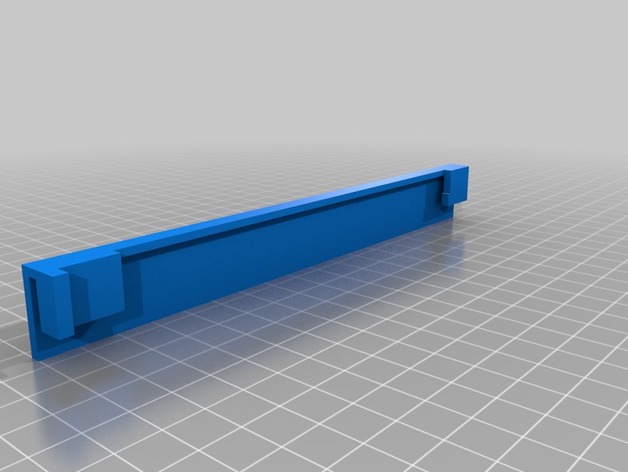

I taught myself Fusion 360 (a major struggle, at my age, but I finally "got it") and have designed all sorts of stupid parts for fixing things around the house, including some items that have been partially broken since the 1970s. Here's a link to some of the parts I've designed:

https://www.thingiverse.com/johnmeyer/designs