April 5th:

I can see the light at the end of the tunnel. Will finish tomorrow, then fire her up and season the smoker. May put some chickens on as they are on sale $0.69/lb. I also have some wild turkey legs and thighs I can smoke with the chickens.

Got the roof finished and installed, edges grinded down, cleaned, brushed with wire wheel, then acid washed. drilled holes for the lag bolts to secure the top. While at lowe's buying the lag bolts, I ran across a 16" wide X 4' roll of fiberglass insulation with no paper backing for $3 bucks. Just enough for the 2" air space in the roof. Being that most of the heat would escape out of the top, figured that was cheap insurance for $3 bucks. I installed the insulation, then bolted the top on.

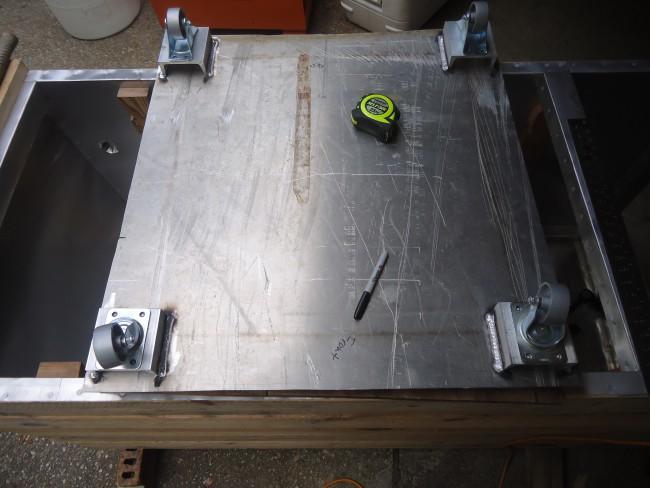

Aluminum roof cleaned and brushed ready to install...

I went with the brushed aluminum look to camoflauge all the scratches in the sheet from the fork lift. It came out looking really good.

Installed...

Compression latches installed...

Door seals very good.

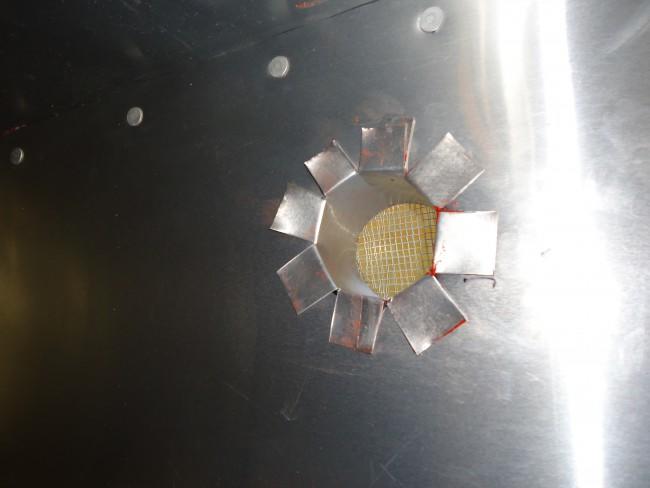

I cut 4 pieces of aluminum flashing 3" X 9 1/4" to install in the 2" vents. I applied high temp silicone then wrapped them into cylinders and taped them into shape with duct tape. slid them into the vent holes, then pushed in 4" drops of 1 1/2 PVC (1 15/16" O.D.) to force them into shape and get good adhesion from the silicone. I will leave them in place until I am ready to fire the smoker up.

I'm going to cut slits down the end of the cylinder and bend the tabs over. I'm cutting some 4" doughnuts out of aluminum plate to make covers to go over the end of the vent to clean it up and get a good seal.

Tomorrow I need to make the covers, then drill some thermometer holes and she's ready to go.