- Oct 2, 2014

- 41

- 10

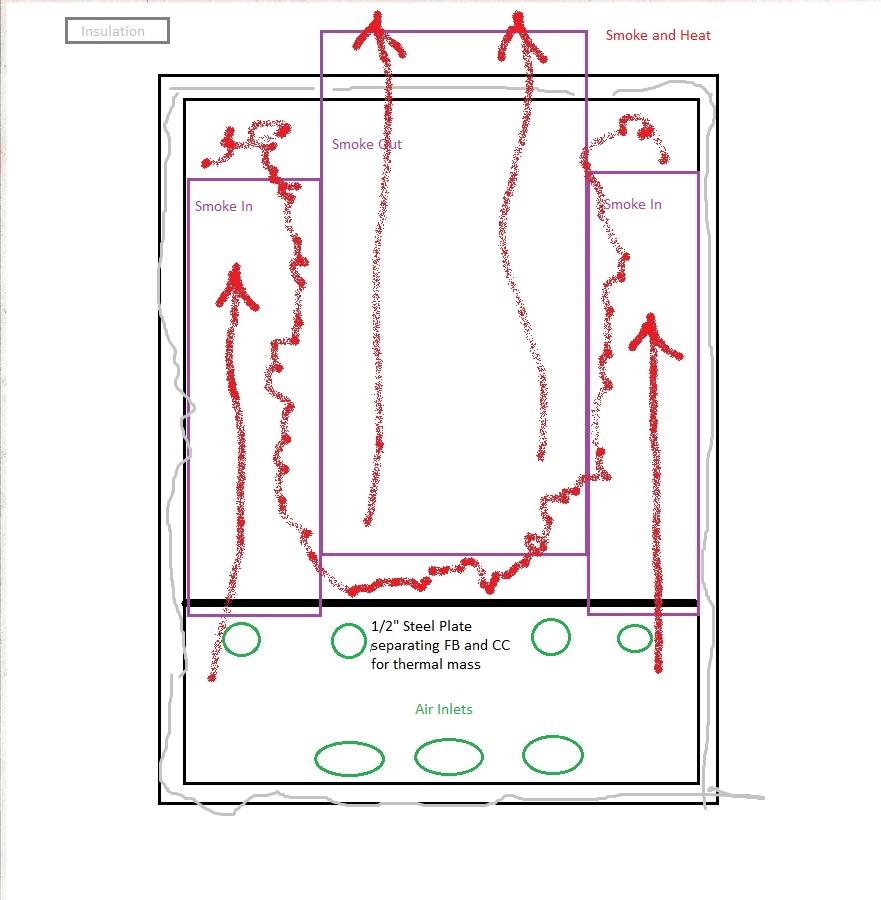

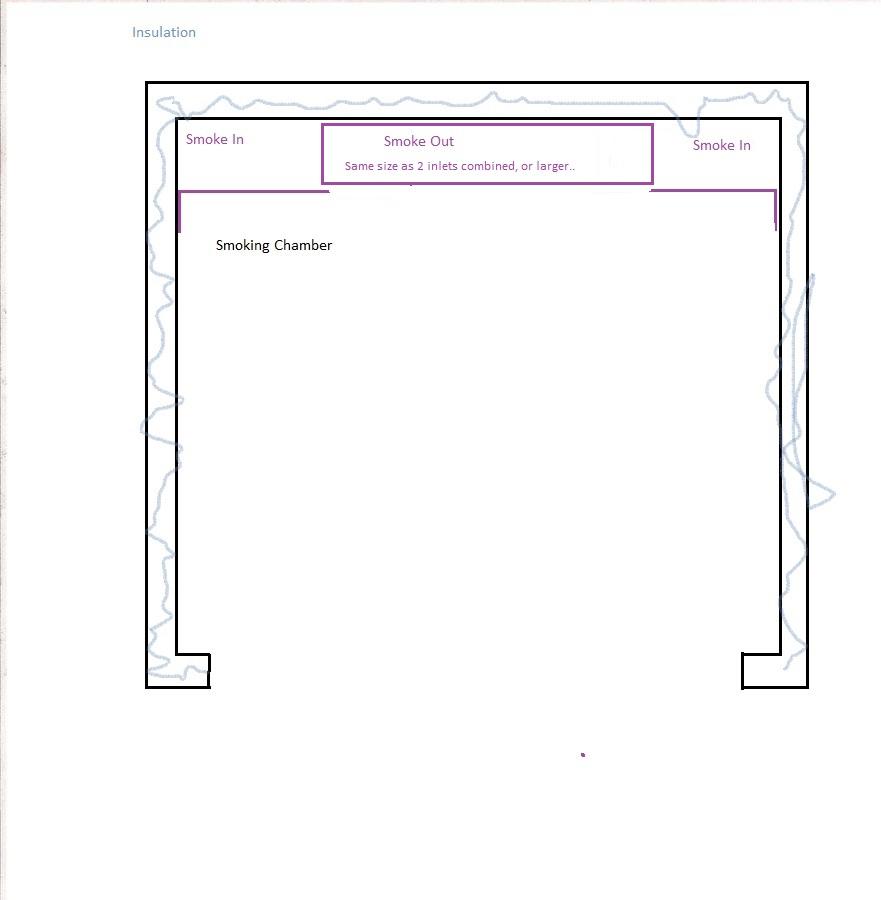

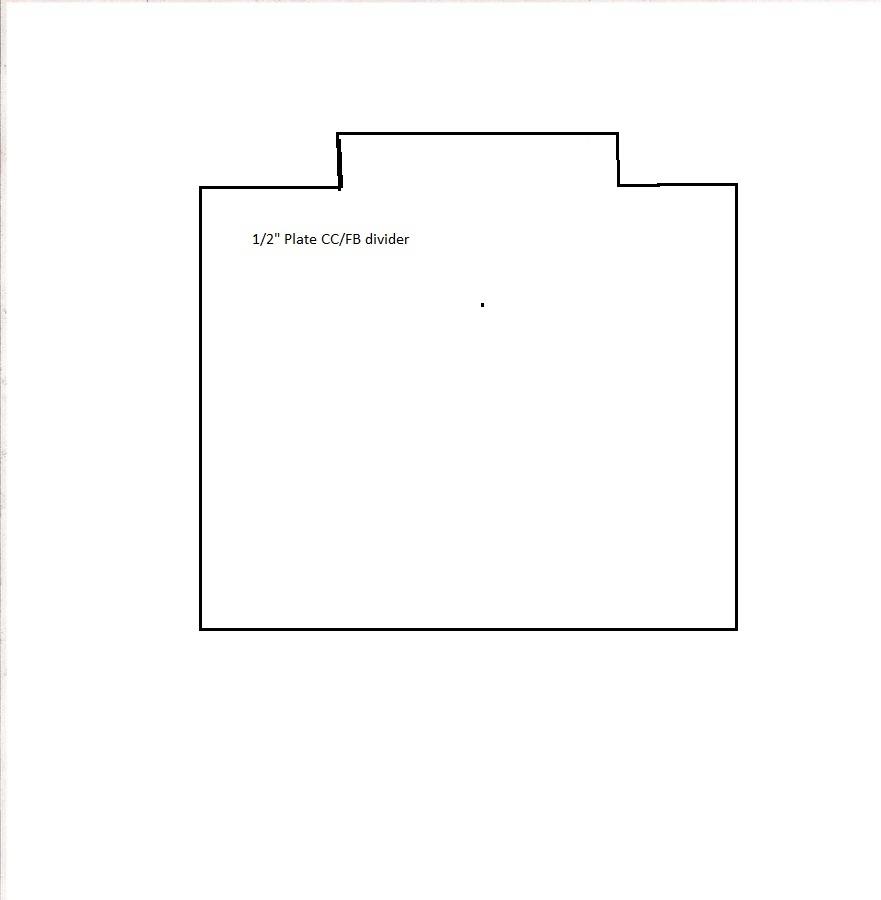

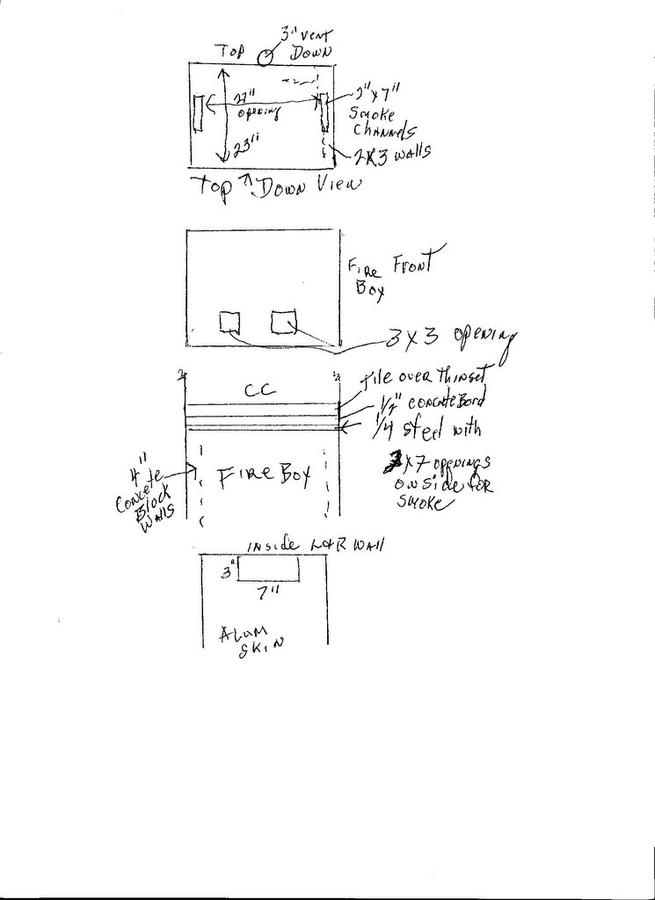

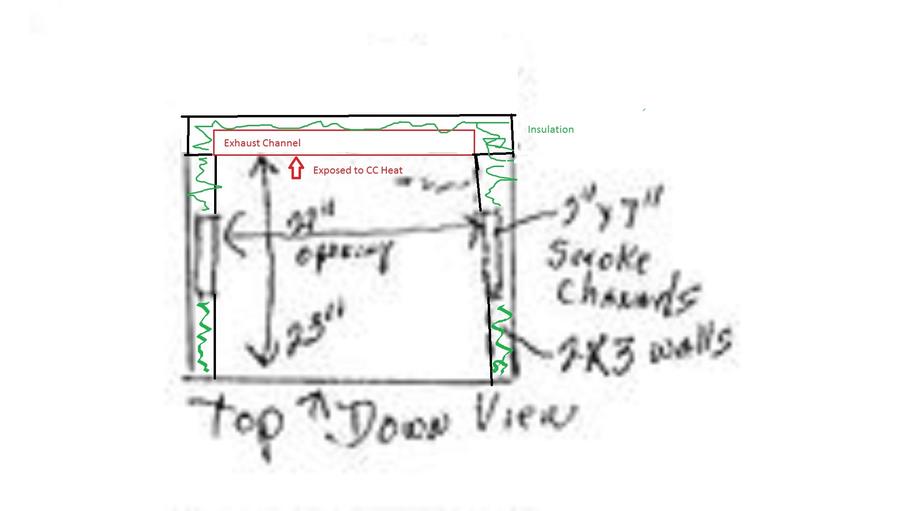

I am having issues with temp control in my VRF smoker. Top is staying way to warm. My smoker is a wood design that is very well insulated and the firebox has steel above it with concrete board and tile with 7 x 2 side channels to the top. I know I have a LOT of mass so I preheat before smoking for 30+ minutes but I still see a 20-30 degree difference. Bottom exit in food box is a 3" opening and food box is ~ 28W x 44H x 22D. I am thinking a bit of convection air may help. I also considered adding a couple ports to the bottom of the side channels

Any ideas or comments appreciated. I like to smoke a lot at 150-180 for my sausage stuff and the wide range of temps is a pain at the moment.

Thanks

Any ideas or comments appreciated. I like to smoke a lot at 150-180 for my sausage stuff and the wide range of temps is a pain at the moment.

Thanks