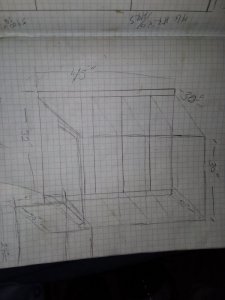

I have been rolling ideas around for some time now. Initially I was going to make a vertical smoker insulated with 1" of clay. The internal was to be 14 gauge hrpo, and skinned with 18 gauge 304 2B stainless.

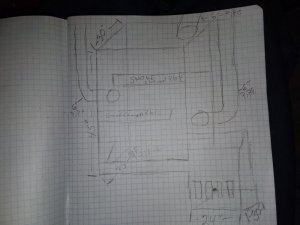

The more I thought on it I figured that it would retain too much heat. So got to thinking about the offset reverse flow. I want to build it larger than needed because it's much more difficult to add space than take away space.

With the new plan I see the CC being 7 gauge,(0.180"). With the FB being 1/4".

Dimensions of the CC are 45" tall, 30" deep, 30" wide.

FB dimensions are 24" tall, 30" deep, 24"wide.

FB to CC 24"x6".

Now here is where it gets tricky. Since I am going larger than needed I am playing with an idea for closing off sections that are not needed with a cover plate to fit into the smoke channel openings.

I am thinking that the first (lowest) being the RF plate that opening being a bit larger than called for so 26"x8". The second direction change opening again larger than needed at 26"x9". With a final direction change opening being 26"x10". Each stage would have an exhaust stack just above grate hight.

I would make a close off plate to fit each of the channel openings. If a section or two is not needed why not just divert to not smoke dead space?

Every day I think on it and change ideas with the new information that I come across.

Next is the grating. I've got a plan that I think is prety cool. We make .223 shell extractors for a company. The skeleton I think would be perfect. It's stainless 13 gauge.

Ok I have been rattling on and on. Pictures below. First drawing was the one to be clad in SS, Then I added the smoke box to see what it may look like.

The second drawing I just drew up to get it out of my head.

The picture is what I plan on using as grates.

The more I thought on it I figured that it would retain too much heat. So got to thinking about the offset reverse flow. I want to build it larger than needed because it's much more difficult to add space than take away space.

With the new plan I see the CC being 7 gauge,(0.180"). With the FB being 1/4".

Dimensions of the CC are 45" tall, 30" deep, 30" wide.

FB dimensions are 24" tall, 30" deep, 24"wide.

FB to CC 24"x6".

Now here is where it gets tricky. Since I am going larger than needed I am playing with an idea for closing off sections that are not needed with a cover plate to fit into the smoke channel openings.

I am thinking that the first (lowest) being the RF plate that opening being a bit larger than called for so 26"x8". The second direction change opening again larger than needed at 26"x9". With a final direction change opening being 26"x10". Each stage would have an exhaust stack just above grate hight.

I would make a close off plate to fit each of the channel openings. If a section or two is not needed why not just divert to not smoke dead space?

Every day I think on it and change ideas with the new information that I come across.

Next is the grating. I've got a plan that I think is prety cool. We make .223 shell extractors for a company. The skeleton I think would be perfect. It's stainless 13 gauge.

Ok I have been rattling on and on. Pictures below. First drawing was the one to be clad in SS, Then I added the smoke box to see what it may look like.

The second drawing I just drew up to get it out of my head.

The picture is what I plan on using as grates.