- Jun 5, 2017

- 24

- 25

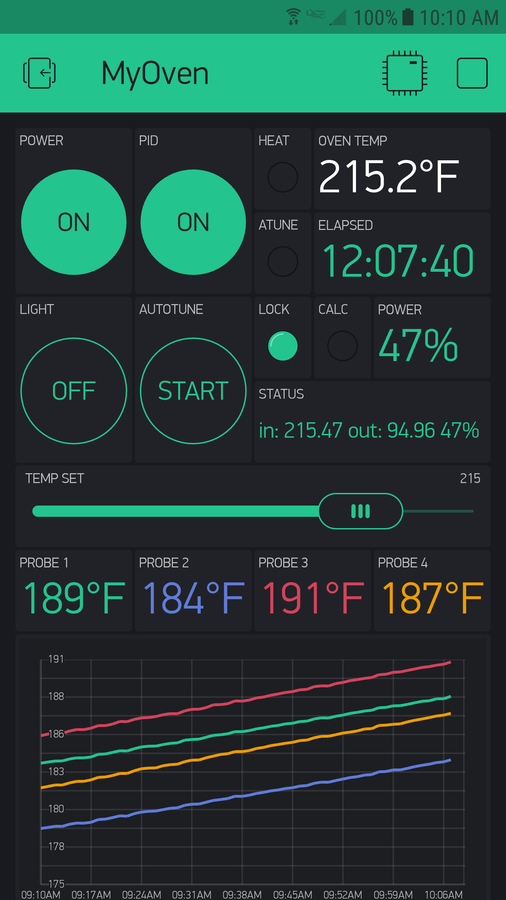

My MES40 gen1 temps were allways a good 20 degrees low, oven could not make 275. I was tired of staying tethered to my smoker. I was tired of only having one meat probe. I decided to make a new controller, to replace the old controller completely. It is working and usable right now. I have smoked in excess of 200 lbs of food with it!

Features:

Full PID control with Autotune built in!! Holds within one or two degrees of setpoint.

Full wireless control from anywhwere through my Android device.

8 probe channels, more precise than Heatermeter, thermistor channels are fully buffered.

No modifications to the oven. Remove old controller, replace with this. Easy to switch back to stock.

No separate power supply.

Exports charts and graphs to email.

Uses only about $20 in parts.

Does not require an SSR modification to achieve full PID Control. Just like in the original design, the power is regulated by relay on/off time. My code uses a special anti relay hammering algorithm I developed that insures the relay is not short cycled while still achieving near perfect temp control.

Not real expensive, but a local Rasberry Pi server is recommended somewhere in the home. The Raspi does not have anything to do with controlling the oven. It has no physical connection to the oven. It is used as a wireless bridge from the internet to the new controller. An internet connected always on PC could also be used, but a Pi is cheaper and lower power.

I am using the excellent Thermoworks Pro-Series probes, SKU: #TX-1003X-AP for oven temp and SKU: #TX-1001X-OP for meats. Got them directly from Thermoworks, about $15 each.

In progress right now:

Use two of the 8 channels to buffer and read the built in MES oven and meat probes.

Select any channel as the oven control channel.

Get notification by text or email when a probe reaches set point. (No screenshot yet)

ToDo:

Create some kind of enclosure.

Probably won't generate much smoke when using the chip box. I use an Amazen. I might add some code to allow more temperature swings, (MES mode lol) which translates to more "on" time for the element.

Currently the project exists as a one off bread board. If there seems to be interest, I can lay it out on a pcb. Maybe sell some boards or a kit. I have the MES40 Gen1. From what I have seen, it should be very easy to port the design to another model.

I am trying to monitor the built in MES probes with two of the 8 available channels. I need the Stienharts for those. I have a curve for the meat probe that works ok. That one doesn't work for the oven. If I could remove the oven probe, I could characterize it or replace it. Doesn't seem to be a way to get behind it. It looks like maybe under one of the serial number plates in the back might expose it?