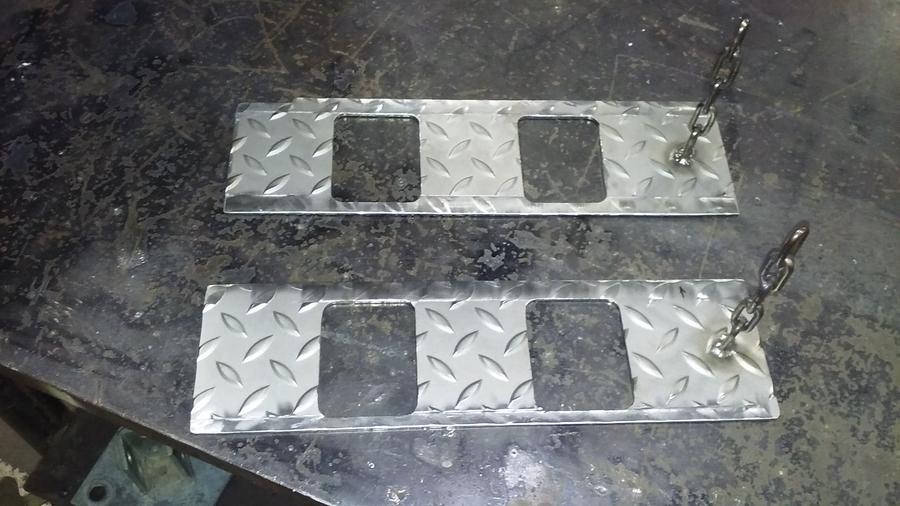

I've been researching build details for a few months since I picked up this water filter tank. It is 304 SS, 30" diameter X 55" long, 3/16" thick. 36944.83 cubic inches. I've built a firebox 27.5 X 24 X 24 from 1/4" steel plate. This is 122% of the recommended size. I have made the 1/2" thick door end 2" bigger all around to have a place to attach the jacketting over the insulation. The opening from the FB to the CC is 155.76 sq in, 27" long 8 3/4" tall with a 1 1/2" grease dam. There are 6 FB intakes 2 1/4 X 3 on the door. I scored some SS 1/8" diamond plate & made the intake sliders from that stock with 3/16" spacers welded to the guides. My chimney will be 6" dia. X 30" long. (24" is recommended). I'll post pics of progress so far. This might take a while to finish, but I'm a detail oriented machinist/welder, and there's no need to rush something that will last a long time.

Stainless cook chamber build Reverse Flow

- Thread starter kingddemo

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

I'm trying to get the pictures to come through instead of a line of code.

Looks like it worked. That is showing the cutout & the chimney will go on the existing 6" hole. Next is fitting the firebox.

Got the last side cut. The door is 18" X 18". The hinges are 1/2" thick.

Made the air vent sliders from SS diamond plate. Milled off the diamonds on the edges.

woodyg

Smoke Blower

ballsonagoose

Newbie

- Feb 27, 2016

- 4

- 10

1967robg

Meat Mopper

north idaho

Fire Starter

Jealous of all that stainless steel, so far only found very expensive sources here.

Your build looks great!

Your build looks great!

Finally got time to insulate and weld the 1/8 steel jacket on the firebox. Used 2' X 4' pieces of 2" thick mineral wool insulation. 3 pieces worked out just right.

Here's a tip. Stick the magnets on the side and use a piece of steel to rest your hand on for steadier welds

Has anybody thought about putting some vent holes on the bottom of the jacket to allow airflow from expansion & contraction due to the repeated heating & cooling?

I had some 20" pipe that I originally planned on being my firebox, but it was too small. I cut 2 pieces of it 6" long to be the wheels. I cut the centers from 2 old trailer wheels & trued them up on the lathe. I'm using 1/2" pipe for the spokes. In order to center it all up, I cut the pipe 1" short & put in a 2" long 5/8 bolt with a nut threaded right up to the head. This allows the hub to be adjusted perfectly centered then weld it all together. The first pic is a hub, spoke & bolt.

I had some 20" pipe that I originally planned on being my firebox, but it was too small. I cut 2 pieces of it 6" long to be the wheels. I cut the centers from 2 old trailer wheels & trued them up on the lathe. I'm using 1/2" pipe for the spokes. In order to center it all up, I cut the pipe 1" short & put in a 2" long 5/8 bolt with a nut threaded right up to the head. This allows the hub to be adjusted perfectly centered then weld it all together. The first pic is a hub, spoke & bolt.

Interested in this as I am getting ready to make 36" and 20" wheels for mine (to look like old tractor wheels)

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 6

- Views

- 3K

- Replies

- 0

- Views

- 613

- Replies

- 0

- Views

- 793

- Replies

- 7

- Views

- 7K

- Replies

- 10

- Views

- 688

Hot Threads

-

Well. Look what Santa dropped off early!

- Started by Steve H

- Replies: 28

- Blowing Smoke Around the Smoker.

-

The Best Egg Salad - Enabler Version

- Started by Chris_in_SoCal

- Replies: 25

- ABT's and all things Appetizers

-

Chicago Cracker-Thin 'Za

- Started by Quiganomics

- Replies: 16

- Pizza

-

Our Thanksgiving Spread

- Started by Colin1230

- Replies: 11

- Blowing Smoke Around the Smoker.