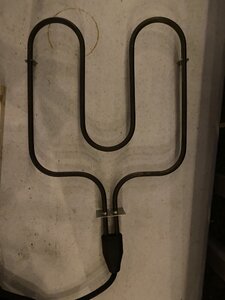

That little mounting plate/tab, where the two elements come back close to each other, is going to get hot. You can't let it touch wood, let alone mount it on wood. I'd say keep at least an inch spacing spacing from any wood, and even then the wood should have some steel sheeting on it to protect it.

I like where you marked the X. That looks like a 2x4? I'd drill a 2-7/8 hole in it and push through a ~6" length of 2.5" EMT conduit. Make it protrude at least 2" into that squarish hole. Cut slots, ~.5" deep, on the inside of that EMT, at 11 o'clock, 1 o-clock, 5 & 7 o'clock. Feed the cord through from the inside, then bend the resulting tabs you cut in the conduit, inward at 90degreees, so you can attach that heating element mounting tab to it with 2 sheet metal screws. On the other (outside) end of the big conduit, keep the cord end centered by epoxying in some glass marbles or even just 3 appropriately-sized rocks. Stuff the remaining open area with some pulled-apart steel wool that will keep hot air from escaping while not offering a major conductive heat path.

And by all means, get some sheet steel (roof flashing is cheap) to mount ~1" under the element to reflect the IR from the lower half of the element UP into the cooking chamber. As I said before, a shield under a shield is even more effective. Look at the catalytic converter on your car to get the idea.