A manual reset thermal limit switch does solve the problem if 350 is the highest temp you will use, but what if you were to want to use your electric smoker to smoke/bake a pizza at 425* etc? A second pid can be set and have the values changed to to 30 degrees (or whatever you wanted to consider an overheat temp) over any temperature you have your element controlling PID set to. I guess when doing LONG smokes (when you likely won't be around to personally monitor the smoke the whole time) the temp isn't going to be much above 220 degrees; therefore, a thermal limit switch would work good. Then when you are using HIGHER temperatures, it will be for a shorter time period when you will be around to monitor the smoke/cook and then you can just JUMP the thermal limit switch out of the circuit and reset it when done.

If the contractor hooked up to the overheat/run-away PID was installed after it's own PID, but BEFORE the smokers element PID, it would turn off the smoker's element PID, and it's SSR and obviously the ELEMENT too.... that is where my theory ends...

Then I assume that when the temps drop below the overheat/run-away set point, the contractor will close the circuit and turn the other PID back on.... so would that PID resume where it left off and go back into an overheat state to then just get turned off until it cools down again and repeat? or when power is reapplied to the PID will it just sit idle?

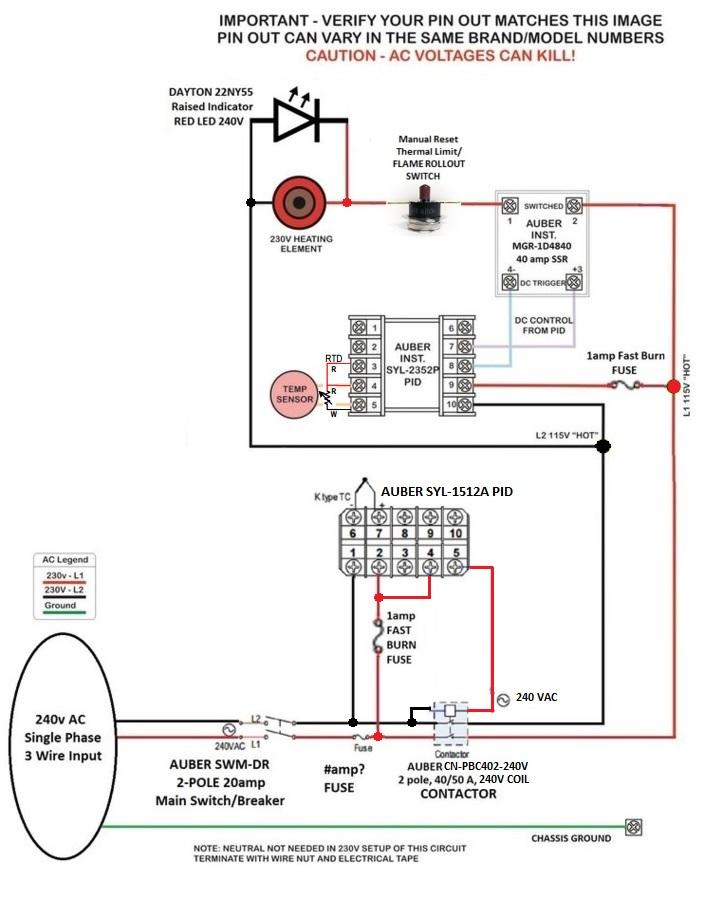

I copied and changed the schematic below to add a secondary PID to control run-away over heat, not sure how it will work. Sorry this isn't with the SMD200, but the SYL-2352P, although it would shut it down the same (if it works?)

I'm guessing this is where a thermal limit switch COULD go? The SSR would still remain active from being failed in a CLOSED state, and then the temperatures would evenually fall, the PID would then send DC voltage to the FAILED SSR. Would the SSR keep getting hotter and eventually physically melt/start fire in this instance even though the circuit AFTER the SSR is OPEN from the thermal limit switch?