Here is the new jewel that I bought today. The tank measures 42" in diameter and is 96" long. I would like to build this smoker as a reverse flow. I want at least 2 sliding racks. I am going to use 5" exhaust. Any help or ideas would be greatly appreciated.

New smoker build

- Thread starter imsmokingpork

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

qwikrnu bbq

Fire Starter

Lots of great ideas in the smoker build threads. Pick a few , add your own twist and roll with it, Take your time. Things seem to take at least three times longer than they should. Any questions, just ask...

va_connoisseur

Smoking Fanatic

Great start. I would use the the bbq calculator (http://www.smokerbuilder.com/pitcalc/) to ensure you get the firebox, vents, correct.

Jeremy, morning...... I'll crunch some numbers for you....

CC .... 42x96=133,000 cu in volume

FB ... 1/3 or larger of the CC 44,000 cu in + 36x36x36 would be a good starting point and could be changed at any time...

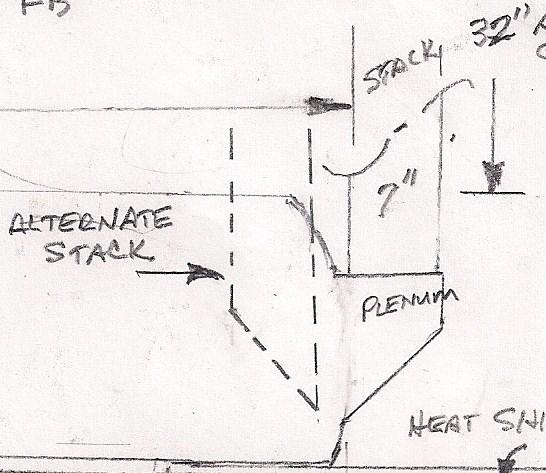

Stack ... 2261 cu in volume using 5" exhaust ... You need 3 stacks that extend 40"+ above the cook chamber.. those can be installed on a single plenum across the end of the CC..

Air inlet FB.... 133 sq in opening... divided into what ever fits.. Less can be used... installed at or below the fire grate in the FB....

Secondary Air inlet above the fire grate across from the FB/CC opening ~ 12-20 sq in... to move heat into the FB...

FB/CC opening... I would make it 400 sq in. 14" segment height on a 21" radiius

RF plate..... same as the FB/CC opening... 14" above the bottom of the CC....

RF plate width... 39.5" wide..... and 11" from the end of the CC.... that gives 435 sq in opening at the end of the RF plate

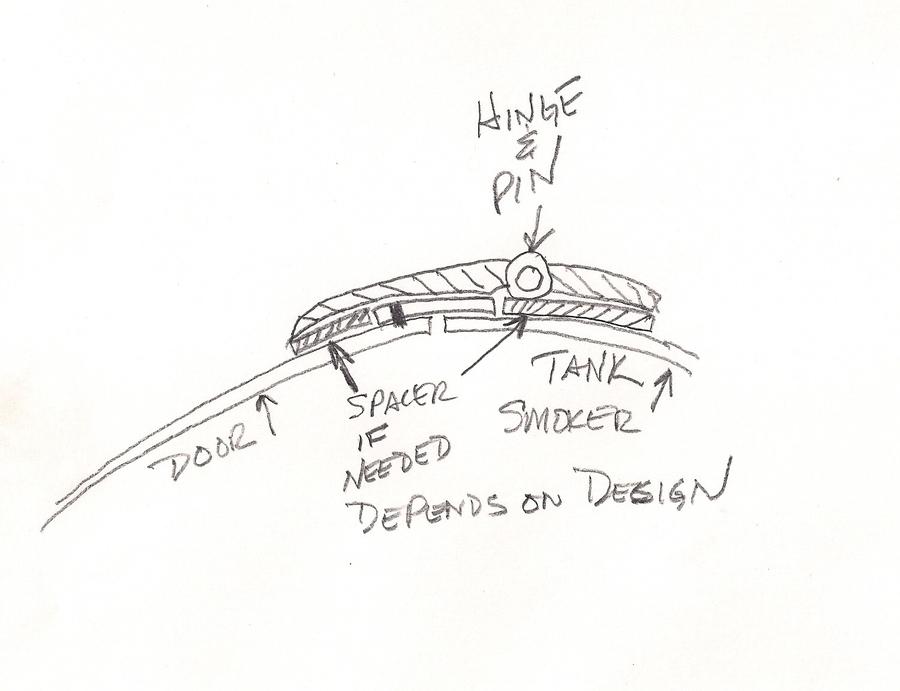

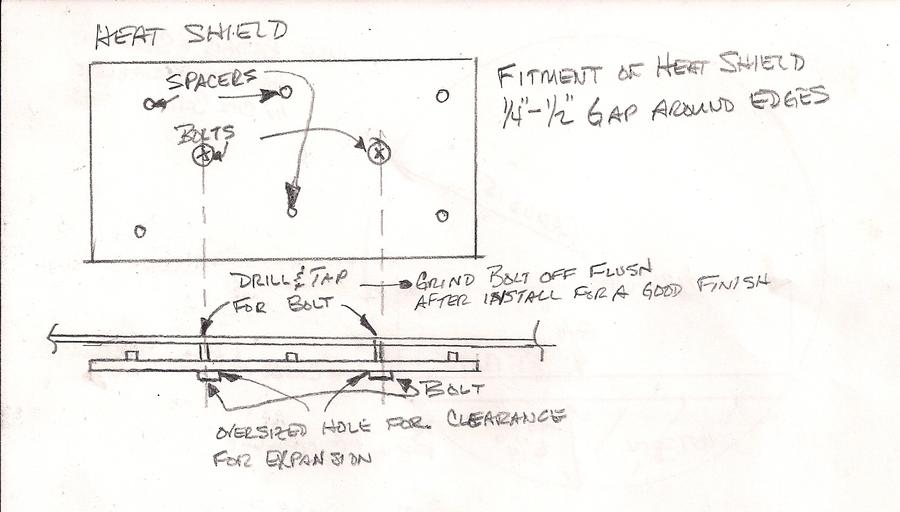

If you want a warming box above the FB, the exhaust stacks could be installed in the end of the CC... FB air inlets something similar to the pics..... Hinge pins need to clear the flange for the door to open properly..... Then you may want a heat shield.....

...Click on pics to enlarge.....

Well, there is a starting point.... ask questions.... our members build some pretty awesome smokers and have great ideas.... Dave

CC .... 42x96=133,000 cu in volume

FB ... 1/3 or larger of the CC 44,000 cu in + 36x36x36 would be a good starting point and could be changed at any time...

Stack ... 2261 cu in volume using 5" exhaust ... You need 3 stacks that extend 40"+ above the cook chamber.. those can be installed on a single plenum across the end of the CC..

Air inlet FB.... 133 sq in opening... divided into what ever fits.. Less can be used... installed at or below the fire grate in the FB....

Secondary Air inlet above the fire grate across from the FB/CC opening ~ 12-20 sq in... to move heat into the FB...

FB/CC opening... I would make it 400 sq in. 14" segment height on a 21" radiius

RF plate..... same as the FB/CC opening... 14" above the bottom of the CC....

RF plate width... 39.5" wide..... and 11" from the end of the CC.... that gives 435 sq in opening at the end of the RF plate

If you want a warming box above the FB, the exhaust stacks could be installed in the end of the CC... FB air inlets something similar to the pics..... Hinge pins need to clear the flange for the door to open properly..... Then you may want a heat shield.....

...Click on pics to enlarge.....

Well, there is a starting point.... ask questions.... our members build some pretty awesome smokers and have great ideas.... Dave

- Jan 6, 2011

- 26,253

- 4,709

That is going to be a nice size smoker 8' long and being that wide I would consider a larger size stack, like Dave did in his drawing, that smoker could handle a 7" or 8" stack with no problem and kinda balance to look. You are going to wind up with a pretty big fire box, so a larger stack would definitely fit right in and look good. Good luck keep us posted on progress and pictures.

Gary

Gary

Thanks for the replies. Dave, u said that the rf plate needs to be 14" above the bottom of the smoker. How far above the rf Plate should I put my first cooking grate? I am wanting to build the best home made rf smoker that smf has seen so far. Any and all ideas comments or questions, please feel free to contact mem if you guys had your choice, would u go with expanded metal cooking surfaces or stainless rods something like a charcoal grill would have...maybe a bit closer together though.

Ps guys. Sorry it took me so long to msg back. I just got off work. Will probably go the same way tomorrow.

Check with others on their preference for grate heights.... Some go by how many racks they can get in the CC to cook more food..... some raise the grate for a more uniform temp.... Some go by the door opening on the CC..... :dunno

Dave

Dave

- Jan 6, 2011

- 26,253

- 4,709

I would put my bottom rack at the door opening level, that way it slides out easy. As far as the other racks think about what you will be cooking and how much head room you need, Also you can add a couple of extra racks( that can be removed) in case you want to do a bunch of ribs, chicken halves or quarters, sausage, or whatever, where you don't need the headroom. And when you do just remove your extra racks.

Gary

Gary

qwikrnu bbq

Fire Starter

I like to keep the first rack right at the bottom of the door opening. In my latest build, the reverse flow plate sits three or four inches under that. I suppose a guy could get away with a little more or less here. When doing rack spacing, if using two levels, I personally like to keep 8-1/2' space between the grates if space permits. Some people prefer to have four levels of racks. In that case I would just space them evenly. After all there's no law saying you have to use all of them.

My choice of cooking surface is stainless expanded; that is if money is no object. Regular nine - 3/4 when seasoned is fine.

My choice of cooking surface is stainless expanded; that is if money is no object. Regular nine - 3/4 when seasoned is fine.

ribwizzard

Master of the Pit

Hey ribwizzard...thanks for chiming in. I highly respect your and Daves opinion. I have read a lot of yalls posts. Now back to the subject at hand...why do you say that sliding racks are so messy? Is it because of the soot and grease on them after cooking with them in and Then having to take them out afterward? Thanks for the comment! Any and all advice is highly appreciated.

ribwizzard

Master of the Pit

You need to make them removable, and sometimes adjustable, ..

I'm just saying that during cooking, some people imagine that they want to slide the rack full of meat out so that they can access the meat during cooking. Not fun, juice and grease dripping all down the front of the cooker and all over your feet. When laying out the design, plan to be able to do all cooking, seasoning, and what ever else you need to do to the meat with the racks in place. If you have to slide out a rack in order to handle the food, your messing up and fixing to have a mess. Leave plenty of room and line of sight when laying out rack spacing. If your doing a very large tank, think about doors on both sides of the tank!

Remember, when feeding people, they want to see clean and sanitary cooking conditions.

I'm just saying that during cooking, some people imagine that they want to slide the rack full of meat out so that they can access the meat during cooking. Not fun, juice and grease dripping all down the front of the cooker and all over your feet. When laying out the design, plan to be able to do all cooking, seasoning, and what ever else you need to do to the meat with the racks in place. If you have to slide out a rack in order to handle the food, your messing up and fixing to have a mess. Leave plenty of room and line of sight when laying out rack spacing. If your doing a very large tank, think about doors on both sides of the tank!

Remember, when feeding people, they want to see clean and sanitary cooking conditions.

- Jan 6, 2011

- 26,253

- 4,709

I agree with the mess, learned that lesson the first time. What I do is take a sheet pan, sit it on my work station, then when I do have to pull out my racks it catches all the drippings. That works for me and my application. Now in saying that I try not to slide them out any more than I have to. Like the old saying "If your Looking you ain't Cooking". Just about every time I smoke the only time I pull my racks out is when I am loading and at the end when everything is coming off, and depending on what I am smoking, I may not pull out the racks then. But the first time or two when I was getting use to my smoker I made a mess pulling out the racks to check my meat, drippings, juice a mess all over my work station boards, patio and running everywhere, didn't take long to figure out I didn't want this mess, Hence the sheet pan.

Gary

Gary

ribwizzard

Master of the Pit

I just figure that if I can keep all the drippings over the reverse flow pan, and drain them out the bottom into a bucket, that's less work for me. I'm ok with giving up a little rack space to keep it looking better.

crazyq

Meat Mopper

i don't know what i'd do without my slide out grates haha. i thot about doing a top slide out and leaving my bottom inside but its just too easy to make em slide out with stops to keep them flat and hanging out and to many advantages over disadvantages not to do it. for me anyways.

its so much easier to slide the grate out, do what i gotta do and slide it back in. my front shelf is solid stainless with a catch on it so all the drippings that do fall on it get wiped right off or drain to the end and end up in a bucket. since your building from scratch, with a little imagination and planning you can build it so there isn't a giant mess to clean up. most of the time it ends up on the ground anyways cause my pits stay parked in the grass or on dirt.

just comes down to personal preference.

its so much easier to slide the grate out, do what i gotta do and slide it back in. my front shelf is solid stainless with a catch on it so all the drippings that do fall on it get wiped right off or drain to the end and end up in a bucket. since your building from scratch, with a little imagination and planning you can build it so there isn't a giant mess to clean up. most of the time it ends up on the ground anyways cause my pits stay parked in the grass or on dirt.

just comes down to personal preference.

Ok I am liking the idea of having slide out racks. I can see why they would be messier. I like having the option of sliding them out should I want to or need to. Does anyone have any good designs for sliding racks? I was thinking about putting some bearings in it some way to make it roll easier when loaded and them have some sort of stop welded in to keep the racks in the smoker lol. I am thinking about every little detail on this smoker because it want it to be the best combination of a whole forum's ideas and tricks. I am doing almost all of the cutting (metal supplier will be making cuts also. What thickness should my reverse flow plate be? I know about the NO GALVANIZED STEEL rule. Any suggestions on handles or counter weights or anything like that, please feel free to om me, comment, email at [email protected] or call me. Pm me for the number. Thanks everyone.

crazyq

Meat Mopper

check out my build for all the ideas i would give you haha. that way you can see them.

once the cooker is season'd the racks will slide on grease basically so no need for complicating them.

i add a piece of metal to the top of the slide that way when i pull them out they stay elevated. i don't add stops because sometimes i take them all the way out to clean or for whatever reason.

i also like RW's idea of adding doors to both sides on very large smokers. i think Lang builds them this way too. but on my 24" smoker its not needed.

once the cooker is season'd the racks will slide on grease basically so no need for complicating them.

i add a piece of metal to the top of the slide that way when i pull them out they stay elevated. i don't add stops because sometimes i take them all the way out to clean or for whatever reason.

i also like RW's idea of adding doors to both sides on very large smokers. i think Lang builds them this way too. but on my 24" smoker its not needed.

ribwizzard

Master of the Pit

On my current build (24" diametric CC ) I installed the front serving rack just under the bottom door flange, the main cooking grate ( grates will be stainless steel round stock) will sit level with bottom lip of door opening. If I'm doing a whole pig or big cuts of meat like butts or brisket, when a sheet pan is placed on the serving rack it will be level with the cooking grate and the meat can be slid from the pan right onto the main cooking grate. I laid it out so that the lip of the large aluminum pans I have actually but right up to the lip on the door opening so that there is no gap.

The top cooking grate ( I will only use two levels on this size dia ) will sit halfway up from the bottom rack. The back of the rack will be hinged at the back wall of the CC, the top rack will now be able to have the front lowered down to cooking grate level for better access to clean it , and that will be the removal position as well, ...or sit lever for the cooking position, or tilted upward with the front of the rack held up against the top of the CC. In the last position , with the rack pushed up against the rear wall of the CC and out of the way, this will give me room for cooking large items like turkey's, etc. with out having to remove the rack from the CC and finding a place to store it. At any time during a cooking cycle, when top rack is needed, it can be tilted down to cooking position , it will already be clean and preheated because it never left the CC .

I'm building this cooker for me, and two racks with the ability to add rib racks to either cooking rack is all the cooking area I need from this one, ...

But, if I was building a larger dia cooker for someone that needed more available cooking area, my thoughts are that by utilizing the stainless round stock instead of 3/4 #9 , the twin racks could be built with inner racks ( think of how a weaving loom opens up ) so that each rack could turn into two racks by lift up the inner rack. Of coarse, you would loose 5 or 6 inches in depth on the inner racks, but shouldn't be that big of deal. Then let's say your cooking a crap load of chicken, it's done and now needs to be placed in pans and kept warm, ...you could just reach in, pull the inner racks forward and the would drop back down to being level with the two main racks and you have room to place your pans back in the cooker!

Just thinking outside the box, and keeping everything inside the CC.

The top cooking grate ( I will only use two levels on this size dia ) will sit halfway up from the bottom rack. The back of the rack will be hinged at the back wall of the CC, the top rack will now be able to have the front lowered down to cooking grate level for better access to clean it , and that will be the removal position as well, ...or sit lever for the cooking position, or tilted upward with the front of the rack held up against the top of the CC. In the last position , with the rack pushed up against the rear wall of the CC and out of the way, this will give me room for cooking large items like turkey's, etc. with out having to remove the rack from the CC and finding a place to store it. At any time during a cooking cycle, when top rack is needed, it can be tilted down to cooking position , it will already be clean and preheated because it never left the CC .

I'm building this cooker for me, and two racks with the ability to add rib racks to either cooking rack is all the cooking area I need from this one, ...

But, if I was building a larger dia cooker for someone that needed more available cooking area, my thoughts are that by utilizing the stainless round stock instead of 3/4 #9 , the twin racks could be built with inner racks ( think of how a weaving loom opens up ) so that each rack could turn into two racks by lift up the inner rack. Of coarse, you would loose 5 or 6 inches in depth on the inner racks, but shouldn't be that big of deal. Then let's say your cooking a crap load of chicken, it's done and now needs to be placed in pans and kept warm, ...you could just reach in, pull the inner racks forward and the would drop back down to being level with the two main racks and you have room to place your pans back in the cooker!

Just thinking outside the box, and keeping everything inside the CC.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 6

- Views

- 3K

- Replies

- 0

- Views

- 869

- Replies

- 3

- Views

- 1K

- Replies

- 3

- Views

- 969

- Replies

- 4

- Views

- 6K

- Replies

- 10

- Views

- 2K

Hot Threads

-

Local To Your Area Recipe Thread?!

- Started by Rafter H BBQ

- Replies: 24

- Blowing Smoke Around the Smoker.

-

Power Out for last 4 days...

- Started by sandyut

- Replies: 23

- Blowing Smoke Around the Smoker.

-

California Roll

- Started by Gonna Smoke

- Replies: 22

- ABT's and all things Appetizers

-

Piedmontese deal

- Started by Steve H

- Replies: 20

- Blowing Smoke Around the Smoker.