I posted here http://www.smokingmeatforums.com/t/232880/need-advise-on-1st-smokehouse-build

a few months back wanting DaveOmak to comment. Didn’t hear from him so I went with what I thought would be the best application for me. I figured it was just as easy to build a small one as it was to build a larger one.

I didn’t use any plans, just built it as I went. I went with this size so it would fit on my utility trailer if I wanted to move it. I own my on property but couldn't decide on its location. I thought it could be made "portable" so I could haul it to different events if I wanted to. Plus this way I would get more cooking area out of it. So I put it on treated skids, so it would be easier to relocate.

I wanted the Smokehouse to appear Old so I used mostly old oak from an Old Building that was taken down in Fruitvale Texas for the frame and 6” tongue & groove taken from the ceiling, for the outside of smokehouse. The 2X4 s are rough cut and actual 2X4 in dimension.

So I started laying it out making sure all was level and squared up. I started with 4 X 6 treated skids for portability.The Skid was the only treated wood used on build.

Designs I based the look and function of My Smokehouse on are:

Pops6927 http://www.smokingmeatforums.com/t/88853/found-a-burner-for-smokehouse

jarjarchef http://www.smokingmeatforums.com/t/136196/not-so-mini-smokehouse-build-w-pics

Hagisan http://www.smokingmeatforums.com/t/135339/smokehouse-build

kenn1320 http://www.smokingmeatforums.com/t/174038/michigan-insulated-smoke-house

Or this one: http://animalscience.uconn.edu/extension/publications/build_smokehouse.pdf

Thanks to all above for inspiring me.

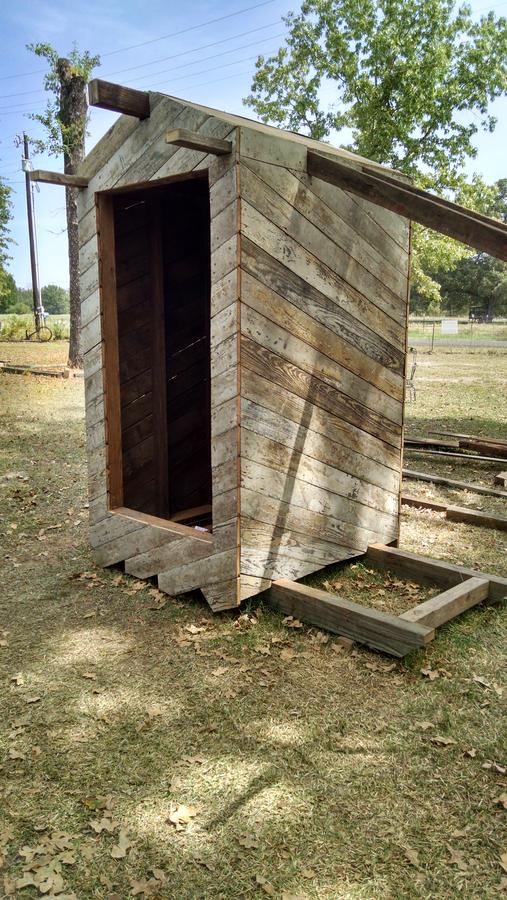

Dimensions are 4'x5'x7 ½ '. I used slanted cuts of wood for strength mainly but in the end like the way it looks too.

Layed out the skid making sure all level and square

Used 4x6 and 4x4 treated pieces I had laying around for cross braces and nailed in with barn nails.

Layed out bottom of Smokehouse with some old 2X6 I had in barn.

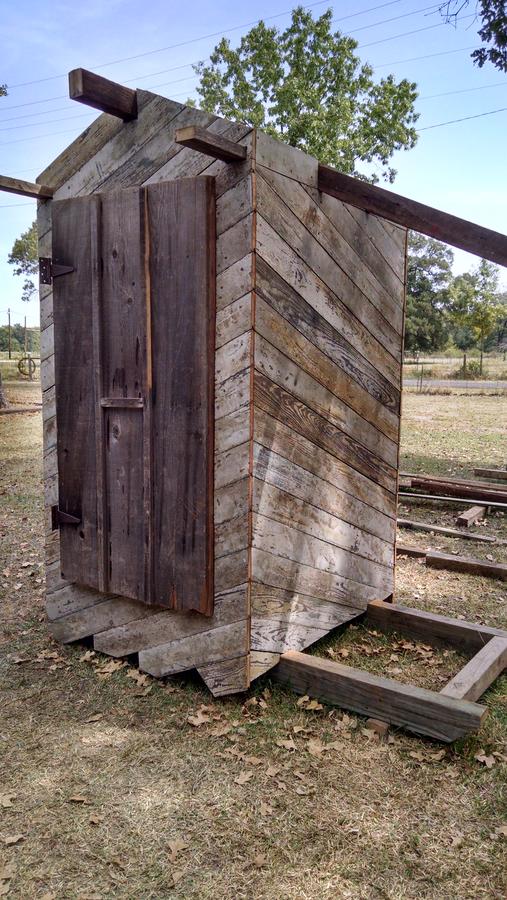

I was driving and missed my turn and while turning around, I noticed a man with a lot of old barn wood in his yard. I stopped to ask if it was for sale, thinking all he could do was say yes or no, and spotted this old batten barn door. He sold it to me for $5. I grabbed it up, paid him, and drove off before he could change his mind.

The door was semi strong but thinking of how much it would be opened and closed, I decided to put a 2x4 frame on the back of it to strengthen it up. Fame in picture is just laying on a plywood table. Plywood is not part of the door. As you can see, I'm using deck screws on construction. I think they are way better than nails and believe if old timers had access to them, they would have preferred them to nails too.

I got lost in the build for a time and forgot to take pictures. As soon as I remembered to take pics, I was to this stage. I'm also working by myself so Im using the T posts, at this point, as a helping hand for roof rafter support.

I installed door frame temporarily to make sure all was level and square and attached cross braces to hold it that way. I also measured cross cornered on base and top to make sure measurements were same. I used untreated plywood for roof of Smokehouse. I also built a access door to the rear of Smokehouse so I could use full barn door on front.

6” tongue & groove attached to all sides. I used the same angle on the boards as the angle of the roof. Boards at a 45 just didnt look as good ad board angle matching the roof angle, to me. Some of the old tounge & groove has some of the tongue missing, as pic shows some small spaces viewing from inside out. I started to batten it from inside but after reading DaveOmak's comments on this issue from other threads, might leave it alone so it can breath. Comments?

Outside mostly completed, boards need trimmed, with floor registers as vents.

Checking door jam fit. I did decide to design an roof overhand on this build. It will overhang 16" when finished. It will help in keeping rain out of Smokehouse and give it a little uniqueness. 1¼" holes will be drilled at each end of skid 4 X 6's for installation of a horizontal 1'' "sucker rod" to use for towing the Smokehouse.

Attached door, roof supports and some old used corrugated metal for roof. I patched any existing holes in metal roofing before I installed it. I was going to trim corners with 1" trim but when I placed it before attaching, it took away from the lines of the angles of the boards. I like it better untrimmed.

Is that smoke? Yes it is. I couldn't wait until I could afford the meat to put in it, so I fired up a small potbelly stove I had in barn, to test how she smoked.

It was raining this day and all wood was wet, plus I watched it the whole time to make sure my potbelly stove inside wasn't creating a disaster. I am thinking of installing a heat shield to the inside bottom 3rd of walls, of some type, before completion to make sure that when I use either the potbelly stove or a burner inside, that all is adequately fire protected.

A little smoke escaping from the boards where the tongue is missing.

Potbelly is sitting on an old discarded aluminum street sign that with a little work, and some some removable 2X12's, will be the floor to keep out varmits.

I got the potbelly fired up as much as it would go to check highest temp and volume of smoke. Smoke was great and temp got up to 150F . Temp stayed for 2 hrs with door shut and smoke needed a little addition of wood to keep it up, but overall Ok.

Smokehouse mostly finished on outside. Still going to add wood racks, as others have done, under roof.

The old building had square nails in the wood and from doing some research it seems this dates the wood from the old building to pre 1900s. http://www.appaltree.net/aba/nails.htm and when an early wrought iron nail corrodes, or rusts, it leaves a black stain in the wood around the nail hole. Newer nails because of their composition leaves a red stain around the nail hole.

I built this Smokehouse with materials I had already stored around my farm. The only expense I had was buying around $75 worth of deck screws and the $5 door. I have all I need to finish inside also.

I'm still experimenting with different heat sources. Im thinking of adding a 4X8 oven glass viewing window in front door. Also thinking of installing an old ceramic light fixture inside for light, when needed. Any thoughts?

Small potbelly can maintain 150 for a few hours but I’m planning on installing a permanent black pipe thru outside wall to inside for propane burner, when needed.

I know from reading other threads on this forum, and others, that this question is controversial but..............I've done some research that suggests it is OK to use Durock brand Next Gen Cement Board or even corrugated metal, or both, for a heat shield in bottom inside of Smokehouse as long as the meat doesn't come in contact with either. I am thinking of going this direction. Any new thoughts?

I will start on inside soon and post pics as the build progresses.

Thanks to all who inspired me.

a few months back wanting DaveOmak to comment. Didn’t hear from him so I went with what I thought would be the best application for me. I figured it was just as easy to build a small one as it was to build a larger one.

I didn’t use any plans, just built it as I went. I went with this size so it would fit on my utility trailer if I wanted to move it. I own my on property but couldn't decide on its location. I thought it could be made "portable" so I could haul it to different events if I wanted to. Plus this way I would get more cooking area out of it. So I put it on treated skids, so it would be easier to relocate.

I wanted the Smokehouse to appear Old so I used mostly old oak from an Old Building that was taken down in Fruitvale Texas for the frame and 6” tongue & groove taken from the ceiling, for the outside of smokehouse. The 2X4 s are rough cut and actual 2X4 in dimension.

So I started laying it out making sure all was level and squared up. I started with 4 X 6 treated skids for portability.The Skid was the only treated wood used on build.

Designs I based the look and function of My Smokehouse on are:

Pops6927 http://www.smokingmeatforums.com/t/88853/found-a-burner-for-smokehouse

jarjarchef http://www.smokingmeatforums.com/t/136196/not-so-mini-smokehouse-build-w-pics

Hagisan http://www.smokingmeatforums.com/t/135339/smokehouse-build

kenn1320 http://www.smokingmeatforums.com/t/174038/michigan-insulated-smoke-house

Or this one: http://animalscience.uconn.edu/extension/publications/build_smokehouse.pdf

Thanks to all above for inspiring me.

Dimensions are 4'x5'x7 ½ '. I used slanted cuts of wood for strength mainly but in the end like the way it looks too.

Layed out the skid making sure all level and square

Used 4x6 and 4x4 treated pieces I had laying around for cross braces and nailed in with barn nails.

Layed out bottom of Smokehouse with some old 2X6 I had in barn.

I was driving and missed my turn and while turning around, I noticed a man with a lot of old barn wood in his yard. I stopped to ask if it was for sale, thinking all he could do was say yes or no, and spotted this old batten barn door. He sold it to me for $5. I grabbed it up, paid him, and drove off before he could change his mind.

The door was semi strong but thinking of how much it would be opened and closed, I decided to put a 2x4 frame on the back of it to strengthen it up. Fame in picture is just laying on a plywood table. Plywood is not part of the door. As you can see, I'm using deck screws on construction. I think they are way better than nails and believe if old timers had access to them, they would have preferred them to nails too.

I got lost in the build for a time and forgot to take pictures. As soon as I remembered to take pics, I was to this stage. I'm also working by myself so Im using the T posts, at this point, as a helping hand for roof rafter support.

I installed door frame temporarily to make sure all was level and square and attached cross braces to hold it that way. I also measured cross cornered on base and top to make sure measurements were same. I used untreated plywood for roof of Smokehouse. I also built a access door to the rear of Smokehouse so I could use full barn door on front.

6” tongue & groove attached to all sides. I used the same angle on the boards as the angle of the roof. Boards at a 45 just didnt look as good ad board angle matching the roof angle, to me. Some of the old tounge & groove has some of the tongue missing, as pic shows some small spaces viewing from inside out. I started to batten it from inside but after reading DaveOmak's comments on this issue from other threads, might leave it alone so it can breath. Comments?

Outside mostly completed, boards need trimmed, with floor registers as vents.

Checking door jam fit. I did decide to design an roof overhand on this build. It will overhang 16" when finished. It will help in keeping rain out of Smokehouse and give it a little uniqueness. 1¼" holes will be drilled at each end of skid 4 X 6's for installation of a horizontal 1'' "sucker rod" to use for towing the Smokehouse.

Attached door, roof supports and some old used corrugated metal for roof. I patched any existing holes in metal roofing before I installed it. I was going to trim corners with 1" trim but when I placed it before attaching, it took away from the lines of the angles of the boards. I like it better untrimmed.

Is that smoke? Yes it is. I couldn't wait until I could afford the meat to put in it, so I fired up a small potbelly stove I had in barn, to test how she smoked.

It was raining this day and all wood was wet, plus I watched it the whole time to make sure my potbelly stove inside wasn't creating a disaster. I am thinking of installing a heat shield to the inside bottom 3rd of walls, of some type, before completion to make sure that when I use either the potbelly stove or a burner inside, that all is adequately fire protected.

A little smoke escaping from the boards where the tongue is missing.

Potbelly is sitting on an old discarded aluminum street sign that with a little work, and some some removable 2X12's, will be the floor to keep out varmits.

I got the potbelly fired up as much as it would go to check highest temp and volume of smoke. Smoke was great and temp got up to 150F . Temp stayed for 2 hrs with door shut and smoke needed a little addition of wood to keep it up, but overall Ok.

Smokehouse mostly finished on outside. Still going to add wood racks, as others have done, under roof.

The old building had square nails in the wood and from doing some research it seems this dates the wood from the old building to pre 1900s. http://www.appaltree.net/aba/nails.htm and when an early wrought iron nail corrodes, or rusts, it leaves a black stain in the wood around the nail hole. Newer nails because of their composition leaves a red stain around the nail hole.

I built this Smokehouse with materials I had already stored around my farm. The only expense I had was buying around $75 worth of deck screws and the $5 door. I have all I need to finish inside also.

I'm still experimenting with different heat sources. Im thinking of adding a 4X8 oven glass viewing window in front door. Also thinking of installing an old ceramic light fixture inside for light, when needed. Any thoughts?

Small potbelly can maintain 150 for a few hours but I’m planning on installing a permanent black pipe thru outside wall to inside for propane burner, when needed.

I know from reading other threads on this forum, and others, that this question is controversial but..............I've done some research that suggests it is OK to use Durock brand Next Gen Cement Board or even corrugated metal, or both, for a heat shield in bottom inside of Smokehouse as long as the meat doesn't come in contact with either. I am thinking of going this direction. Any new thoughts?

I will start on inside soon and post pics as the build progresses.

Thanks to all who inspired me.

Last edited: