I finally got to auto tune the Mes Gen 1 40 with the Auber WS-1510ELPM at 275*F. It got my parameters to P= 34, I=282 and D=70 in 53 minutes. This resulted in the controller coming out of full power way too early. I auto tuned again and same results. The instructions said this unit operates in these modes:

on/off mode is P=0

PID mode is P=>0, I=>0, D=>0

PI mode is P=>0, I=>0, D=0

PD mode is P=>0, I=0, D=>0

P mode is P=>0, I=0, D=0

My smoker interior setup is an open design inside for unrestricted air circulation for even heating left to right on the top three racks: Open/exposed heating element. water pan on bottom rack with perforated stainless steel underneath it butt up against length of back wall. This I'll never change because the results are too good and may differentiate my smoker from all others and how I need to use my Auber controller.

In P mode if P=7, then 7 degrees below set temp: output=100%, 5 degrees below set temp: output=71% and set temp: output=0%.

Then if P=2, then 2 degrees below set temp: output=100%, 1 degree below set temp: output=50% and set temp=0%.

The lowest setting P=1 with this mode keeps my smoker within 2 degrees of my set temp. This is the same as a Mes controller that you can ramp down (if you have lower air flow than mine) as it approaches the set temp with the sensor next to your food to get any temp you want. Now that is BEAUTIFUL! Having max output to a specific degree you choose, then it ramps down to your set temp.

Since this is full throttle output to your degree of choice, setting temp to 15*F below your desired cooking temp is done on preheating. It'll coast up after the controller shuts off and as it slows then reset the temp to your desired cooking temp (Bear's manual no/low over shoot solution) ie. if you want to cook at 275*F preheat to 260*F. When the controller shuts off at 260*F the heating momentum will coast up to around 275*F in a minute or two, then reset the controller to 275*F. This will need to be done after opening the door as well. Just having the probe in open air at your food level makes all the difference with this mode. I need more full power for my smoker and I'm really liking this mode. I smoked salmon on the second rack from the top starting at 150*F for a couple hours without having to change the P value from when it was running at 275*F.

Barely see the perf ss butt against back wall behind water pan.

Can't see perf ss in this pic. Not much of it is really used because the water pan is on top of the part that comes to the center of the rack and none of it infront. Rib pic from the past but shows open area below water pan. Moves heat left with air flow from chip loader hole.

Today's Salmon.

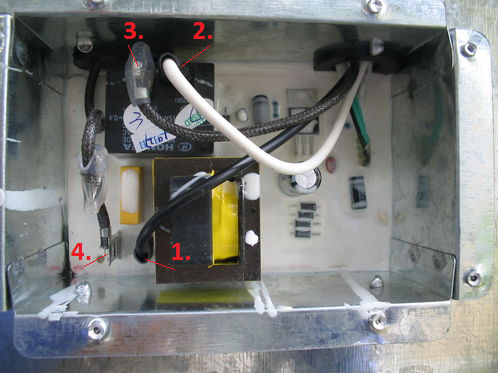

Numbers don't show on PID in pics.

145*f left and right. To me even temps and getting to 275+*f is what I needed. The tighter offset is just a bonus with the PID.

on/off mode is P=0

PID mode is P=>0, I=>0, D=>0

PI mode is P=>0, I=>0, D=0

PD mode is P=>0, I=0, D=>0

P mode is P=>0, I=0, D=0

My smoker interior setup is an open design inside for unrestricted air circulation for even heating left to right on the top three racks: Open/exposed heating element. water pan on bottom rack with perforated stainless steel underneath it butt up against length of back wall. This I'll never change because the results are too good and may differentiate my smoker from all others and how I need to use my Auber controller.

In P mode if P=7, then 7 degrees below set temp: output=100%, 5 degrees below set temp: output=71% and set temp: output=0%.

Then if P=2, then 2 degrees below set temp: output=100%, 1 degree below set temp: output=50% and set temp=0%.

The lowest setting P=1 with this mode keeps my smoker within 2 degrees of my set temp. This is the same as a Mes controller that you can ramp down (if you have lower air flow than mine) as it approaches the set temp with the sensor next to your food to get any temp you want. Now that is BEAUTIFUL! Having max output to a specific degree you choose, then it ramps down to your set temp.

Since this is full throttle output to your degree of choice, setting temp to 15*F below your desired cooking temp is done on preheating. It'll coast up after the controller shuts off and as it slows then reset the temp to your desired cooking temp (Bear's manual no/low over shoot solution) ie. if you want to cook at 275*F preheat to 260*F. When the controller shuts off at 260*F the heating momentum will coast up to around 275*F in a minute or two, then reset the controller to 275*F. This will need to be done after opening the door as well. Just having the probe in open air at your food level makes all the difference with this mode. I need more full power for my smoker and I'm really liking this mode. I smoked salmon on the second rack from the top starting at 150*F for a couple hours without having to change the P value from when it was running at 275*F.

Barely see the perf ss butt against back wall behind water pan.

Can't see perf ss in this pic. Not much of it is really used because the water pan is on top of the part that comes to the center of the rack and none of it infront. Rib pic from the past but shows open area below water pan. Moves heat left with air flow from chip loader hole.

Today's Salmon.

Numbers don't show on PID in pics.

145*f left and right. To me even temps and getting to 275+*f is what I needed. The tighter offset is just a bonus with the PID.

![DSC_0303[1].JPG](/media/dsc_0303-1-jpg.528634/full?d=1507244980)

![DSC_0302[1].JPG](/media/dsc_0302-1-jpg.528632/full?d=1507244980)