About a month ago I posted a thread about this very subject and the advice I received was a great help.

I have temporarily installed a 1500 watt dimmer switch to check out my mod.

IT WORKS !!!!!!!

Now I will have to finish the install correctly but I could not wait, until then, to post so here it is.

First, check your outlet for correct polarity. I am showing a device that tells you if it is correct by lighting up 2 yellow lights. The wide spade is the neutral. The narrow spade is the 110 volt hot side. This can be accomplished with a multimeter. The hot leg will show 110 v to the ground leg. If the ground leg is down, the hot is on the right.

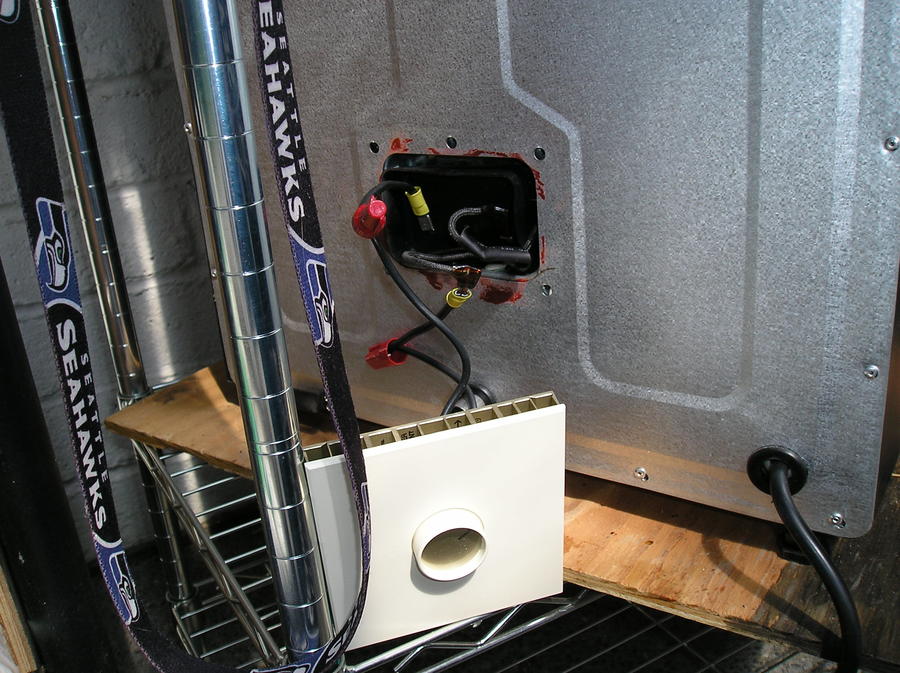

Unplug the smoker and remove the element cover plate. On my smoker, the hot wire is coming in from the bottom of the box.

I removed both shrink tubings and both wires from the element to check stuff out.

Then I plugged the smoker back in with the element disconnected. All the controls still worked letting me know the element is not in the circuit for the controls. One wire was hot with 110 v. That is the wire I connected to the dimmer. Then I connected a wire from the other side of the dimmer to the element and reconnected the neutral wire, in the smoker, back to the remaining leg on the element.

For your info: The 800 watt element had 21 OHMS resistance.

Here you might be able to see the wire coming from the bottom of the box to the dimmer and then to the element. The neutral connected back to the element also. Short jumper wires were used for this test. Which side of the elements you reconnect the wires is not important to the element operating correctly. It may be important when you feed the wires into whatever conduit you use.

I plan on using a step drill, in the cover plate, to facilitate the attachment of the flex conduit I plan on installing.

My check of the operation of the dimmer showed @30 VAC the element operated at approx 320* F over a 15 min test.

I am not sure what temp chips will smoke but that should be close. Tinkering will tell.

I will have to make another chip pan. One that sits directly on the element so heat transfer will get them smoldering at a lower setting. Leaving the chip dispenser tube out and the top vent wide open should allow for a cooler smoking temp and good air flow.

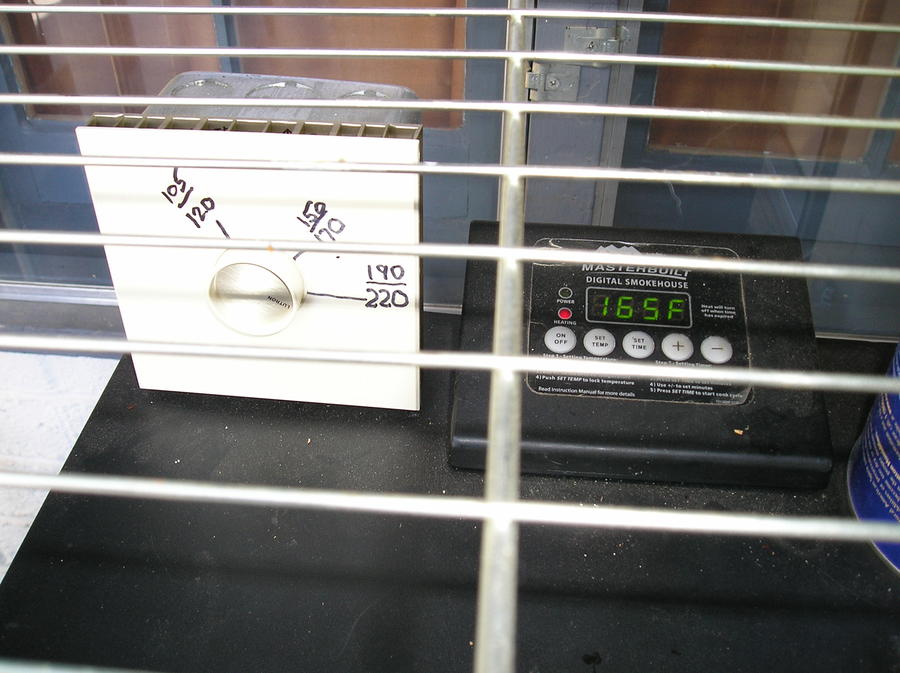

Below is the dimmer I used. I know the element is 800 watts. I chose the 1500 so as to not overheat the dimmer. I guess you could call it a safety factor.

After all is said and done, my original purpuse for this mod was to slow the temp swings. With any luck, settings will be found to operate at desired temps with little or no overtemp swings. Other benefits may surface. Time will tell.

I have temporarily installed a 1500 watt dimmer switch to check out my mod.

IT WORKS !!!!!!!

Now I will have to finish the install correctly but I could not wait, until then, to post so here it is.

First, check your outlet for correct polarity. I am showing a device that tells you if it is correct by lighting up 2 yellow lights. The wide spade is the neutral. The narrow spade is the 110 volt hot side. This can be accomplished with a multimeter. The hot leg will show 110 v to the ground leg. If the ground leg is down, the hot is on the right.

Unplug the smoker and remove the element cover plate. On my smoker, the hot wire is coming in from the bottom of the box.

I removed both shrink tubings and both wires from the element to check stuff out.

Then I plugged the smoker back in with the element disconnected. All the controls still worked letting me know the element is not in the circuit for the controls. One wire was hot with 110 v. That is the wire I connected to the dimmer. Then I connected a wire from the other side of the dimmer to the element and reconnected the neutral wire, in the smoker, back to the remaining leg on the element.

For your info: The 800 watt element had 21 OHMS resistance.

Here you might be able to see the wire coming from the bottom of the box to the dimmer and then to the element. The neutral connected back to the element also. Short jumper wires were used for this test. Which side of the elements you reconnect the wires is not important to the element operating correctly. It may be important when you feed the wires into whatever conduit you use.

I plan on using a step drill, in the cover plate, to facilitate the attachment of the flex conduit I plan on installing.

My check of the operation of the dimmer showed @30 VAC the element operated at approx 320* F over a 15 min test.

I am not sure what temp chips will smoke but that should be close. Tinkering will tell.

I will have to make another chip pan. One that sits directly on the element so heat transfer will get them smoldering at a lower setting. Leaving the chip dispenser tube out and the top vent wide open should allow for a cooler smoking temp and good air flow.

Below is the dimmer I used. I know the element is 800 watts. I chose the 1500 so as to not overheat the dimmer. I guess you could call it a safety factor.

After all is said and done, my original purpuse for this mod was to slow the temp swings. With any luck, settings will be found to operate at desired temps with little or no overtemp swings. Other benefits may surface. Time will tell.

Last edited: