Commonly it's called "niter" or "sugar sand". Most people fight with this and solve the issue in various ways, mainly filtering.

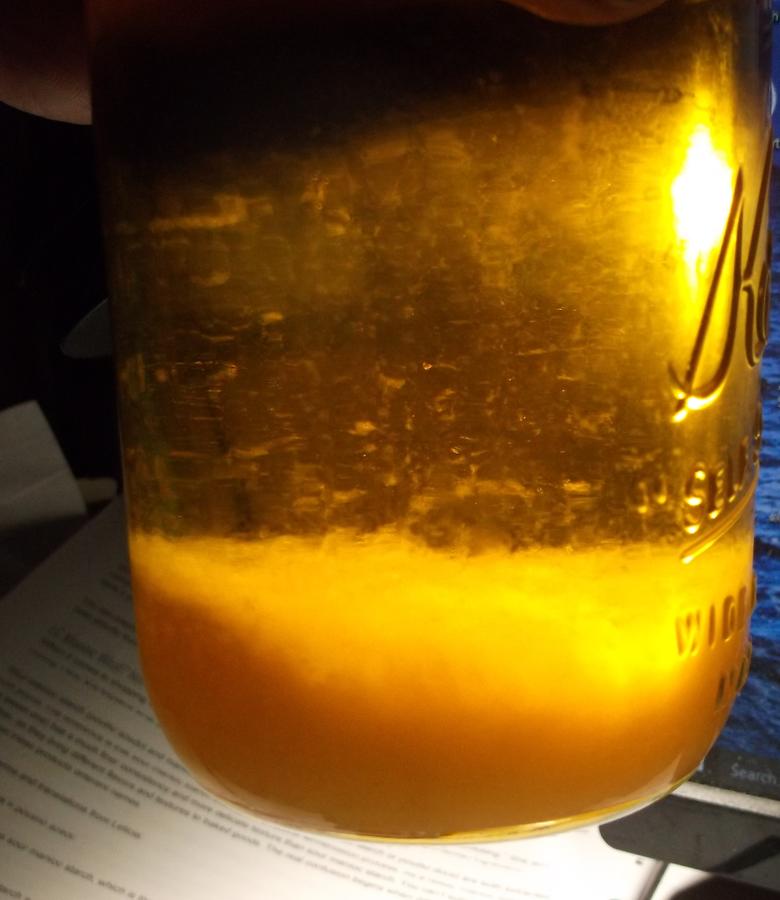

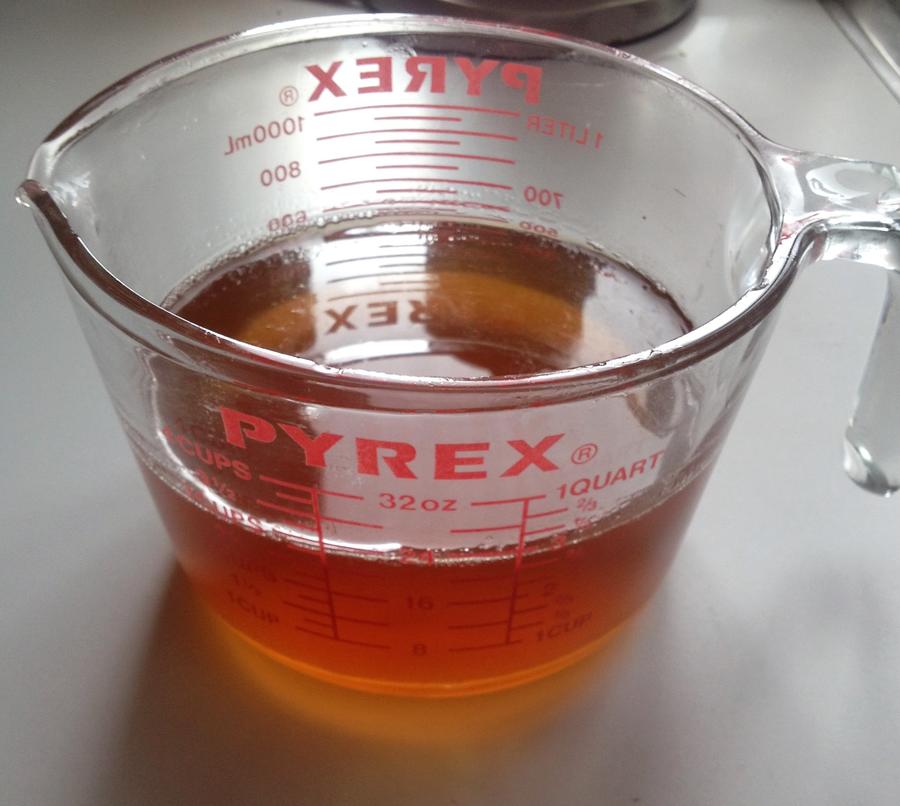

After trying lots of ways to fix it on a small scale, I finally decided to just let it settle out to the bottom of the jar, and then decant the clear off of the top. Then, I will heat the remaining nitered syrup and filter it as best I can, back into the next boil. It clogs up the filter pretty quick though and gets to be a pain.

If you are going to heat up your clear syrup in order to can it, do not take it over 190 or more niter will form and you will have the same issue.

I think this niter is what gives some of my syrup the "off flavor". If I leave the settled niter in the jar too long, it seems like the syrup takes on a funny after taste.

You can do a lot of research and hear a lot of suggestions on removing niter, you just need to figure out what works for you and what final product your happy with. The big operations use filter presses, some smaller processors use jelly cloth, some use wool filters, there are special filters you can buy, etc etc.

I just keep "recycling" as much as I can back into the next batch, and try to leave my "loss" for the very last batch. (I rinse out all of my pans, strainers, ladels, cloths, etc in the next sap batch cooking to save whatever sugar I can. But then again, I'm El Cheapo.)