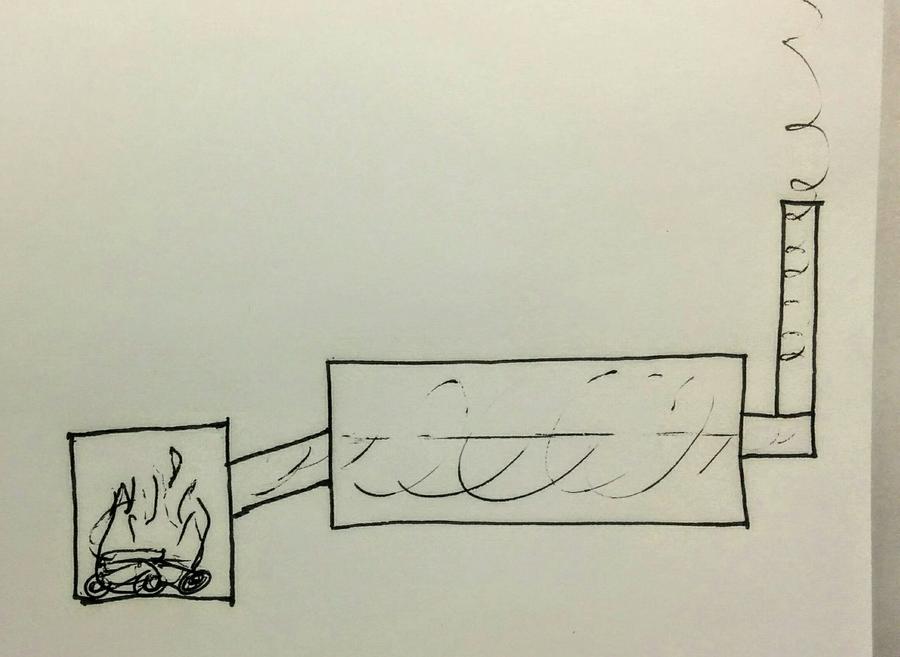

Hi all, I'm planning to build a 20" offset smoker. My design is pretty standard so far, but I wanted to make a change to try to deal with the tendency for temps to get too hot too quick with a good fire going. Maintaining temps between 225 and 250 is usually right on the edge of the flames dying (aka smoldering). So...my logic with the following sketch is that if I place a length of pipe between the firebox and the cooking chamber, I can keep a bigger fire going and the hot air entering the cc will be cooled somewhat on it's way through the pipe. The fb side of the cc will also not get so darn hot due to being right next the raging fire. Just trying to get more even temps without doing a reverse flow. Thoughts?

Firebox connected with additional pipe

- Thread starter randyhood

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

The pipe would have to fairly large, maybe a 6" or so, square tubing may work better something like 4x8? And a shorter distance.

You will loose a lot of heat and it may not be as efficient.

There's a lot of good heat generated from the firebox and when connected it does transfer to the pit which is what I would think is a good thing.

It's better to worry about it getting too hot than to worry about it not getting hot enough

I don't know why you say that 250 is on the edge of smoldering, that sounds like a fire management issue.

If you build with a pipe you may find that in order to keep temps up, you will need a bigger fire, this demanding more air or you will get a dirty burn.

My 2 cents

You will loose a lot of heat and it may not be as efficient.

There's a lot of good heat generated from the firebox and when connected it does transfer to the pit which is what I would think is a good thing.

It's better to worry about it getting too hot than to worry about it not getting hot enough

I don't know why you say that 250 is on the edge of smoldering, that sounds like a fire management issue.

If you build with a pipe you may find that in order to keep temps up, you will need a bigger fire, this demanding more air or you will get a dirty burn.

My 2 cents

Ahumadora, it is actually more of a plenum than a 90 degree elbow. Same as used by Aaron Franklin. It is a pretty solid design improvement from the standard smokestack and is being incorporated by a lot of people. The thought behind it is to get as much air flowing at grate level as possible.

Y'all may be right about the connector pipe, but I'm an inventor and problem solver by nature, so I will always be searching for design improvements, no matter how established they are. As it were, I'm not a big fan of tuning plates. Based on my limited knowledge of convection processes, they improve heat distribution, but worsen airflow (smoke) distribution. What I want is improved heat AND smoke distribution. If you can give me solid scientific reasoning, I will consider abandoning my idea, though ;). Then I'll have to come up with another or begrudgingly follow your advice

Y'all may be right about the connector pipe, but I'm an inventor and problem solver by nature, so I will always be searching for design improvements, no matter how established they are. As it were, I'm not a big fan of tuning plates. Based on my limited knowledge of convection processes, they improve heat distribution, but worsen airflow (smoke) distribution. What I want is improved heat AND smoke distribution. If you can give me solid scientific reasoning, I will consider abandoning my idea, though ;). Then I'll have to come up with another or begrudgingly follow your advice

The current design you have will have the snot knocked out of the heat on a windy day. (But You could insulate the pipe with rockwool)

I always hear folks refer to getting the smoke at smoke level but I feel it doesn't matter unless you have a huge diameter pit. I have experimented with this with no noticeable difference since I built my pit. Yours is the same diameter as mine.

Also about smoke distribution, you may be overthinking that? Due to Diameter.

Improve Heat? nope, not on this design. Like I said, don't know why you would think maintaining 225 - 250 would result in flames dying out and smoldering, this is directly related to Fire Management. Are you basing this on experience or what you are led to believe?

I can run my pit at 225 no problem with hardly any smoke, I can also run it up to 450 degrees but need to make sure all my vents are open, again no problem. I can also run my pit on charcoal.

Your design will work and may be what you are looking for but it will be inefficient, due to heat loss, mainly in windy conditions.

If you are not a fan of tuning plates design a reverse flow (I know in your Original Post you said, you do not want to go the reverse flow route).

No need to abandon your idea and don't hold your breath for scientific explanations, you'll have to research that yourself, there's a ton of builds on this site with charts, tests and calculators. Most folks here are gonna sit back and see how this plays out.

Bottom line is, if you like to tinker, I say go for it and report back, it would be an interesting build.

I always hear folks refer to getting the smoke at smoke level but I feel it doesn't matter unless you have a huge diameter pit. I have experimented with this with no noticeable difference since I built my pit. Yours is the same diameter as mine.

Also about smoke distribution, you may be overthinking that? Due to Diameter.

Improve Heat? nope, not on this design. Like I said, don't know why you would think maintaining 225 - 250 would result in flames dying out and smoldering, this is directly related to Fire Management. Are you basing this on experience or what you are led to believe?

I can run my pit at 225 no problem with hardly any smoke, I can also run it up to 450 degrees but need to make sure all my vents are open, again no problem. I can also run my pit on charcoal.

Your design will work and may be what you are looking for but it will be inefficient, due to heat loss, mainly in windy conditions.

If you are not a fan of tuning plates design a reverse flow (I know in your Original Post you said, you do not want to go the reverse flow route).

No need to abandon your idea and don't hold your breath for scientific explanations, you'll have to research that yourself, there's a ton of builds on this site with charts, tests and calculators. Most folks here are gonna sit back and see how this plays out.

Bottom line is, if you like to tinker, I say go for it and report back, it would be an interesting build.

Last edited:

Thanks for the detailed response, SQUIB.

As far as losing too much heat, that could be a real concern, although being in the Dallas area we don't worry about cold as much as some places. I think I would have a pretty short pipe, and a square one like you suggested.

When I say maintaining 225 to 250 is difficult, I speak from experience, mainly on my COS New Braunfels cooker. Actually, 250 is a pretty good fire, but anything below requires checking the fire very frequently (sometimes every 15 minutes). Basically it would just be easier to have a bigger fire roaring with bigger logs, a bigger critical mass of coal bed, and simply add a good log once every 30 to 60 minutes. Maybe that's unrealistic. I don't care that much about efficiency because I have more oak than I'll probably ever need. And I like big fires.

On airflow/smoke distribution, I realize a lot of my imagination about what happens inside a smoker might be incorrect, but I picture it like water, which I can visualize based on experience. With baffles, water would have a lot of eddies or "stagnant zones" where the water doesn't recirculate nearly as quickly as in a straight, smooth pipe. But perhaps the flow of smoke is way more turbulent than I imagine and it doesn't make any difference, as long as it gets in the chamber. What would be really nice is a glass smoker to see what the smoke really does. Totally ridiculous, I know.

I've got nothing but time for a while before I start the build, so if y'all get sick of my musings, feel free to tell me to shut it.

As far as losing too much heat, that could be a real concern, although being in the Dallas area we don't worry about cold as much as some places. I think I would have a pretty short pipe, and a square one like you suggested.

When I say maintaining 225 to 250 is difficult, I speak from experience, mainly on my COS New Braunfels cooker. Actually, 250 is a pretty good fire, but anything below requires checking the fire very frequently (sometimes every 15 minutes). Basically it would just be easier to have a bigger fire roaring with bigger logs, a bigger critical mass of coal bed, and simply add a good log once every 30 to 60 minutes. Maybe that's unrealistic. I don't care that much about efficiency because I have more oak than I'll probably ever need. And I like big fires.

On airflow/smoke distribution, I realize a lot of my imagination about what happens inside a smoker might be incorrect, but I picture it like water, which I can visualize based on experience. With baffles, water would have a lot of eddies or "stagnant zones" where the water doesn't recirculate nearly as quickly as in a straight, smooth pipe. But perhaps the flow of smoke is way more turbulent than I imagine and it doesn't make any difference, as long as it gets in the chamber. What would be really nice is a glass smoker to see what the smoke really does. Totally ridiculous, I know.

I've got nothing but time for a while before I start the build, so if y'all get sick of my musings, feel free to tell me to shut it.

Randy, Afternoon.... Sounds as if you have air leaks causing your problems... Pictures of your smoker, the doors etc. would help track down the problems....

DaveOmak. I do have some leaks. This is a COS with 1/16" thick steel. For a COS, I think the doors fit pretty tightly, but I do see a little smoke leaking out in a few places. Here are a few photos. These are from before I moved the temp gauge to grate level. You think sealing with gaskets would make a big difference?

Yes it will make a big difference.... Your smoker is a "system".... from firebox to chimney... It needs to be air tight to function properly... The chimney basically is the main "SUCK" point pulling air from the FB and Cook Chamber... Any leaks will interrupt the chimney effect and temp and smoke control will be affected.... Also, for great control, upper and lower air inlets, on the FB, will help with temp control.... Upper air inlet will allow for good air flow through the smoker, while the lower air inlet allows for good control of the fire.... Something similar to the pic below....

Just a follow-up to the issue of sealing up my COS. I completely sealed shut my firebox lid with silicon. Removed smoke-stack, and sealed that connection. Installed fiberglass gasket around the cc door. I think I got pretty close to airtight. I think there is a slight improvement in temp management, but really nothing dramatic or game-changing. I don't think that my leaks were significant enough to have a huge effect on airflow.

gr0uch0

Master of the Pit

I have the old model NBBD, before Charbroil (see: Death Star) turned them into a COS. That said, make sure that you also seal the junction between the FB and the CC: you can lose a lot of heat there as well. To Squib's earlier point, I don't think dropping the FB and connecting the CC with tubing will improve your heat issue, either. If it did, my suspicion is that you'll be going through fuel like water, and unnecessarily so. Baffle, tuning plates, elevate a charcoal basket, and dropping the stack to grate level are all things I've done to mine to regulate the heat. If all else fails, get a welder's blanket to toss over the top is another idea. My $0.02

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 4

- Views

- 718

- Replies

- 2

- Views

- 2K

- Replies

- 12

- Views

- 1K

- Replies

- 5

- Views

- 3K

- Replies

- 3

- Views

- 1K

- Replies

- 15

- Views

- 4K

- Replies

- 0

- Views

- 266

Hot Threads

-

Featured My 2nd ( really first ) Porkstrami , and I must say Glad I did it twice, Only took a little over a month to do.

- Started by DRKsmoking

- Replies: 35

- Pork

-

Man cave!

- Started by Steve H

- Replies: 32

- Blowing Smoke Around the Smoker.

-

Help with a smoked turkey breast?

- Started by DieselTech

- Replies: 30

- Poultry

-

Survey for Daughter's Math Class

- Started by Kvgsqtii

- Replies: 28

- Blowing Smoke Around the Smoker.

-

Pellet Grill Professionals. Couple Questions?

- Started by DieselTech

- Replies: 27

- Pellet Smokers