She saw the one I built for my house a few years back......

copper range hood

- Thread starter kaizerscall

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

bama bbq

Master of the Pit

southernsausage

Meat Mopper

after a few weeks going back and forth the design was decided.........

It would have a bell shape. Basic double roll for the profile. 22x11 top to 42x 22 bottom over a 24" height.

SO I started the fabrication...........

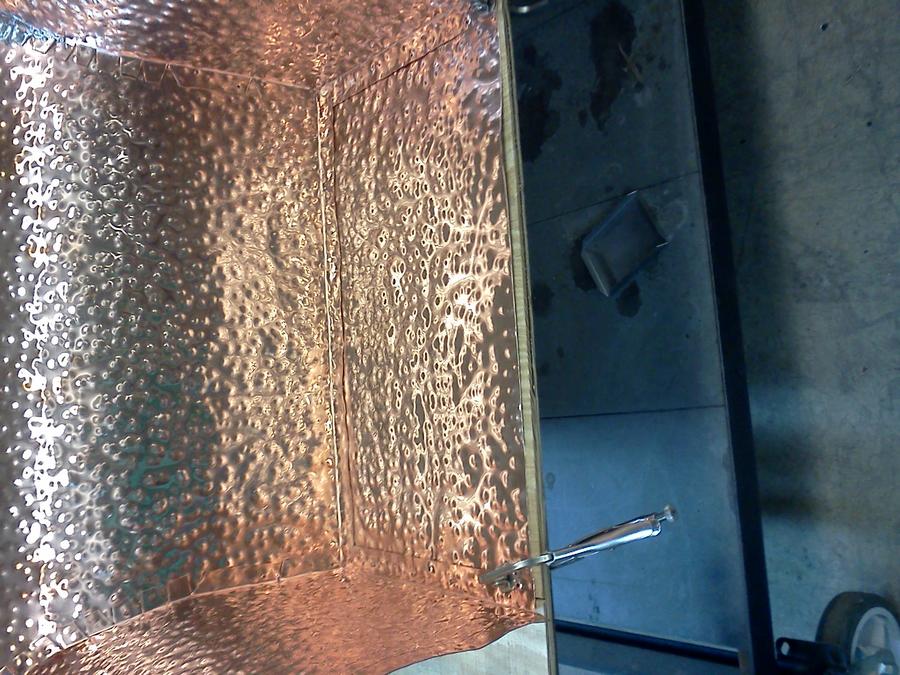

First dimpling the copper.....

Ok..... I made up a box to help with mitering and shaping this thing. ( after making my hood I came up with this idea).

I rolled and shaped the two side pieces and front, Leaving lengths long to work miters. (22 oz copper is not cheap!)

I rolled and shaped the two side pieces and front, Leaving lengths long to work miters. (22 oz copper is not cheap!)

dragons breath

Meat Mopper

Hey KaizersCall you have some forming skills there. I know you have a lot of time in this project. Did you do everything by hand? Great work!

frosty

Master of the Pit

Dragons Breath; Everything is done by hand. The dimpleing was done one hit at a time with a small ball peen hammer. Some places sell hammered sheets of copper, but I like to

give it character! I don't know....... I honestly enjoy working with copper!

give it character! I don't know....... I honestly enjoy working with copper!

smokinhusker

Legendary Pitmaster

Nice job... I know how much work that is, my stepdad does specialty copper and metal work like that.

Thank you for the compliment! Is your step father a Sheetmetal Worker?

Here is the face piece on.

Here is the face piece on.

the left and right shape of the miter ( little by little) then rolling the bar to the bell shape.

Acually worked out well!

Nice! I like the bar, gives it a nice look.

Yeah, my stepdad does specialty sheet metal work, both interior and exterior. He primarily does decorative finish work (counters, range hoods, ect.) but has also done roofs and exterior cladding.

Yeah, my stepdad does specialty sheet metal work, both interior and exterior. He primarily does decorative finish work (counters, range hoods, ect.) but has also done roofs and exterior cladding.

nozzleman

Smoking Fanatic

Does your stepfather have any pictures of work he has done? I love the look that copper brings out in the piece that is made! Its acually an easy metal to work with.

Its easy to shape and reshape. Thanks for the compliments. Has your stepdad seen the hood? whats his thoughts?

Its easy to shape and reshape. Thanks for the compliments. Has your stepdad seen the hood? whats his thoughts?

I soldered the inside seams to add stegnth and also prevent suction loss from the fan assembly( that homeowner purchased).

After recieving the fan assembly, I had to figure out how to fit everything inside hood and keep it operating properly and efficiantly.

I also had to acomplish this while not effecting the finished look to the eye!

I came up with installing the fan in the neck of the hood by means of clips soldered to inside.......

rlefig

Newbie

- Apr 10, 2013

- 1

- 10

Hi, my name is Rob and I live in Reading, MA. I am the single parent of a couple of boys and I am in the process of buying an 1892 house with very tall ceilings and via a short sale and I am looking at a copper range hood. My question to you is do you do this as side work? Is so can you respond to my email address a [email protected]

Thanks, it awesome.

Thanks, it awesome.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 0

- Views

- 316

- Replies

- 0

- Views

- 768

- Replies

- 31

- Views

- 3K

- Replies

- 14

- Views

- 795

- Replies

- 90

- Views

- 8K

Hot Threads

-

Featured It’s the Season!

- Started by civilsmoker

- Replies: 34

- General Discussion

-

Prime Rib Sale

- Started by Gonna Smoke

- Replies: 26

- Beef

-

Crazy Wind - 65-80 Mph tossing semi’s today….

- Started by civilsmoker

- Replies: 24

- Blowing Smoke Around the Smoker.

-

Moving to St. Louis area. Info needed.

- Started by SmokingUPnorth

- Replies: 18

- Blowing Smoke Around the Smoker.

-

Featured 6 racks of St. Louis ribs

- Started by motolife313-2

- Replies: 15

- Pork