Forgive me for having edited this post a few times as I re-read your initial posts and am trying to tailor my answer properly for your application.

Most of the inexpensive consumer-grade temperature measuring systems I've played with use neither RTDs nor Thermocouples. Instead, what seems to be most popular for the typical cooking thermometers are thermistors.

And often these thermistors are quite high resistance. The high resistance is handy because it allows the use of various lengths of wire without worrying too much about the wire's resistance (because it's only a tiny fraction of the resistance of the sensing element itself, and thus, insignificant). It also makes the resistance of the cheesy connectors less of a problem as well. And often they're pretty darn accurate!

But you really need to check and make absolutely sure what sort of temperature sensor is really being used before deciding how to proceed.

If the unit uses a thermistor, it's likely that you can get away with just about anything you want as far as extending the cabling and choosing the connectors.

But it sounds like you may well have a type K thermocouple. Looking at the MYPIN TA4 PID I found on

Amazon, the one I found does indeed use Type K thermocouples!

If that's the case, you may well need to pay attention to how you extend the wiring and how you make up connections. But I'm a fanatic about proper temperature measurement and control, so keep that in mind as you read this!

I spent many years designing data acquisition systems and temperature (and other) control systems. A lot of these were used in laboratories where precise control and measurement for traceable documentation was paramount for regulatory compliance as well as defensibility in court. I designed both the measurement hardware (the electronic circuits) and wrote the software that converted the thermocouple voltages to temperature readings and did the reverse to implement cold junction compensation at the connection points.

My systems used the ITS-90 Type K thermocouple coefficients for calculating the polynomials required. We routinely had thermocouple accuracy in these data acquisition systems of better than 1/10th degree C over a wide range for laboratory ovens. This was verified with NIST-traceable (RTD, by the way) reference thermometers that were certified to be within + or - 0.015 degrees C over the range of -50 to +250 degrees C.

To tell the truth, I was actually amazed at how accurate these thermocouples were over such a wide range of temperatures. For them to be this close, the thermocouples have to be extremely well made using the finest alloys, and the same has to be true of the alloys in the connectors and the extension wire.

All of the TCs and TC extension wire I used over the years was from an outfit called Omega Engineering. Suffice it to say that I was always extremely impressed with how close the TCs, wire, and accessories I got from them performed with respect to the theoretical.

Everything from liquid nitrogen to muffle furnace temperatures worked surprisingly well.

I cannot vouch for thermocouples made by various other manufacturers, but the stuff we got from Omega was always outstanding. And frankly, this amazed me because the way TCs work is somewhat miraculous, and the voltages involved are tiny. It always seemed like there would be a LOT of opportunities for errors!

So anyhow, I do have a lot of thermocouple application and design experience over many years. So hopefully I can be of some assistance. But this may be incredibly boring for most folks. I'm sorry! :)

This is not a trivial subject, but here's a brief explanation of how thermcouples and their measuring systems work, and why it's important to use the proper extension wire, connectors, and configuration.

A thermocouple is a junction between two dissimilar metals. When pressed together, (or often welded together), a voltage is produced that is related to (note, I'm

not saying proportional to) the temperature at this junction.

https://en.wikipedia.org/wiki/Thermoelectric_effect

I haven't read all of that Wikipedia article, but skimming it, it looked good. ;)

The voltage produced is typically very small. I mean REALLY small! For a type K thermocouple, we're talking 39 MILLIONTHS of a volt per degree C. That can be problematic when measuring it because you need to be careful to avoid interference from electrical "noise".

I always used shielded TC extension wire, and tied the shields ONLY at the "receiving" end of the signals. And I used "isolated" style TCs whenever possible. We never had one bit of noise trouble.

Some of the thermocouple probes you get with various PID controllers have their junctions connected to the outer case of the probe. I dislike this! You're just begging for a ground loop. But you take what you get unless you have the ability to order exactly what you want. But that's getting somewhat off topic.

To see what the voltages generated at various thermocouple junction types are for various temperatures, look at this page from NIST:

https://srdata.nist.gov/its90/type_k/0to300.html

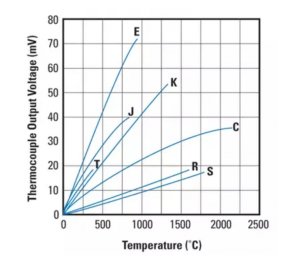

And note that type K thermocouples generate signals (weak as they are) that are higher than those produced by most TC types!

Since you will generate a thermoelectric voltage any place that two dissimilar metals are brought into contact, you need to connect thermocouples carefully to avoid errors created by the "accidental junctions" that you may create along the connection paths.

This is why there are special connectors for TCs as well as special "extension wire". The idea is that other than at the intended measuring junction (the thermocouple probe) and at the "cold junction" at your controller or meter, you want to avoid any connections between dissimilar metals.

So the thermocouple extension wire is made of the same alloys as the thermocouple itself. In the case of Type K, we have one alloy called "Chromel" and another called "Alumel". And in fact, you can use thermocouple extension wire to build your own thermocouples.

All you need to do is take a length of TC extension wire, expose the conductors at both ends, and where you want the TC to be, you weld the wires together to form a thermocouple. If you can't weld them, you can just twist them together tightly for a temporary test TC.

And here's a strange thing: You can solder the two together if you want! In the case of chromel and alumel, you need to scrape them a bit to get through the oxides that may be present, and you have to heat them up quite hot, but they can be soldered using the proper flux.

But why doesn't that give you a bad reading due to the extra, and "incorrect" junctions you've created?

The answer is in "The Law of Intermediate Materials" (or intermediate metals).

The

law of intermediate metals states that the algebraic sum of the thermo-electric voltages in a circuit composed of any number of dissimilar materials is zero if all of the circuit is at a uniform

temperature.

And, since a pair of wires twisted together and soldered is tiny, and all very tightly connected thermally, we can pretty well assume that all of this tiny connection is at the same temperature.

Even if the chromel isn't touching the alumel, but is bridged only by the solder, the effect is as if you only had the two metals of the thermocouple wire present. The other voltages cancel or "zero", and you get a proper chromel-alumel junction, in effect. (This law will be important later.)

The alloys used to make the TC extension wire are usually not as perfect as those used to make the actual thermocouples. So you may not get a guaranteed accuracy when making an "extension wire thermocouple". But they're surprisingly good in my experience. They're plenty good for a lot of purposes.

Where you make connections between the actual thermocouple and the extension wire, there is no dissimilar metal, so no thermoelectric voltage is generated at those "joints".

And if you use the correct connector for the type of thermocouple, the pins and sockets of the connectors are made of the same alloys as the thermocouple and the extension wire. So again, you don't get any thermoelectric voltage generated at these joints.

So ideally, you have the same alloy for each "side" of the thermocouple and all of the wiring and connectors all of the way from the TC probe to the connections on the controller or measuring device.

But what happens when you finally make that connection to the controller? Those screws or terminals will likely be made of something other than the correct thermocouple alloys.

Sure enough, you create (at least) two more thermocouples! Let's say the conductors at the controller are copper. You have a chromel-copper junction on one pole, and an alumel-copper junction at the other pole.

Since each one is making connection to copper, if both terminals are at the same temperature we can still invoke the Law of Intermediate Metals to eliminate the copper junctions from the equation.

But wait! We still effectively have another chromel-alumel juction, right? Yep!

So how do we deal with the voltage generated at the controller end of our wire by this second chromel-alumel junction? We can't eliminate that junction. We do have another temperature measurement point thrown into the mix!

This is important: The voltage you measure at the controller's input terminals is, therefore, a difference. It's the difference between the voltage being generated at the thermocouple probe junction and the voltage being generated at the controller (or meter, or whatever)'s input terminals by the extra junction that we cannot eliminate there.

Again, we see a voltage DIFFERENCE.

This is why, when you look at the tables that the NIST site I linked above generates, you see that the thermocouple voltage is always shown to be zero at zero degrees C. Note that they use this wording at the tops of all of the charts:

"Thermoelectric voltage as a function of temperature (°C); reference junctions at 0 °C".

Note "reference junctions at 0 °C"

They're referring to our "unintentional" or "cold" junctions at the controller end as "reference junctions" here. It's not a magic coincidence that all of the different types of thermocouples magically produce a voltage of zero volts at zero degrees C. The thing to remember is that we're measuring a voltage difference between one of these TC junctions and another TC junction of the same metals.

It's not hard to understand that two TC junctions at the same temperature will both generate the exact same voltage, so the difference between them will be zero regardless of the TC type.

Since thermocouples, in the past, were used almost exclusively to measure very high temperatures, the temperature at the meter or controller terminals was always far cooler than that of the oven, furnace, kiln, etc., that the probe was measuring. It was at "room temperature".

For kiln and burner temperatures, you could pretty well ignore the "room temperature" error that this extra junction created. But the error was there! But if you knew the room's temperature, you could just compensate for that known error in your head, or use a thermometer and deal with it more precisely if you needed to.

I've seen TC "Pyrometers" that are nothing more than a low-current D'arsonval meter movement that you connect to the TC wires. They just print the scale for the meter so that it corrects for an assumed room temperature, and it's usually just fine, especially for kiln type temperatures.

Since the TC system is indicating the difference between the thermocouple probe and the "cold junction" or "reference junctions", we need to add the temperature at the cold junction to our reading to get a more accurate value for the measured temperature.

For more precise measurements, they could run copper wire from the meter's terminals out for a distance, and then make the connections to the chromel and alumel conductors of the TC extension wire. But now, they've just moved the "cold junction" out away from the meter. How can that help?

Here's a trick! They could then cool this junction down with an ice-water bath to be at zero degrees C. And thus, the voltage produced at the "cold junction" was the "zero degrees" TC voltage! Sneaky, but very effective! Now you're effectively only reading the temperature at the measurement junction (the probe) because your "reference junction" is at zero, so the difference in temperature is the true temperature (of course, we're talking about zero degrees C here).

Again, when we look at some of the thermocouple voltage "tables" that you can call up on that NIST page I linked earlier, we see that they all have a thermoelectric voltage of zero volts when the junction is at zero degrees C (with respect to reference junctions which are both at zero degrees C).

And thus, this compensation is known as "cold junction compensation", or sometimes just shortened to CJC.

But what do we do with modern electronics and especially now with microcontrollers at our disposal? Surely nobody wants to be forced to put their cold junctions into an ice water bath!

The answer is that you use something else to measure the temperature of the cold junction. Often, a solid state temperature sensor is mounted on the printed circuit board right near the terminal block where you connect the thermocouple wires. Hopefully, the temperature your semiconductor temperature sensor reads is quite close to the actual temperature at the terminals where the wires connect.

Depending on how this is mechanically designed, it may work very well, or maybe not so well, but this compensation MUST be implemented or you will have an error equal to the temperature at the point where you've made this transition from thermocouple wire to copper (or whatever).

What is often done these days, (and what I did in my hardware and programs) was to measure this semiconductor temperature sensor and thus "know" the temperature at this "cold junction". Then, I did a reverse calculation of the thermocouple polynomials to arrive at the theoretical voltage that this "cold junction" should be producing. I then simply added this "cold junction voltage" to the voltage I measured across the input terminals, and did the polynomial math on that voltage to arrive at what must be the temperature of the "real" thermocouple probe.

There are various ways people do this, including entirely analog methods. But modern systems generally do this just as I did, with a computer program. With these little PID controllers, they already have a microcontroller to do all of the various functions of the controller, so why not just do the TC math with it, too? Writing the code for such a controller only needs to be done once, so it doesn't cost you anything at all to re-use that same code in all of the thousands or millions of these gadgets they produce.

OK, so we have hopefully eliminated all dissimilar metal junctions between the probe and the controller's input terminals, and we've measured the temperature at those terminals, and we've mathematically added this "cold junction error" to our measurement.

But what if we must introduce a junction of dissimilar metals somewhere in the wiring?

You can get away with that as well, if you can reasonably guarantee that the "intermediate metals" are all kept at the same temperature so the voltages generated are cancelled out. And this is often the case because the separate terminals are very close to each other and the individual terminals are thermally connected by the copper of the interconnects themselves.

They make special "isothermal blocks" for such connections. But even a typical barrier strip type terminal block can work fine if you can reasonably expect all of the terminals to be at the same temperature. And usually, they will be. Putting these terminals in an enclosure so they won't be exposed to temperature gradients can help if this is a fairly critical system.

But if you make the transition from thermocouple wire to some other type of wire (as you do at the controller's connectors), you must compensate for the thermoelectric voltage at this "cold junction" (not at the terminals of the controller) or you will have an error that is equal to the difference between the temperature at this junction and at the terminals of the controller or meter.

If I'm understanding correctly, what you're proposing is to extend the connections from the terminals of the PID controller itself out to a connector on the outside of the enclosure in which you're mounting that PID controller.

That way, you don't have to open up your enclosure to make up the TC connections each time you take your controller box out to your smoker.

As

radioguy

radioguy

points out above, you may well be able to get away with doing nothing to compensate for this. Why? Well, if your PID controller, or meter, or whatever is at the same temperature as the point where you make your transition from thermocouple wire to copper wire, then even though your controller is measuring (and compensating for) the temperature at its terminals, since that's at the same temperature as the point where you've made your transition, there is little error.

What I think he's saying is that if you think the point where you're connecting your TC probe's lugs to a pair of terminals on the outside of your enclosure will be "close enough" in temperature to the terminals of the PID controller itself (inside of the enclosure), you could just use "regular" wire to make this short jumper inside of your enclosure, and use a normal barrier strip on the outside of the enclosure to which you can screw your thermocouple's spade lugs to make up that connection each time.

But you will have an error if there is a difference between the temperature "seen" at the PID controller's terminals and the temperature that is at the actual barrier strip on the outside of your enclosure. That might be trivial and unimportant. Or there may be some difference depending on things like heating of the inside of your enclosure caused by the power dissipated by the PID controller itself, or by any SSR or other gadgets that are also inside of, or attached to the main enclosure.

The ideal way to do this would be to get a set of mating type K thermocouple connectors. One would ideally be made to mount through the wall of an enclosure (usually this is the female, and called a "bulkhead connector" or panel mount jack), and the other would be the male (the plug), and would mount taking the place of the crimped-on spade lugs that were provided with your probe.

Since the conductors within the type K connectors will be made using the same alloys as your type K thermocouple, there would be no extra junctions created at these connections. (Note that the connections of these connectors are "coded", and you must connect the correct wire to its assigned "pin" in the connector). They're marked, though, as + and -.

And ideally, you'd then use a short piece of type K thermocouple extension wire to connect from this special connector (mounted through the enclosure) to the terminals on the PID controller itself.

Thus, you could simply plug your type K thermocouple into your PID box when you take it out to run your smoker, and then unplug it when you bring the controller back inside.

Further, because you now have a standard female type K connector on the outside of your controller, you can buy or build more type K thermocouple probes and plug them into the controller for other uses if you want.

So it comes down to how much temperature difference you think you may have between the terminals of your PID controller (where presumably, they're measuring and compensating for the "cold junction" temperature) and the new point, outside of your box, where the actual "cold junction" will be.

Since your thermocouple will be attached to your smoker, you'll want to protect the connector or lugs and really, the whole TC wire when you're storing the smoker. I'd keep all of that from getting wet or being exposed to weather when the smoker is not in use. But that shouldn't be too hard.

People on this forum are often complaining about differences in temperature that they're reading between several different probes within their smoker, or between what a smoker's temperature control reads versus what their external thermometer(s) read, etc.

So the error you may introduce by NOT using thermocouple extension wire and proper connections in the whole circuit might be enough to later cause you some heartburn. My point is that if you're going to the trouble to use a separate PID controller to control the temperature of your smoker, you may also be something of a temperature control fanatic. ;)

And if that's the case, you do need to be aware of the potential errors and uncertainties you will introduce if you don't do it all "right".

You can often find thermocouple extension wire on EBAY in partially-used rolls, and sometimes find the special connectors there, too. For excellent thermocouples, wire, and accessories, there's always Omega Engineering.

Their website also has a lot of good information about the theory and application of thermocouples.

If you just need a small amount of TC extension wire, I have a lot of it laying around. So I could just send you a little bit. But what I'd also want, for a setup like yours, is a mating pair of type K thermocouple connectors to use where you'll be making up the connection to your smoker over and over.

I'm not sure if I have any of those around, but again, EBAY is often our friend for this kind of stuff!