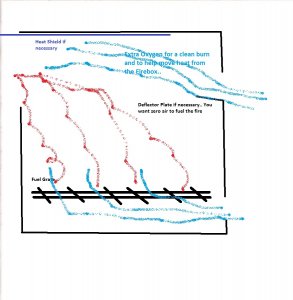

Just got an Oklahoma Joe's Longhorn 3-1. Side firebox with smoke chamber. I've already taken steps to seal up gaps, cracks, seams. I ran one test burn so far, concerned about air movement. I checked the Feldon calculator for air inlet and exhaust sizes, and it is clear that the firebox is way too big (round 19" x 17"). It has 230% larger volume than recommended for the cook chamber (cook chamber is round 20" dia x 20" long). Also the fresh air damper and exhaust are too small. Exhaust is 3" dia x 7" long, calc says it should be 34" long. Fresh air inlet is approximately 50% too small.

I'm considering purchasing a Lavalock automatic blower system - I'm wondering if having the forced air in will compensate for these volume shortfalls?

I'm considering purchasing a Lavalock automatic blower system - I'm wondering if having the forced air in will compensate for these volume shortfalls?