~~its been a while

I was still reading along but a lot has changed ( rebuilding the house getting a son into the world ...)

so now i'm back and hoping to create a smoker at last

a lot of the old materials I had were delivered to the scrapyard ($$$) and some new ones are bought, first a new trailer from an old caravan +/- 7 meters (gne reduce that to 4 meter max.) a 250 gal propane tank, 2 gas burners...

the rig will be made in a school where they teach metal crafting, welding, car mechanics so I think the welding and stuff will be oke (I hope so)

I still have a lot of questions so here we go:

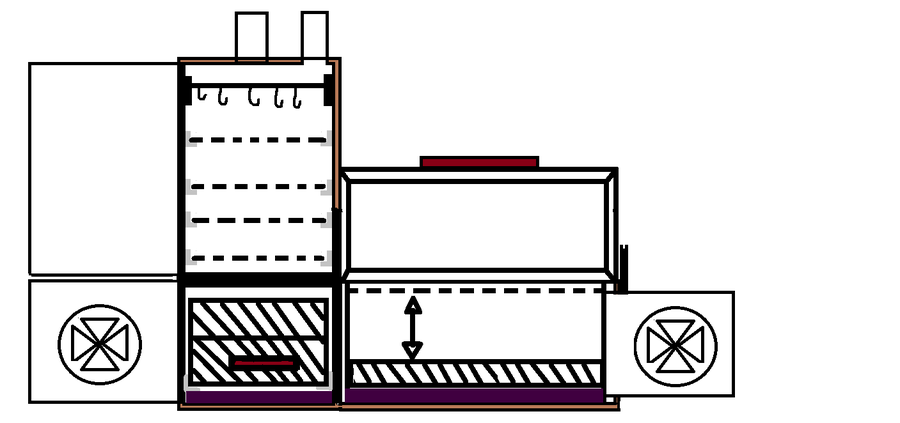

1. for the fb I have a 1/4 inch plate is that thick enough?

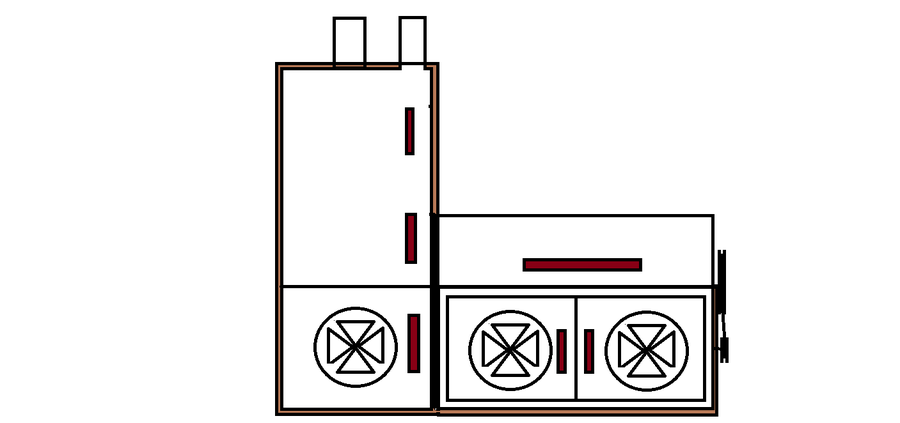

2. i'm going to place a food warmer on top of the fb do I need to leave some space between them?

3. is I isolate the fb and the warmer how thick does the outer iron need te be?

4. should I isolate the bottom of my cc to?

5. what type isolation I use best?

6. how thick does the rf plate needs to be?

7. when I cut off the end of the tank should I measure from the cut point to the front to calculate my fd dimensions?

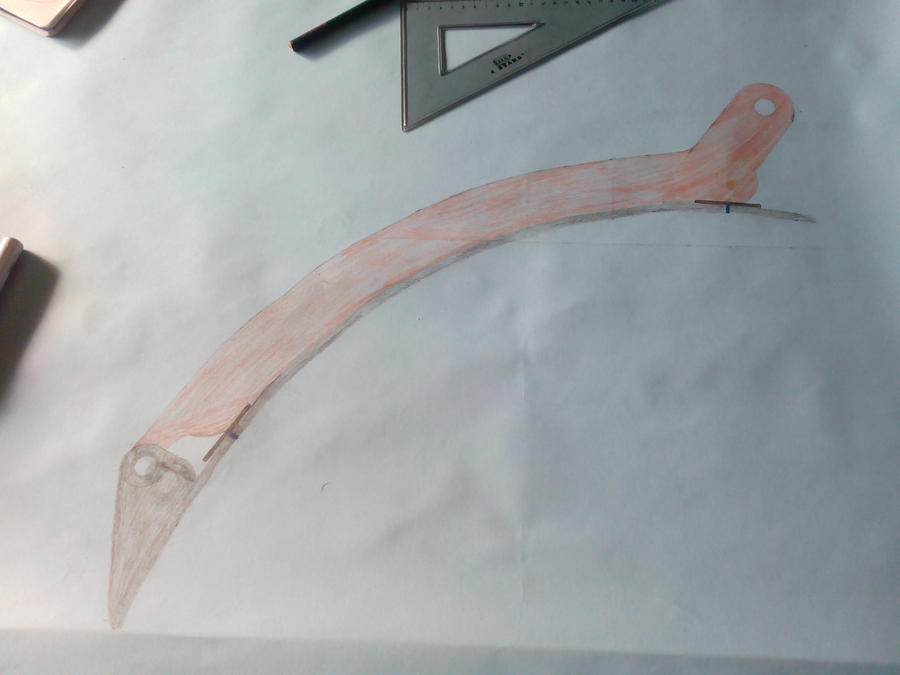

7. can I use tis iron to make a charcoal/wood basket? and how thick should I take?

I'm planning to go scrapyard hunting next weekend

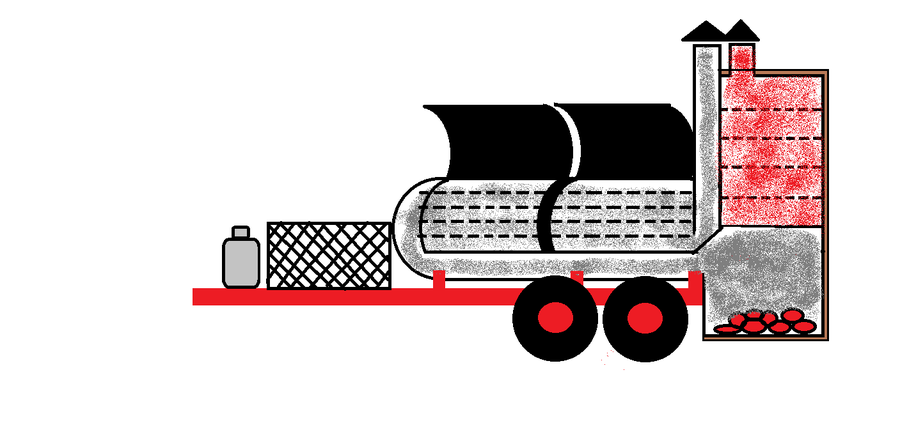

here are some plans on what I want to create

I was still reading along but a lot has changed ( rebuilding the house getting a son into the world ...)

so now i'm back and hoping to create a smoker at last

a lot of the old materials I had were delivered to the scrapyard ($$$) and some new ones are bought, first a new trailer from an old caravan +/- 7 meters (gne reduce that to 4 meter max.) a 250 gal propane tank, 2 gas burners...

the rig will be made in a school where they teach metal crafting, welding, car mechanics so I think the welding and stuff will be oke (I hope so)

I still have a lot of questions so here we go:

1. for the fb I have a 1/4 inch plate is that thick enough?

2. i'm going to place a food warmer on top of the fb do I need to leave some space between them?

3. is I isolate the fb and the warmer how thick does the outer iron need te be?

4. should I isolate the bottom of my cc to?

5. what type isolation I use best?

6. how thick does the rf plate needs to be?

7. when I cut off the end of the tank should I measure from the cut point to the front to calculate my fd dimensions?

7. can I use tis iron to make a charcoal/wood basket? and how thick should I take?

I'm planning to go scrapyard hunting next weekend

here are some plans on what I want to create

Last edited: