I apologize for the length lol there was alot of work that happened to this smoker.

So I decided to build my own smoker. I have an electric vertical smoker I use frequently and I like the racking system and the door. So I decided vertical would be the way to go. I was going to do an offset box originally then I spoke to my uncle and he mentioned reverse flow. So I did some googling (came across this forum) and I liked the idea of that.

I have searched and searched for something like the smoker I envisioned and found one sorta like it... but not quite. So I hoping this will provide some insight to someone like me in the future, or maybe there is a reason you cant find a smoker like this and I wasted some time and money lol (I will soon find out).

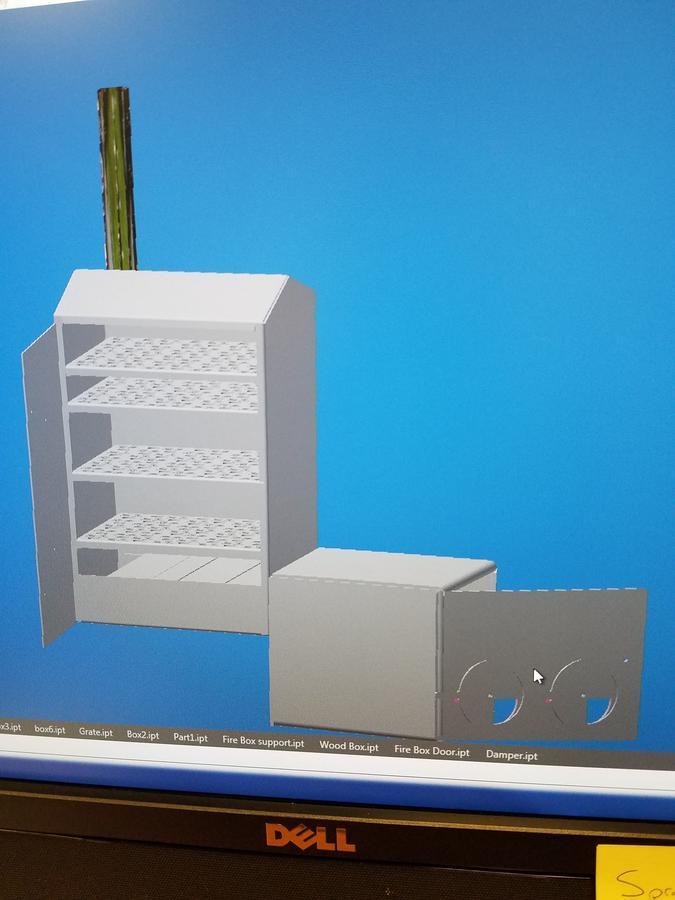

So after tinkering around in 3d CAD, I decided I wanted the build (with the exception of the firebox) to fit onto 1 4'x 8' sheet of 1/8in metal. We have a CNC plasma cutter that takes 4x 8 sheets and running a program and cutting it all at once seems practical. Originally I was going to use 3/16 metal for everything but the weight and building at home made it impractical.

So for the design, the cooking chamber is going to be 30 tall x 19 deep x 24 wide with two doors. this unit will takes 3 standard oven racks 18x24 for the meat to set on.

As for the firebox, I had some 3/16 plate and fabricated the large smoke box below. (18x18x24). After I found calculations for it, it is over sized but I can deal with that vs being too small.

So once I began building I asked my daughter about a name for the smoker, after she provided several options we decided to name the Smoker MEEF (Meat + Beef)

So after cutting out the plates and a ton of cleaning the fun began with fabrication the cooking chamber.

(If i did this again would put in the angle iron for the racks on the sides prior to tacking sides together. The sides will distort after welding and clamping the angle in the back is impossible)

I decided to use the reverse flow plate also as a grease drain which i will plumb a ball vale on into the future.

So the rest was welding the corners few hours of work there.... then the front was added

and a grease rail to lead to the drain pipe and the rails for the oven racks and the dual exhaust.

Now this is the part that I was unable to find a lot of information on. all i found was the chimney can be significantly shorter. The vertical cooking chamber will "act as part of the chimney" so my adjustable vent pipes are short like 6 inch in length each. Any insight on length or where to find information would be great and appreciated. All i was

Now the fun began attack the 130lb firebox to the 150 cooking chamber... took some strength was able to do it... then setting it on the ground was the real fun part. (it has to be upside down i built a stand for it that way so i can add legs and wheels on later this week)

So that is the progress I have made so far. A few hours here and there add up over the last two weeks. I am hoping to do legs and wheels this week then the last thing will be the doors. Then on to paint.

I will update the post as I continue working on this project. But in the mean time let me know your thoughts or comments.

Thanks,

Matt

So I decided to build my own smoker. I have an electric vertical smoker I use frequently and I like the racking system and the door. So I decided vertical would be the way to go. I was going to do an offset box originally then I spoke to my uncle and he mentioned reverse flow. So I did some googling (came across this forum) and I liked the idea of that.

I have searched and searched for something like the smoker I envisioned and found one sorta like it... but not quite. So I hoping this will provide some insight to someone like me in the future, or maybe there is a reason you cant find a smoker like this and I wasted some time and money lol (I will soon find out).

So after tinkering around in 3d CAD, I decided I wanted the build (with the exception of the firebox) to fit onto 1 4'x 8' sheet of 1/8in metal. We have a CNC plasma cutter that takes 4x 8 sheets and running a program and cutting it all at once seems practical. Originally I was going to use 3/16 metal for everything but the weight and building at home made it impractical.

So for the design, the cooking chamber is going to be 30 tall x 19 deep x 24 wide with two doors. this unit will takes 3 standard oven racks 18x24 for the meat to set on.

As for the firebox, I had some 3/16 plate and fabricated the large smoke box below. (18x18x24). After I found calculations for it, it is over sized but I can deal with that vs being too small.

So once I began building I asked my daughter about a name for the smoker, after she provided several options we decided to name the Smoker MEEF (Meat + Beef)

So after cutting out the plates and a ton of cleaning the fun began with fabrication the cooking chamber.

(If i did this again would put in the angle iron for the racks on the sides prior to tacking sides together. The sides will distort after welding and clamping the angle in the back is impossible)

I decided to use the reverse flow plate also as a grease drain which i will plumb a ball vale on into the future.

So the rest was welding the corners few hours of work there.... then the front was added

and a grease rail to lead to the drain pipe and the rails for the oven racks and the dual exhaust.

Now this is the part that I was unable to find a lot of information on. all i found was the chimney can be significantly shorter. The vertical cooking chamber will "act as part of the chimney" so my adjustable vent pipes are short like 6 inch in length each. Any insight on length or where to find information would be great and appreciated. All i was

Now the fun began attack the 130lb firebox to the 150 cooking chamber... took some strength was able to do it... then setting it on the ground was the real fun part. (it has to be upside down i built a stand for it that way so i can add legs and wheels on later this week)

So that is the progress I have made so far. A few hours here and there add up over the last two weeks. I am hoping to do legs and wheels this week then the last thing will be the doors. Then on to paint.

I will update the post as I continue working on this project. But in the mean time let me know your thoughts or comments.

Thanks,

Matt