I built a quick RF smoker out of scrap I had laying around last year. It is a 80 gal compressor tank with a 1/4" fire box and RF plate. I used the Feldon calculator for all the sizes and openings. I still have a 70* temp difference from side to side, with the FB side being the hotter. Will a deflector plate underneath the RF plate on the FB side help this? I am cooking for my premed 50th anniversary party next week, and would like to fix it before hand. Thanks in advance.

Side to side temp help

- Thread starter gbmworks

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMF is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Do you have a pic of the smoker?

Perhaps you have a leak under the RF plate at the firebox? Just guessing here, I just got my RF built and only have a few burns under my belt, but I have a upper / lower temp difference which I think is due to air sneaking in under my door..

Perhaps you have a leak under the RF plate at the firebox? Just guessing here, I just got my RF built and only have a few burns under my belt, but I have a upper / lower temp difference which I think is due to air sneaking in under my door..

Nothing fancy, just a standard RF. I fully welded the RF plate in and made sure it was water tight. I made it so that I could use the RF plate as a water pan if I wanted.

I put a deflector plate in this morning, with no change to the temps.

If someone has any other suggestions, I would REALLY appreciate it. I don't want to have 80 people disappointed with bad BBQ.

Sent from my iPhone using Tapatalk

Going off the pic, it looks like your firebox needs to be higher up into the chamber (and your RF plate as well). I'm wondering if there isn't enough airflow to maintain even temps. Your air is rapidly cooling on the left side and the right side is being heated by conduction through the metal. I'de lose that rain shield at the top too.. let that smoke go.

Other than that, thats a cool smoker..

There are more RF experts on here, hopefully one will chime in..

Other than that, thats a cool smoker..

There are more RF experts on here, hopefully one will chime in..

Looking at what I can see, your RF plate is not high enough up from the bottom of the Cook Chamber... May also be too close to the end of the smoker.... As Pit 4 brains noted, your FB is too low.....

Feldon's has problems when building a RF smoker.... Look at this tutorial.... it explains some of the problems and how to get uniform temps...

http://www.smokingmeatforums.com/a/reverse-flow-smoker-how-to-calculate-build-tutorial

Does your FB have air inlets like these....

..........

Feldon's has problems when building a RF smoker.... Look at this tutorial.... it explains some of the problems and how to get uniform temps...

http://www.smokingmeatforums.com/a/reverse-flow-smoker-how-to-calculate-build-tutorial

Does your FB have air inlets like these....

..........

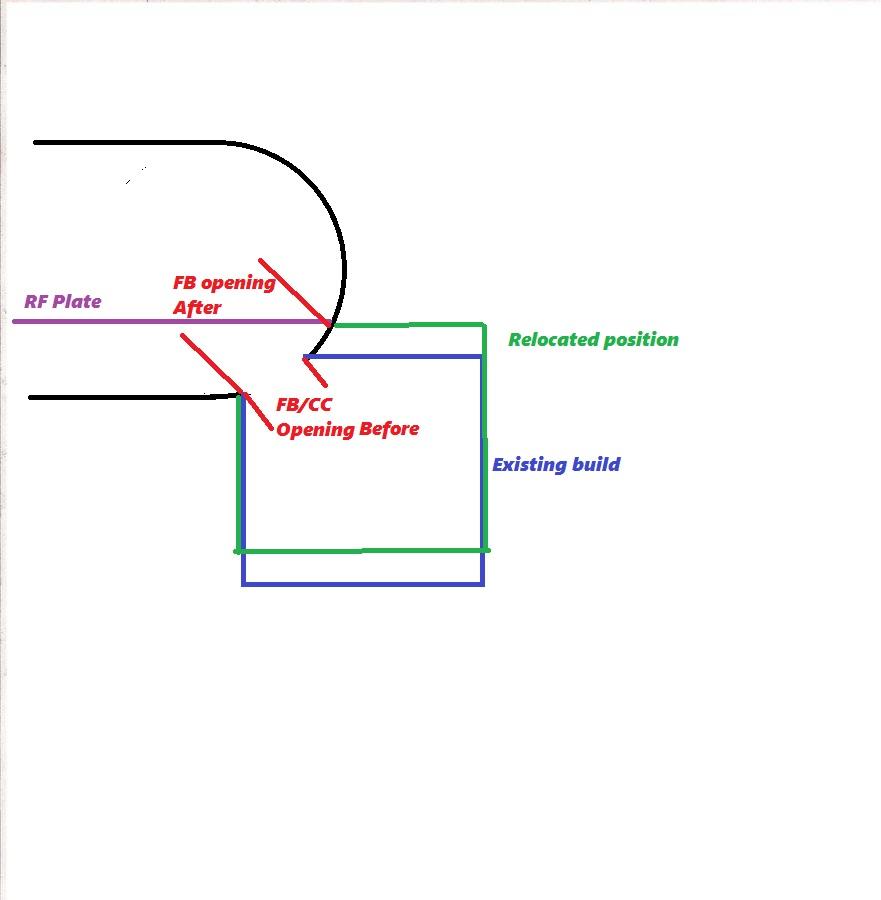

Pit 4 brains and DaveOmak, these are my air intakes. The RF plate is actually 4" up from the top of the FB. Should I raise the FB up. So that the top of it is even with the RF plate?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Well that depends,

Is your firebox only cut on the side or is it cut on top to fit the contour of the tank?

I'm thinking if its only cut on the side, then it could stand to go up and you would just have to cut a bigger smile out of the firebox.

Or maybe you can cut some out of the top of the firebox to match the shape of the tank thus allowing more air to get out.

Not sure which one would be easier.

How close to the end does your RF plate run?

Bottom line is all your dimensions should agree with this calculator..

Standard Reverse Flow Smoker Calculator... by DaveOmak and others... Ready to use.. rev5.....

If you note in the calculator, the firebox to cooking chamber (fb/cc) opening should be the same size as the area under the RF plate and the same size as the opening at the end of the plate.

The area of the cross section of space under the RF plate is a product of the size of the cc. you may need some serious adjusting.

A thin door seal wouldn't hurt either..

Is your firebox only cut on the side or is it cut on top to fit the contour of the tank?

I'm thinking if its only cut on the side, then it could stand to go up and you would just have to cut a bigger smile out of the firebox.

Or maybe you can cut some out of the top of the firebox to match the shape of the tank thus allowing more air to get out.

Not sure which one would be easier.

How close to the end does your RF plate run?

Bottom line is all your dimensions should agree with this calculator..

Standard Reverse Flow Smoker Calculator... by DaveOmak and others... Ready to use.. rev5.....

If you note in the calculator, the firebox to cooking chamber (fb/cc) opening should be the same size as the area under the RF plate and the same size as the opening at the end of the plate.

The area of the cross section of space under the RF plate is a product of the size of the cc. you may need some serious adjusting.

A thin door seal wouldn't hurt either..

Last edited:

I'm thinking using a compass, scribe a line just below the RF plate.... Using a cut off wheel, cut out the CC and raise the FB.... That would be the fastest, easiest and look the best..

Check to see your current build fall in line with the numbers from the tutorial....

Not much point in doing the work unless you can make it the best smoker you can now.... That includes the exhaust stack....

If you have to or want to move the RF plate, cut it out.... weld in angle iron to the new location and set the old RF plate on the angle... AND move the CC up to the new RF plate height....

Check to see your current build fall in line with the numbers from the tutorial....

Not much point in doing the work unless you can make it the best smoker you can now.... That includes the exhaust stack....

If you have to or want to move the RF plate, cut it out.... weld in angle iron to the new location and set the old RF plate on the angle... AND move the CC up to the new RF plate height....

Thanks guys. I took the ol hot wrench to it and will hopefully have the fire box in its new location tonight. I'll throw a fire in it tomorrow after work and see how the temps are. I really appreciate the help!!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I'm guessing you are serious ??? that didn't take long.....

Will you be able to butt the FB up to the RF plate ??

Will you be able to butt the FB up to the RF plate ??

Last edited:

Hot wrench..LOL

I always called it the Mighty Blue Knife when I used it for demo..

Looks like you're opening it up quite a bit.. That will improve things for sure.

What is the I.D. of your stack?

I always called it the Mighty Blue Knife when I used it for demo..

Looks like you're opening it up quite a bit.. That will improve things for sure.

What is the I.D. of your stack?

sparktexas

Newbie

I had the same issue on my smoker that I converted to a reverse flow. I had about 45 degrees difference from end to end with firebox side hotter. I fixed the problem by making the hole at the end of the plate smaller. Just put a piece of plate at the end that you can slide side to side to find the right opening size

I was thinking that while your smoker is in dry dock, maybe you could add an extra rack in there. Looking at your pics, I see your door goes well over top dead center.. Not good. I don't see a way to fix that other than to seal that door all the way around.

bigeee

Newbie

Hi GBMworks,

I have a silly question, did you determine the temps at your cook racks using the two gauges alone ??? it may be just not so accurate gauges.

I had the same problem with my build, three gauges in the cook area and one in the stack. All were way different. All brand new and zero'ed

I took my two Maverek ET733's and set both to BBQ settings and clipped the four probes to the cook racks and all spots were only a few degree's different.

I rely solely on my wireless temp set ups and consider the gauges as ornamental.

I have a silly question, did you determine the temps at your cook racks using the two gauges alone ??? it may be just not so accurate gauges.

I had the same problem with my build, three gauges in the cook area and one in the stack. All were way different. All brand new and zero'ed

I took my two Maverek ET733's and set both to BBQ settings and clipped the four probes to the cook racks and all spots were only a few degree's different.

I rely solely on my wireless temp set ups and consider the gauges as ornamental.

Welp..... I got home today and threw a fire in the smoker. I let it burn for an hour or two before checking the temps. Yup, 70* temp difference still. I switched the gauges side to side and still had a 70* difference. Except opposite sides!!! Yup, I'm thinking BIGEEE was right with the bad gauges. It definitely heats up faster with the firebox raised. I'm going to order some decent temp gauges and see what the temps really are. Thanks again for all the help and suggestions.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

It sure looks like it's going to get way better airflow now. Once you get some good thermos in there, that's going to be smoking" machine!

Well, one thing I found out is............... you are NOT a procrastinator !!!!!!

Grass don't grow under your feet !!!!!

Holey Krap, you are a GET 'R DONE guy.....

Grass don't grow under your feet !!!!!

Holey Krap, you are a GET 'R DONE guy.....

My new gauges didn't come in yet, so I'm going to run and grab some digital probes from a local store for now. Other than that, I'm all set up and ready to wake up early and watch a fire for hours.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I like that little gazeebo and your smoking area.. You could stuff that smoker right under there in case of rain..

Luckily it's going to be 90 and sunny all day. Put the digital temp probes in the smoker this morning. I can't complain about this temp difference. This is just from when the smoker was warming up.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 17

- Views

- 1K

- Replies

- 3

- Views

- 1K

- Replies

- 15

- Views

- 4K

- Replies

- 16

- Views

- 2K

Hot Threads

-

Spammer PMs, Anybody Else?

- Started by chilerelleno

- Replies: 66

- Blowing Smoke Around the Smoker.

-

On the Edge of Trying Sausage Making

- Started by BrianGSDTexoma

- Replies: 35

- Sausage

-

Took a stroll this afternoon

- Started by Buckeyedude

- Replies: 33

- Field and Stream

-

Featured Blackened Rockfish...

- Started by Gonna Smoke

- Replies: 33

- Fish

-

Colombian Chorizo

- Started by SmokinEdge

- Replies: 32

- Sausage