Hi SMFs!

I've spent the last week or so reading through as many posts here on the forum as I could find. I am at a crossroads in designing my build, and would like to come to the hive mind for help.

I followed daveomak

's calculator to a T, and came up with what I think is a really neat design. However, after watching YouTube videos until I cannot see straight anymore, I am having a dilemma with my firebox door design.

daveomak

's calculator to a T, and came up with what I think is a really neat design. However, after watching YouTube videos until I cannot see straight anymore, I am having a dilemma with my firebox door design.

Many of the "top" builders have a very basic firebox design - solid door with latch to set opening and build a bed of coals on the bottom of the firebox.

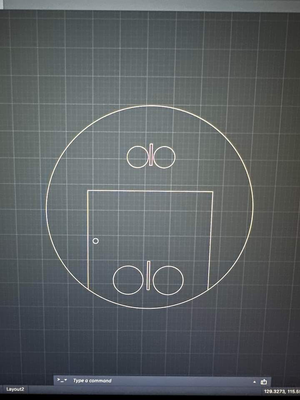

Following the advice of the calculator, I've got my air inlets at just over the recommended opening size (pic attached) with ~80% at the bottom and 20~ at the top (directly across from my cc/fb opening).

Which is the better design and why? Also, is it the consensus to build your coals directly on the base of the FB, or raise the fire in a basket/nest and allow your bottom air inlets to directly feed the fire?

I've spent the last week or so reading through as many posts here on the forum as I could find. I am at a crossroads in designing my build, and would like to come to the hive mind for help.

I followed

Many of the "top" builders have a very basic firebox design - solid door with latch to set opening and build a bed of coals on the bottom of the firebox.

Following the advice of the calculator, I've got my air inlets at just over the recommended opening size (pic attached) with ~80% at the bottom and 20~ at the top (directly across from my cc/fb opening).

Which is the better design and why? Also, is it the consensus to build your coals directly on the base of the FB, or raise the fire in a basket/nest and allow your bottom air inlets to directly feed the fire?