- May 14, 2016

- 35

- 12

Hi folks,

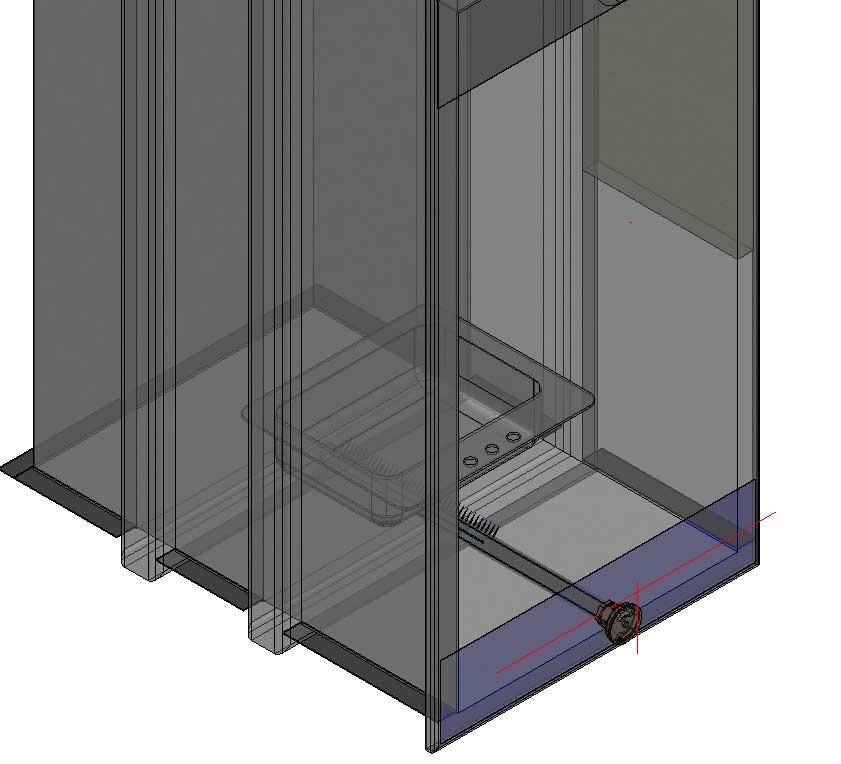

I'm building a large vertical gas smoker.. Its 7 feet tall, 4 feet deep and 3 feet wide.

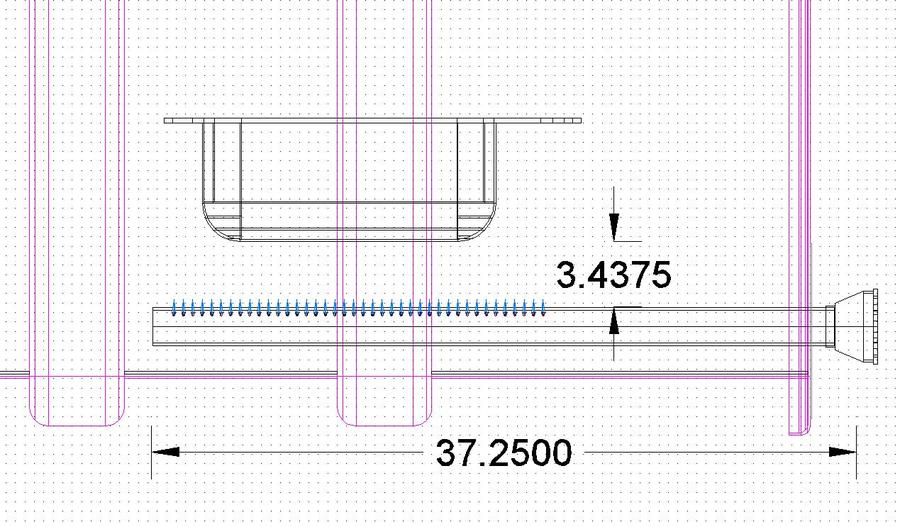

I'm using a straight pipe burner I've calculated to produce about 30,000 btu's at full throttle..

My smoker is well insulated and built out of 11ga 316 stainless steel, then insulated with 2 inch of mineral wool insulation and covered in steel barn siding.

My wood chip pan is a stainless steel sink that is about 16 inches x 20 inches x 6 inches deep. I made a plate to cover the drain hole.

My questions:

What's with all the sawdust I'm seeing? Should I be planing on using saw dust instead of larger wood chips?

My most important question: How far above the pipe burner flames should my wood pan be? Being its a stainless steel sink, I didn't see any harm in letting the flames touch the sink. Or is that bad?

I've seen a lot of folks making wood pans out of a screen material.. Is that important for some reason? Maybe something to do with the ashes falling away?

Thanks!

I'm building a large vertical gas smoker.. Its 7 feet tall, 4 feet deep and 3 feet wide.

I'm using a straight pipe burner I've calculated to produce about 30,000 btu's at full throttle..

My smoker is well insulated and built out of 11ga 316 stainless steel, then insulated with 2 inch of mineral wool insulation and covered in steel barn siding.

My wood chip pan is a stainless steel sink that is about 16 inches x 20 inches x 6 inches deep. I made a plate to cover the drain hole.

My questions:

What's with all the sawdust I'm seeing? Should I be planing on using saw dust instead of larger wood chips?

My most important question: How far above the pipe burner flames should my wood pan be? Being its a stainless steel sink, I didn't see any harm in letting the flames touch the sink. Or is that bad?

I've seen a lot of folks making wood pans out of a screen material.. Is that important for some reason? Maybe something to do with the ashes falling away?

Thanks!