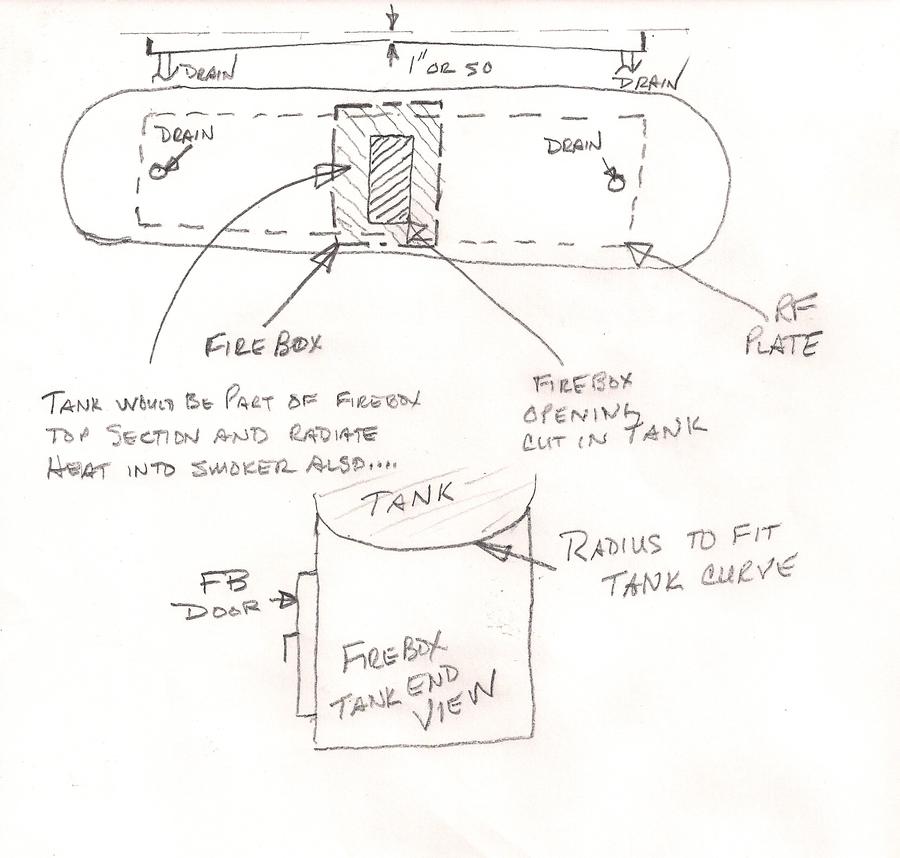

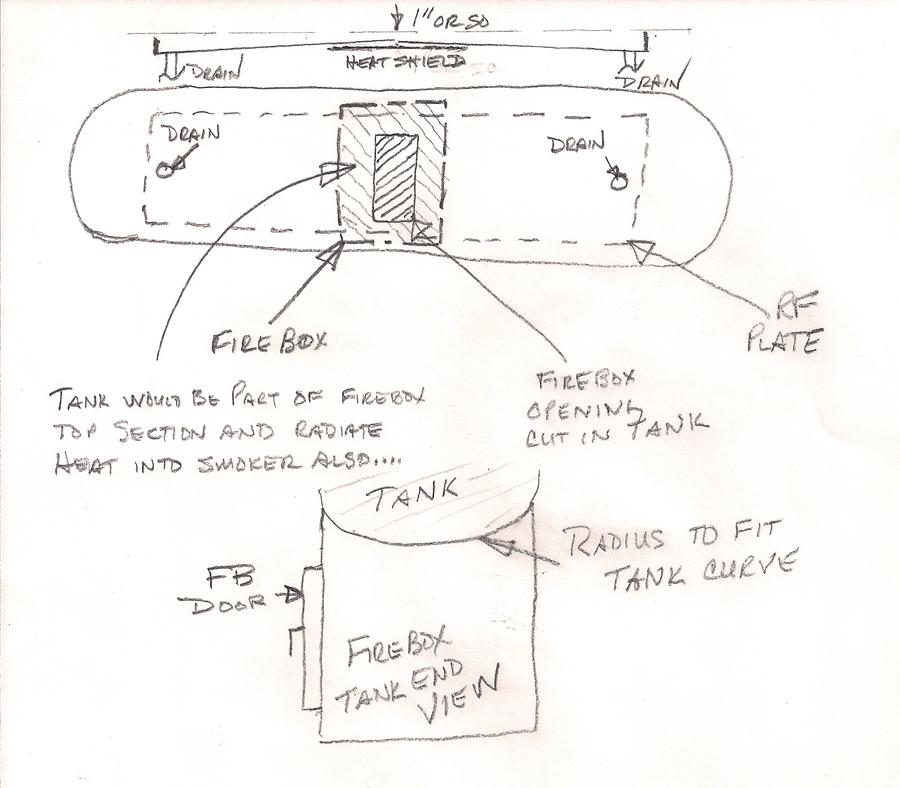

Mark, evening... Are you planning on insetting the firebox into the tank or contouring the firebox to fit the circumference of the tank ???

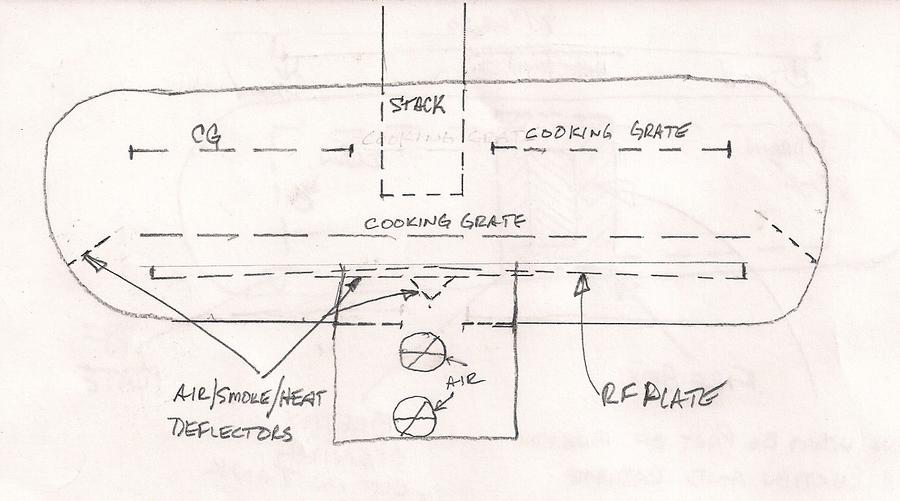

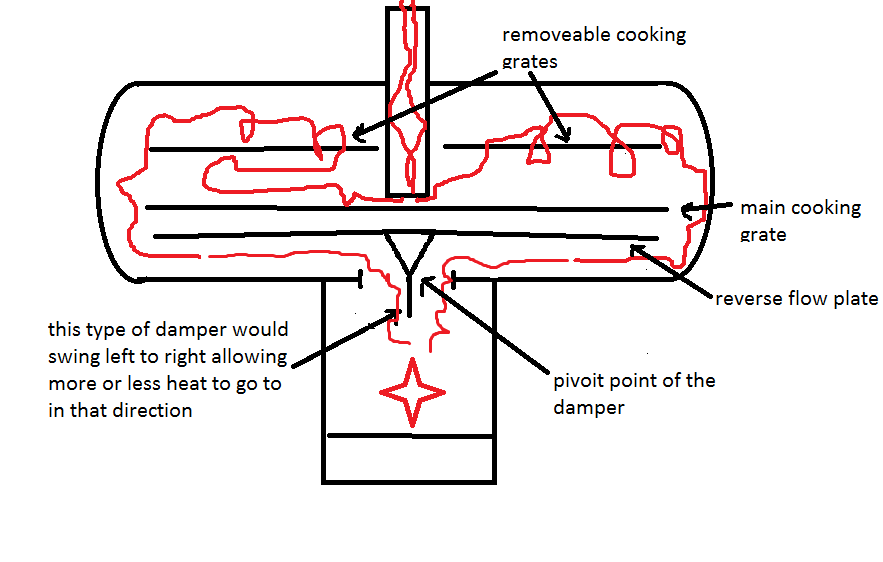

I'm thinking, contour the firebox to the tank..... Cut a slot for the firebox opening..... cut it on the curve portion of the tank.... Not long ways but short direction... cut the opening what ever the calculator says the firebox opening should be.... when figuring the dimensions of the FB opening, make the length just shorter than the width of the RF plate..... That way, heat leaving the FB would be the width, more or less, of the RF plate and the entire plate would get heat...as the heat and smoke traveled toward both ends of the smoker....

Hope all that makes sense... Never thought about a smoker built like this one before.... trying to think outside the box....

I get the idea of the box being cut to fit the tank but was wondering if the heat that is hitting the curved part of the tank will be forced towarde thge outside of the RF plate. If that makes sense?

click on pics to enlarge

With this configuration, you might install a plate, above the firebox, with a 1/16" gap under the RF plate to reduce the direct heat from the firebox on the RF plate.... Just trying to think ahead..... Maybe suspend it from 1 center bolt to allow for expansion and contraction.... with the center of the RF plate higher than the rest, it should self support and leave a gap.... I would use at least a 1/2" bolt.... that point is going to get a lot of heat.... It could be reached from inside the firebox if need be... and use a think chunk of steel because of heat erosion on it.... it will be a b*tch to replace.....

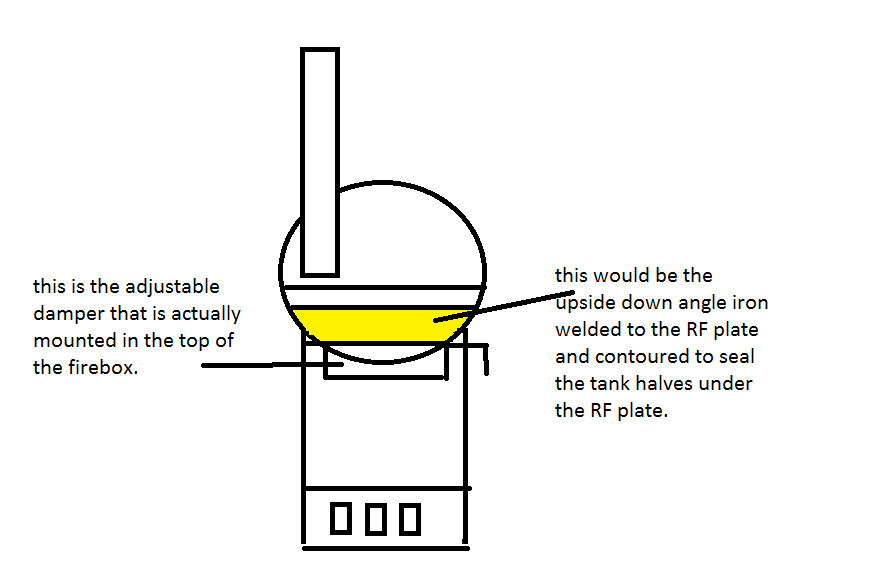

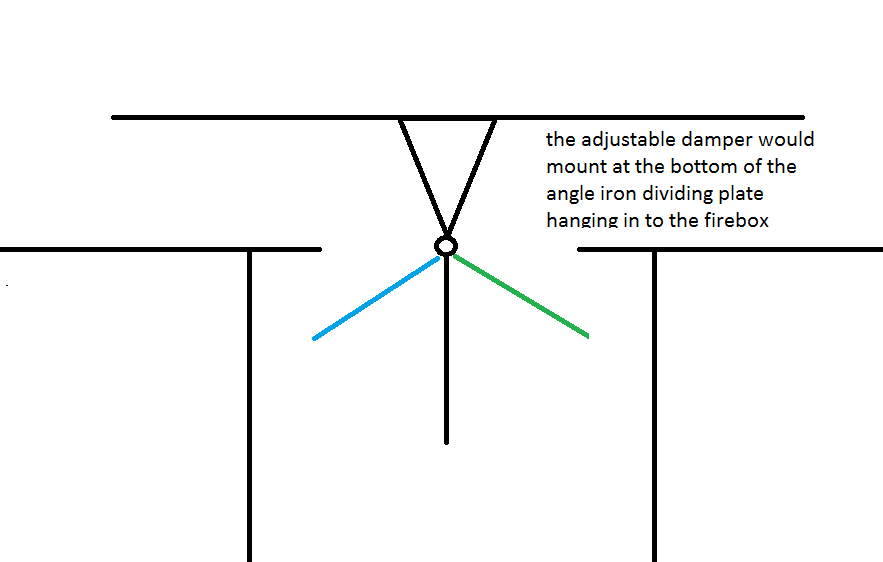

i do like this idea! but wouldnt it be better to make the firebox with a top and cut a hole in it with a damnper to control which side gets more heat

View media item 178663

Dave