I purchased a Raspberry Pi and received it about a week ago. If you're not familiar with the Raspberry Pi, it is basically a full blow Linux computer and about the size of a credit card. I've added an ADC IC to the board and gave it the capability to monitor up to 10 temperature sensors. I have a thermocouple for detecting flame as well, but I haven't implemented that feature yet.

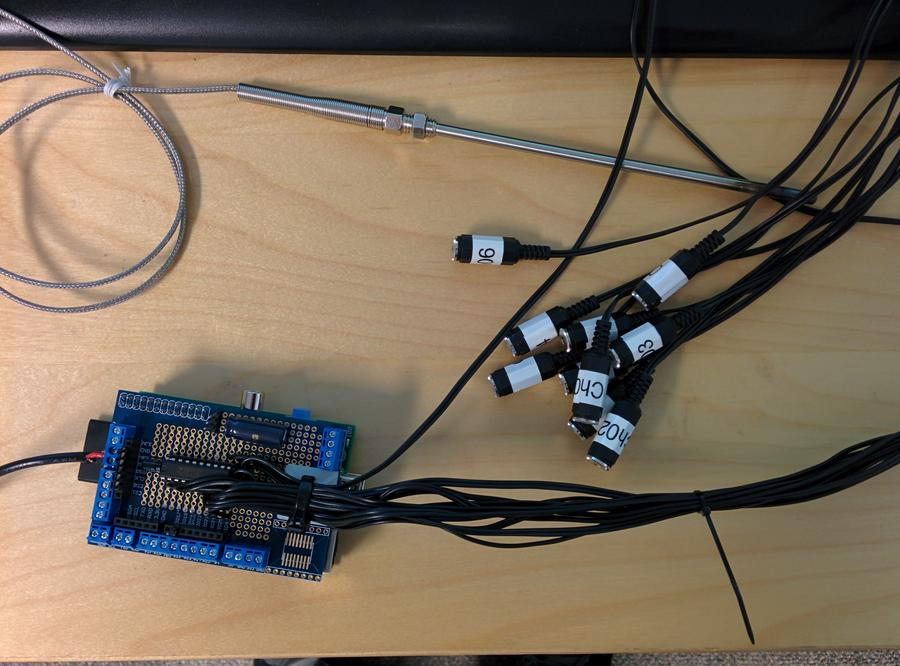

What you see below is the add-on board with the analog to digital converter. The cables coming off of it allow for connecting to temperature probes.

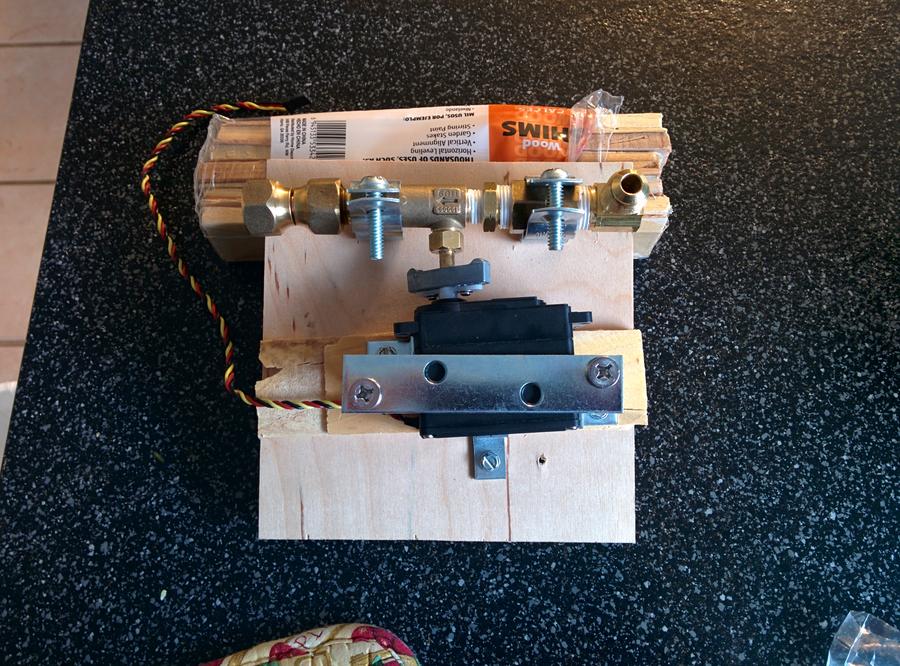

I've also attached a multi-turn servo to a needle valve, so that I can get better control over the temperature setpoint.

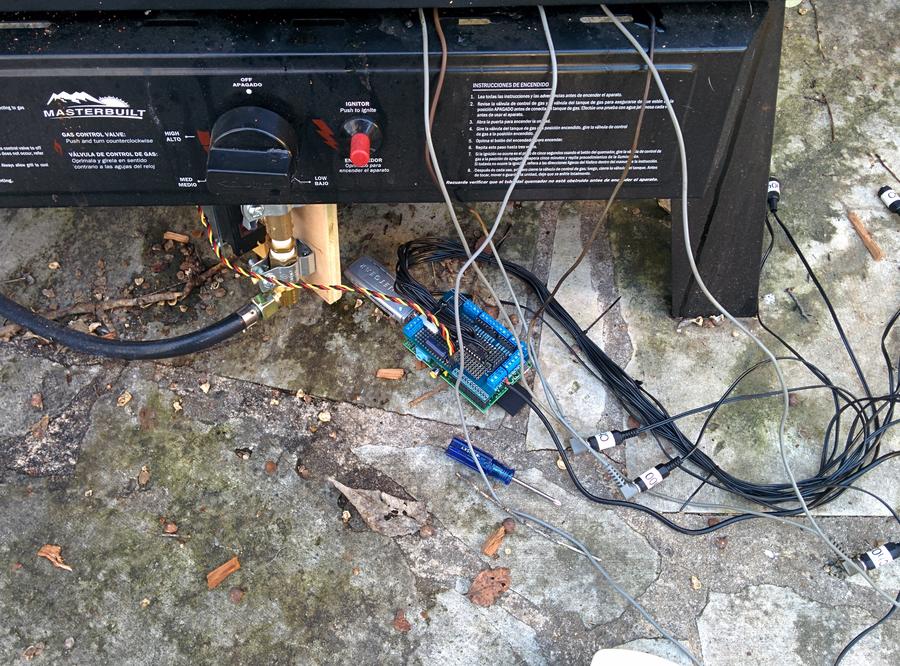

Here it is connected to the smoker. I almost dribbled grease and water on it a few times. I need to extend the servo wiring so I can get it away from the door.

I smoked 3 turkey legs, a whole turkey breast, a chicken, a pork butt, and a brisket. This is only my third smoke, and I had NO trouble with the food. The Smokin'Pi, on the other hand, did give me a bit of frustration. At one point, it crashed and wouldn't reboot for about an hour. You can a big temperature jump in the graph. This is because the Pi wasn't able to log for roughly an hour while I worked on getting it back up and running.

SEVERAL times through the smoke, you can see that I opened the door WIDE open. I knew this caused the temperature to drop drastically, but what I didn't know is that it caused the poultry's temperature to drop significantly as well. The pork and beef handled it much better, most likely because they have a much larger thermal mass. I opened the door many times, mostly to double check the Smokin'Pi's temperature readings. I didn't want to discover that I was cooking the meat to charred embers while I'm inside grinning ear to ear with my perceived cleverness.

I didn't have enough probes to keep one in each piece of meat. I used 5 probes for the smoke. One for cabinet temperature, one for the turkey (started in a turkey leg, moved to breast when legs were done), one for the brisket and one for the pork butt. Throughout the smoke I'd stop the program, change up the firmware, then start the program again. You can kind of see that in the cabinet temperature line as the smoothness changes. Pretty early on in the smoke, there was a large temperature swing where it just kept oscillating. After I quit opening the damned door, and after multiple changes to the code, it became quite stable when I lowered the setpoint to 225°C. I was worried that the butt wouldn't be done until midnight so I bumped the setpoint back up to to 250°C and it started oscillating again. I'm fine with the temperature oscillation itself, but oscillation = servo wear and I don't want to replace the servo every smoke.

Turkey Legs! I smoked 3 of them, but one didn't make it to the aluminum foil. He will be remembered fondly.

Turkey breast. Came out pretty good, but not as juicy as I'd like though it was far from dry. I brined it overnight (1 gallon water, 1 cup sugar, 3/4 cup salt) and smoked it breast side up directly on the rack. Is there a better position for turkey? Or is turkey just not going to be very juicy compared to chicken?

Smoked a chicken for my neighbor. Came out pretty darn good, though it took a little longer to smoke than I expected it to take. Doesn't matter, the Smokin'Pi let me know when it was done!

My first brisket! Came out pretty damned good. Nice temperature, nice flavor, good bark! I smoked it fat-cap-up and in an aluminum tray.

Almost lost a finger as I was slicing the brisket. It was difficult to keep my left hand out of the meat while the right hand was slicing

Would have liked a bit thicker smoke ring, but I was damn happy with the results as they were!

Smoked a small pork butt for my neighbor, same one that got the chicken. This was smoked in a tray as well, but very little juices were available to pour back over the meat. The last pulled pork I did, I added some apple juice to the tray. I forgot to do it for this one, and that is likely why I didn't have much juice at the end. I couldn't even separate any from the fat.

Future plans for the Smokin'Pi include:

I did all of this in one week, and I'm quite happy with the results.

What you see below is the add-on board with the analog to digital converter. The cables coming off of it allow for connecting to temperature probes.

I've also attached a multi-turn servo to a needle valve, so that I can get better control over the temperature setpoint.

Here it is connected to the smoker. I almost dribbled grease and water on it a few times. I need to extend the servo wiring so I can get it away from the door.

I smoked 3 turkey legs, a whole turkey breast, a chicken, a pork butt, and a brisket. This is only my third smoke, and I had NO trouble with the food. The Smokin'Pi, on the other hand, did give me a bit of frustration. At one point, it crashed and wouldn't reboot for about an hour. You can a big temperature jump in the graph. This is because the Pi wasn't able to log for roughly an hour while I worked on getting it back up and running.

SEVERAL times through the smoke, you can see that I opened the door WIDE open. I knew this caused the temperature to drop drastically, but what I didn't know is that it caused the poultry's temperature to drop significantly as well. The pork and beef handled it much better, most likely because they have a much larger thermal mass. I opened the door many times, mostly to double check the Smokin'Pi's temperature readings. I didn't want to discover that I was cooking the meat to charred embers while I'm inside grinning ear to ear with my perceived cleverness.

I didn't have enough probes to keep one in each piece of meat. I used 5 probes for the smoke. One for cabinet temperature, one for the turkey (started in a turkey leg, moved to breast when legs were done), one for the brisket and one for the pork butt. Throughout the smoke I'd stop the program, change up the firmware, then start the program again. You can kind of see that in the cabinet temperature line as the smoothness changes. Pretty early on in the smoke, there was a large temperature swing where it just kept oscillating. After I quit opening the damned door, and after multiple changes to the code, it became quite stable when I lowered the setpoint to 225°C. I was worried that the butt wouldn't be done until midnight so I bumped the setpoint back up to to 250°C and it started oscillating again. I'm fine with the temperature oscillation itself, but oscillation = servo wear and I don't want to replace the servo every smoke.

Turkey Legs! I smoked 3 of them, but one didn't make it to the aluminum foil. He will be remembered fondly.

Turkey breast. Came out pretty good, but not as juicy as I'd like though it was far from dry. I brined it overnight (1 gallon water, 1 cup sugar, 3/4 cup salt) and smoked it breast side up directly on the rack. Is there a better position for turkey? Or is turkey just not going to be very juicy compared to chicken?

Smoked a chicken for my neighbor. Came out pretty darn good, though it took a little longer to smoke than I expected it to take. Doesn't matter, the Smokin'Pi let me know when it was done!

My first brisket! Came out pretty damned good. Nice temperature, nice flavor, good bark! I smoked it fat-cap-up and in an aluminum tray.

Almost lost a finger as I was slicing the brisket. It was difficult to keep my left hand out of the meat while the right hand was slicing

Would have liked a bit thicker smoke ring, but I was damn happy with the results as they were!

Smoked a small pork butt for my neighbor, same one that got the chicken. This was smoked in a tray as well, but very little juices were available to pour back over the meat. The last pulled pork I did, I added some apple juice to the tray. I forgot to do it for this one, and that is likely why I didn't have much juice at the end. I couldn't even separate any from the fat.

Future plans for the Smokin'Pi include:

- replacing my current servo control routines with a PID control loop. This should aid in getting the needle valve set where it needs to be rather than spinning back and forth constantly.

- Smartening up the main control loop so I can use a higher smoking temperature (like 270°F or so) until all meats are out of the danger zone, then drop back down to the appropriate temperature for the meat in the smoker

- Implementing a web interface so not everything has to be done at the command line. Right now, all you see is a screen full of somewhat intimidating information that continually scrolls by. The web interface will allow for a much simpler control and monitoring capabilities

- Implement flame detection (have the hardware, just not the software) so in case the flame blows out the needle valve can be closed

- MAYBE add auto-ignition so it can attempt to light the flame when it goes out

- Text or Email notification when milestones are reached (e.g. text message when the meat is within 5°F of final temperature

I did all of this in one week, and I'm quite happy with the results.

Last edited: