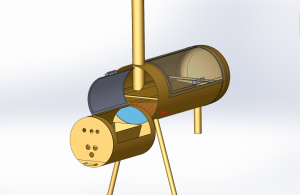

Designing a reverse flow smoke from two gas canisters all going to plan based around the guide provided by dave on this forum. I have been trawling through threads but can't find an answer to what must be a common occurance.

Given I have two round cylinders for the FB and CC I'm wondering how the area under the RF plate is kept the same as the area between the FB and CC.

Does the area under the RF plate need to be the same as the CC/FB area? If so how is this normally accomplished since with a flat RF plate the area will be larger?

Thanks in advance.

Numbers below as starting point.

Cooking chamber volume 5661 cubic inches.

minmum Firebox volume (can be larger)

0.33 1868.13

Firebox to cooking chamber opening

0.004 22.644

Cross section of chamber under reverse flow plate

0.004 22.644

Area required at the end of the reverse flow plate

0.004 22.644

Exhaust stack volume above cooking chamber

0.022 124.542

Firebox inlet above and gelow grate total

0.001 5.661

Given I have two round cylinders for the FB and CC I'm wondering how the area under the RF plate is kept the same as the area between the FB and CC.

Does the area under the RF plate need to be the same as the CC/FB area? If so how is this normally accomplished since with a flat RF plate the area will be larger?

Thanks in advance.

Numbers below as starting point.

Cooking chamber volume 5661 cubic inches.

minmum Firebox volume (can be larger)

0.33 1868.13

Firebox to cooking chamber opening

0.004 22.644

Cross section of chamber under reverse flow plate

0.004 22.644

Area required at the end of the reverse flow plate

0.004 22.644

Exhaust stack volume above cooking chamber

0.022 124.542

Firebox inlet above and gelow grate total

0.001 5.661