Hey guys. So I've just recently started a backyard reverse flow smoker build. I'll just say that I've outgrown many aspects of my store-bought cooker, and... well, I just always have to be building/working on something, so why not a grill as my next project ;) Only recently have I started visiting this section of the forum too, and it seems like a cool spot to hang out for a bit, and share my build, so here it goes.

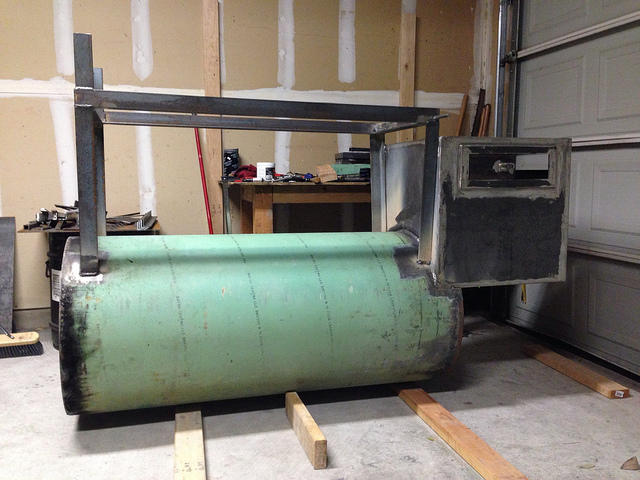

This is my first grill build (of what I'm sure will be at least a few more to come) and I wont even claim to be an expert or experienced metal worker, but its been fun so far. The plan is a 24" diameter cooking chamber with a planned length of 48". Not 100% set in stone as I've yet to be able to get ahold of any pipe. The past few days I've been toying around with the idea of trying to find a tank, probably 120 gallon if possible. 150 might be pushing what I'm looking for size wise but will roll with it for the right price. We will see where that goes here in the next few weeks.

As of right now, I am just about done with my firebox. The box is a 22" square box with 4" x 7" air inlets on each side. I've run my numbers through the calculator and my air inlets are almost twice what I need, but I wanted the ability to close one side off if necessary (due to weather/wind) My fire grate is about 4.5 inches off of the bottom. I believe I will still have plenty of room for a fire and flame, but will have plenty of room for ash and air under the fire as well. I will put some expanded metal over the air intakes and I still need one more piece of strapping on the top edge of the door opening. Still need to work on the fire grate as well.

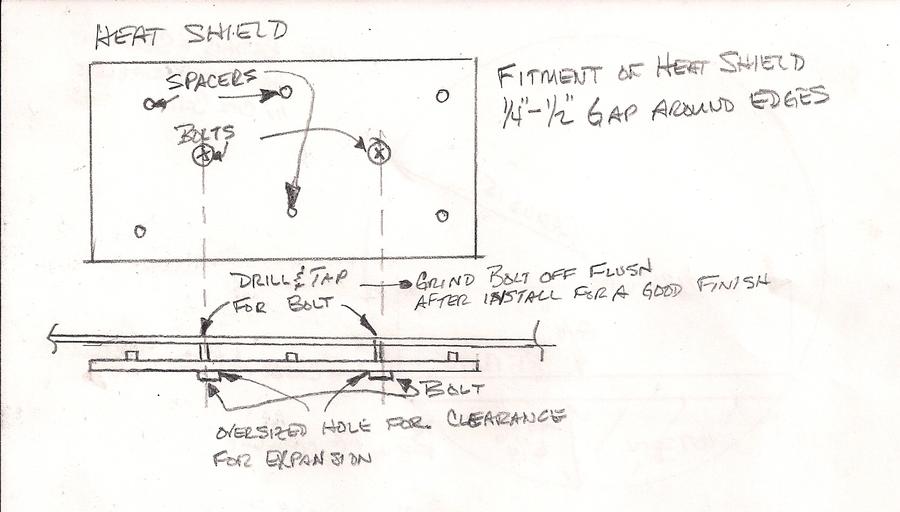

I had not originally planned any type of deflector plate or anything on the top of the firebox, but now I am starting wonder if I should while its going together. I've seen different designs, and I'm not sure if I want to suspend a plate from the top, or maybe add a layer of 1" insulation to the top. I know insulation isn't really needed here in Texas and I do not want to do the whole box, this would just be to help preserve the top of the box, and possibly help with heat and fuel efficiency... in theory anyway. Maybe I've mis-understood and this isn't even necessary in my case. So, thoughts on that would be appreciated. If I were to do so however, the original plan was to mate the reverse flow plate up flush with the top of the firebox. If I suspend a plate, that I would have to adjust for that and possibly mount my firebox a little higher than planned. Or the other thought I had was to just add 1" insulation to the top and weld in another plate... ??

Anyway, those are some random thoughts. All build threads are worthless with out pics, so heres the fun part :p Thanks for looking!

This is my first grill build (of what I'm sure will be at least a few more to come) and I wont even claim to be an expert or experienced metal worker, but its been fun so far. The plan is a 24" diameter cooking chamber with a planned length of 48". Not 100% set in stone as I've yet to be able to get ahold of any pipe. The past few days I've been toying around with the idea of trying to find a tank, probably 120 gallon if possible. 150 might be pushing what I'm looking for size wise but will roll with it for the right price. We will see where that goes here in the next few weeks.

As of right now, I am just about done with my firebox. The box is a 22" square box with 4" x 7" air inlets on each side. I've run my numbers through the calculator and my air inlets are almost twice what I need, but I wanted the ability to close one side off if necessary (due to weather/wind) My fire grate is about 4.5 inches off of the bottom. I believe I will still have plenty of room for a fire and flame, but will have plenty of room for ash and air under the fire as well. I will put some expanded metal over the air intakes and I still need one more piece of strapping on the top edge of the door opening. Still need to work on the fire grate as well.

I had not originally planned any type of deflector plate or anything on the top of the firebox, but now I am starting wonder if I should while its going together. I've seen different designs, and I'm not sure if I want to suspend a plate from the top, or maybe add a layer of 1" insulation to the top. I know insulation isn't really needed here in Texas and I do not want to do the whole box, this would just be to help preserve the top of the box, and possibly help with heat and fuel efficiency... in theory anyway. Maybe I've mis-understood and this isn't even necessary in my case. So, thoughts on that would be appreciated. If I were to do so however, the original plan was to mate the reverse flow plate up flush with the top of the firebox. If I suspend a plate, that I would have to adjust for that and possibly mount my firebox a little higher than planned. Or the other thought I had was to just add 1" insulation to the top and weld in another plate... ??

Anyway, those are some random thoughts. All build threads are worthless with out pics, so heres the fun part :p Thanks for looking!