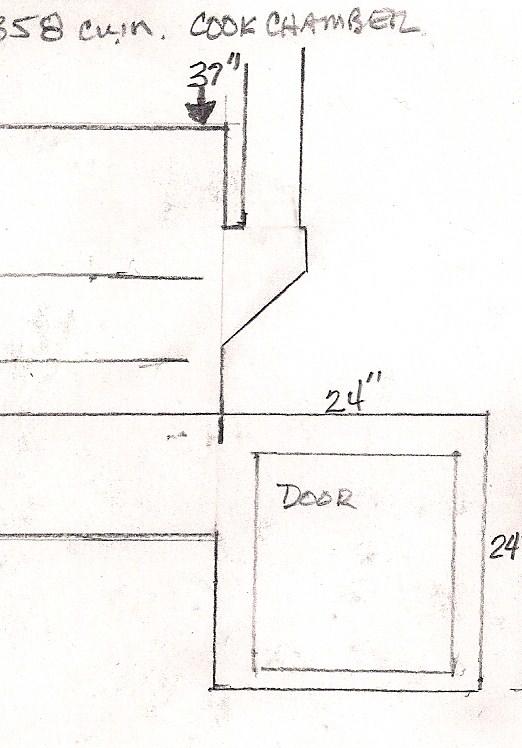

I just recently turned my grill into a reverse flow and am having problems with it. First off the CC is a 16" diameter and 34" long. That gives 6832.64" cube of air space. Feldon's recommends 2277.55" cube for the fire box. Mine is 18"x15.5"x9" giving a total of 2511.00" cube. That is 233.45" cube oversize. The exhaust is 3" ID and is 16" above CC. Recommended was 17.77". It was over 20" and I cut it with a reciprocating saw and got it just a little short. The FB to CC opening follows the contour of the CC so it is a 8" radius at 2.5" tall, giving 20.064" square of area. Recommended was 20.09" square. The RF plate is 13.5" wide and sits 3.75 inches from the bottom giving an area of 35.287" square. The only thing I am not sure of is the opening around the end of the RF plate, however after not being able to gain temps I did take it back to work and shortened it by 1.5" to make the opening bigger.As you can see the end of the tank is rounded and after shortening the plate it comes back into the straight sides, so I am not sure how to calculate that. Air intake is 3.25" diameter only one needed. I did go back and add another intake higher up to see if that would help it to draw the heat better. Even with RF plate installed the smoke poured out like crazy, however I was lucky to get 190* inside. I can take the RF plate out and open the old exhaust like a straight flow and get over 400*. Install RF plate, temp drops. With RF plate in place I can even lay my hand on the underside of the CC and leave it without burning myself. This is my first attempt at a reverse flow so I would appreciate any input you guys have. If I had access to what I needed here at home I would try to raise the area under the RF plate just to see what would happen. if I cannot get this right I will just move my better exhaust and use it as a straight flow. Here are a couple of pics.

.

.

Last edited: