Hey all,

I've been smoking on an electric, and pellet grill for a few months and decided to jump into the stickburner world. I picked up a used custom build trailer unit from a friend. 120 gal CC, 24" cube firebox. Seems to be a nice unit.

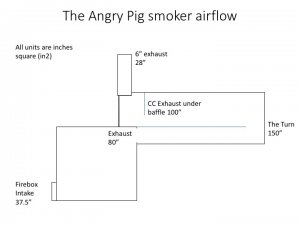

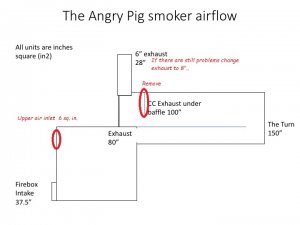

While firing it up for the first time, it seemed difficult to reach temp's. I also noticed that the CC was always jam-packed with smoke when I opened it up to inspect. I'm wondering if the exhaust baffle plate is too low under the exhaust stack. I've looked around the site and seen some with plates, and some without. Take a look at the pics. Is there a spec for the drop on an exhaust baffle?

Thanks in advance!

I've been smoking on an electric, and pellet grill for a few months and decided to jump into the stickburner world. I picked up a used custom build trailer unit from a friend. 120 gal CC, 24" cube firebox. Seems to be a nice unit.

While firing it up for the first time, it seemed difficult to reach temp's. I also noticed that the CC was always jam-packed with smoke when I opened it up to inspect. I'm wondering if the exhaust baffle plate is too low under the exhaust stack. I've looked around the site and seen some with plates, and some without. Take a look at the pics. Is there a spec for the drop on an exhaust baffle?

Thanks in advance!