I have a medium Egg that has suddenly stopped heating up. Pretty much nothing gets it past 300 degrees. Vents top and bottom are wide open. Different charcoal, different lighters, new thermometer, same result. I’ve even tried blowing a fan through the bottom vent. I’ve put the cap on and taken it off. Nothing. Charcoal simply won’t heat up. No visible indication of any crack. Frustrating.

Question

- Thread starter timbonole

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Agree broth Brian. Also have you checked the gasket? My buddies was doing that and he replaced his

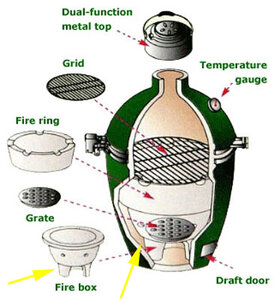

Check and see if you have ash built up between the firebox and the sides of the base. This can interrupt airflow. You might even have to remove the firebox to get it all if it's really fine ash.

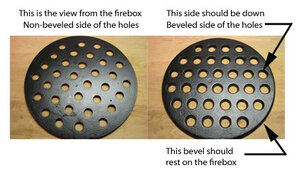

Also make sure your charcoal grate is in correctly. The holes have a bevel, and the bevel should be on the clean-out side, not the firebox side. I'll look for a photo, I've even seen dealers make this mistake.

Also make sure your charcoal grate is in correctly. The holes have a bevel, and the bevel should be on the clean-out side, not the firebox side. I'll look for a photo, I've even seen dealers make this mistake.

As I say, I changed the thermometer. However I think that might still be an issue. I kept the old one and held it inside the Egg just now and it read much closer to what it should be. As soon as the thing cools down, I’ll check to see if the new one is installed properly. There seems to be more play in it than there should be.Have tried another thermometer?

I know the air flow is fine. I literally scooped out ashes and burnt charcoal by hand. I will check the bevel. That sounds like a possibility

I don't trust ones mounted in the tops. I would use a digital mounted at grate level one if you have it.

Okay Tim, oh and welcome aboard.... this might help out. Click the photo's to supersize. Most people think the beveled edge will help ash fall into the bottom the egg, and put them facing up. But... if the bevels are up the ash fills the holes and restricts airflow. When the non-beveled side is up, the ash falls through with less restriction.

The tool you can make at home is a 'wiggle rod', actually a Woody Wiggle Rod, named after Char-Woody one of the early ceramic cooks and the guy that got me into ceramic cookers over 20 years ago. My instructions pretty much size up the wiggle technique. I wiggle my coals after a few hours, or anytime I have a stubborn fire. I also wiggle them during an overnight cook, about 30 minutes before I catch a few winks. Wiggling is insurance that you have good airflow. The motion is GENTLE, sort of poking up and wiggling side-to-side. You can actually notice a change in exhaust smoke while wiggling.

The tool you can make at home is a 'wiggle rod', actually a Woody Wiggle Rod, named after Char-Woody one of the early ceramic cooks and the guy that got me into ceramic cookers over 20 years ago. My instructions pretty much size up the wiggle technique. I wiggle my coals after a few hours, or anytime I have a stubborn fire. I also wiggle them during an overnight cook, about 30 minutes before I catch a few winks. Wiggling is insurance that you have good airflow. The motion is GENTLE, sort of poking up and wiggling side-to-side. You can actually notice a change in exhaust smoke while wiggling.

I'm not talking about ash in the bottom clean-out area. I'm talking ash between the outside of the firebox and the inside of the base. There is about a 1" gap from the base.... all the way around the firebox. I have a mini ash tool to clear that ash out.

Last edited:

I had no ideaThe yellow arrows show the space between the firebox foot and the inside wall of the base where ash will build up. It will be somewhat fine like flour.

View attachment 486663

The easiest way is to remove the fire ring, then lift the fire basket out. I cook a lot on my Eggs, and only do this twice a year. But if you have never done it, this might be the ticket. Just be super careful with the components. Sometimes they are cracked and you never notice it because ash is hiding the crack.

For cleaning I found some scrap stainless steel banding on a jobsite, it's 3/4" wide and very flexible, and I bent a short 'L' at the end to make a mini ash tool. So instead of going straight in to the ash compartment I angle it 45° and get my tool in that small compartment and drag ash out.

For cleaning I found some scrap stainless steel banding on a jobsite, it's 3/4" wide and very flexible, and I bent a short 'L' at the end to make a mini ash tool. So instead of going straight in to the ash compartment I angle it 45° and get my tool in that small compartment and drag ash out.

The easiest way is to remove the fire ring, then lift the fire basket out. I cook a lot on my Eggs, and only do this twice a year. But if you have never done it, this might be the ticket. Just be super careful with the components. Sometimes they are cracked and you never notice it because ash is hiding the crack.

For cleaning I found some scrap stainless steel banding on a jobsite, it's 3/4" wide and very flexible, and I bent a short 'L' at the end to make a mini ash tool. So instead of going straight in to the ash compartment I angle it 45° and get my tool in that small compartment and drag ash out.

View attachment 486677

OK. Done. There was a ton of ash in there, and like you said, flour-like.

I’m also pretty sure I had bottom grate upside down. We will see what kind of results I get, later today or tomorrow. Thanks

The easiest way is to remove the fire ring, then lift the fire basket out. I cook a lot on my Eggs, and only do this twice a year. But if you have never done it, this might be the ticket. Just be super careful with the components. Sometimes they are cracked and you never notice it because ash is hiding the crack.

For cleaning I found some scrap stainless steel banding on a jobsite, it's 3/4" wide and very flexible, and I bent a short 'L' at the end to make a mini ash tool. So instead of going straight in to the ash compartment I angle it 45° and get my tool in that small compartment and drag ash out.

View attachment 486677

An Egg's design is so simple, I was hoping that's all you needed to get it back to acting like new again. Just make sure it doesn't take off like a rocket to 700°.OK. Done. There was a ton of ash in there, and like you said, flour-like.

I’m also pretty sure I had bottom grate upside down. We will see what kind of results I get, later today or tomorrow. Thanks

It’s at 600 now; should begin settling down in a moment. Got some wings to throw on.An Egg's design is so simple, I was hoping that's all you needed to get it back to acting like new again. Just make sure it doesn't take off like a rocket to 700°.

all seems to be well. Settling in at 300 with plate on (yes, I do wings indirect)It’s at 600 now; should begin settling down in a moment. Got some wings to throw on.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 31

- Views

- 8K

- Replies

- 33

- Views

- 45K

- Replies

- 29

- Views

- 22K

- Replies

- 4

- Views

- 4K

Hot Threads

-

Well. Look what Santa dropped off early!

- Started by Steve H

- Replies: 28

- Blowing Smoke Around the Smoker.

-

The Best Egg Salad - Enabler Version

- Started by Chris_in_SoCal

- Replies: 26

- ABT's and all things Appetizers

-

Chicago Cracker-Thin 'Za

- Started by Quiganomics

- Replies: 16

- Pizza

-

Featured Sous Vide Chuck Tender

- Started by BrianGSDTexoma

- Replies: 13

- Sous Vide Cooking