Just kidding ..I cut the half moon tonight and I was pretty nervous ..I wussed out on using a torch ..I filled with soap and water and used a cutt off wheel and a sawzall ..I'm going to use a torch for the doors ...but ehat a relief I was stressing all week about it

Picked up a propane tank

- Thread starter kdfiter

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

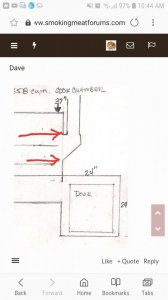

I made my height of my half moon cutout at 12 in ( a little big because I'm going to put 3 in channel for grease trap) if I put the end of my reverse flow plate at 12 in from the end ..my cooking grate will over hang by 2 and not catch the grease..hope that make sense

Attachments

kmmamm

Meat Mopper

- Apr 30, 2016

- 238

- 87

I would be more concerned about potential turbulence associated with locating the drain tube so close to the bell. So long as the total volume of the opening is at least as large as the firebox-cooking chamber opening, it shouldn't pose a restriction problem. (Maybe other builders will weigh in here.) Alternatively instead of stretching the entire rf plate and grease channel, you can keep it at 12 “ and fabricate an end plate that flairs up and out at an angle such that it extends a couple inches beyond the end of the grate. (Similar to how a gravity flow wagon flairs out from the bottom) That will keep the drain tube plumbing out of the bell end which should minimize restrictions and turbulence at the end of the rf plate.

I cut my doors today and I got pretty lucky they didnt spring to much ..so after reading a few threads I've decided I'm going to make a plenum for the stack.ive been searching threw the forums seeing if theres any kind of exact measurements to make it and I couldnt find anything .my question is ..do you make the opening of the plenum the same size as the stack (I'm going with 6 in) or do I make it bigger also the and of the bottom of the plenum is that just at 45 degrees

Attachments

Last edited:

Johndeere1

Fire Starter

Your build looks great. Why did you decide to go with a plenum on your stack? Just curious. I looked at doing that also but just ended up putting the stack straight into the top of CC.

Everthing I've been reading says you get better air flow ..I've done smaller reverse flows and had my stack just go straight down and they seem to work fine ..I figure maybe I'll build a plenum and give it a try and see if theres much of a difference

Johndeere1

Fire Starter

Well made a little progress this weekend and after debating whether or not to build a plenum.. I decided to just build it ..it was a little time consuming but I got some good advice from kmammam and got er done ..I also sealed the inside doors with flat stock .I'm building this solo so everything seems to take forever

Well made a little progress this weekend and after debating whether or not to build a plenum.. I decided to just build it ..it was a little time consuming but I got some good advice from kmammam and got er done ..I also sealed the inside doors with flat stock .I'm building this solo so everything seems to take forever

Attachments

Johndeere1

Fire Starter

It's going ok ..I've been battling a bad cold and now where getting hammered with snow up here in wi ..I'm kind of as far as I can go with the tank until I get my fire box going..so I started on the trailer last weekend ..I have a scrapper that I get some of my steel from and he hooked me up with 3 in channel iron but the only problem was that it was painted with orange powder coat so I spent the whole weekend sanding and painting ..when I get this steel from my scrap guy its cheaper but sometimes it's just more work ..

So I got done with some progress this weekend ..after battling -55 degree temps ,2 feet of snow and a bad cold and a bum ankle I was able to get most of my trailer done (still have to wire it) this weekend ..I made a removable tongue (we have a lot of thief's in this town) that I thought turned out pretty good.. the trailers upside down in this pict..as you probaly can tell I have limited work space ..now I'm going to make a Aframe to hoist this tank

Attachments

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 6

- Views

- 3K

- Replies

- 2

- Views

- 9K

- Replies

- 0

- Views

- 1K

- Replies

- 12

- Views

- 2K

- Replies

- 10

- Views

- 733

Hot Threads

-

Crazy Wind - 65-80 Mph tossing semi’s today….

- Started by civilsmoker

- Replies: 40

- Blowing Smoke Around the Smoker.

-

Moving to St. Louis area. Info needed.

- Started by SmokingUPnorth

- Replies: 23

- Blowing Smoke Around the Smoker.

-

Oak leaf #7 cleaver

- Started by Timber II

- Replies: 18

- Blowing Smoke Around the Smoker.

-

suggest me best thermometer

- Started by olivia11

- Replies: 18

- General Discussion