Hello and Merry Christmas,

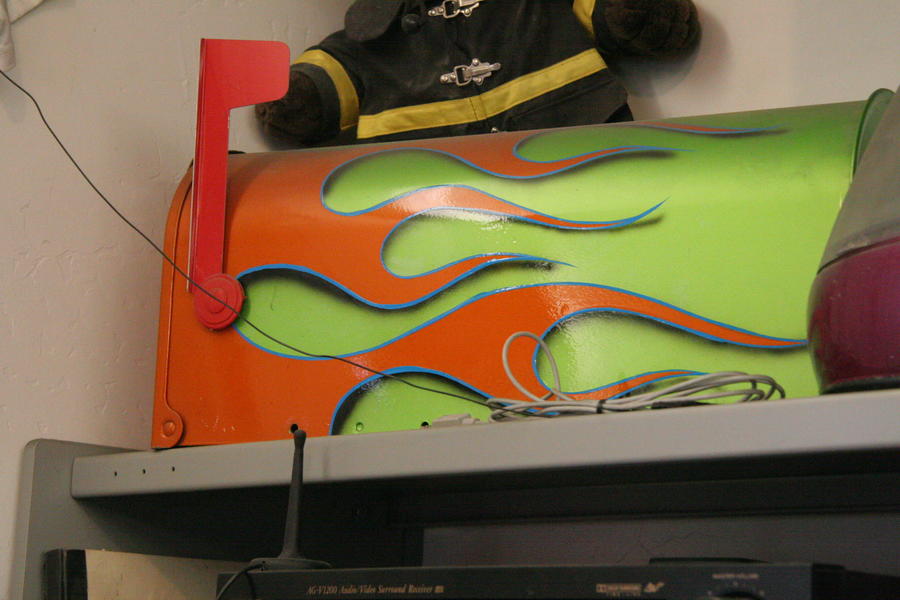

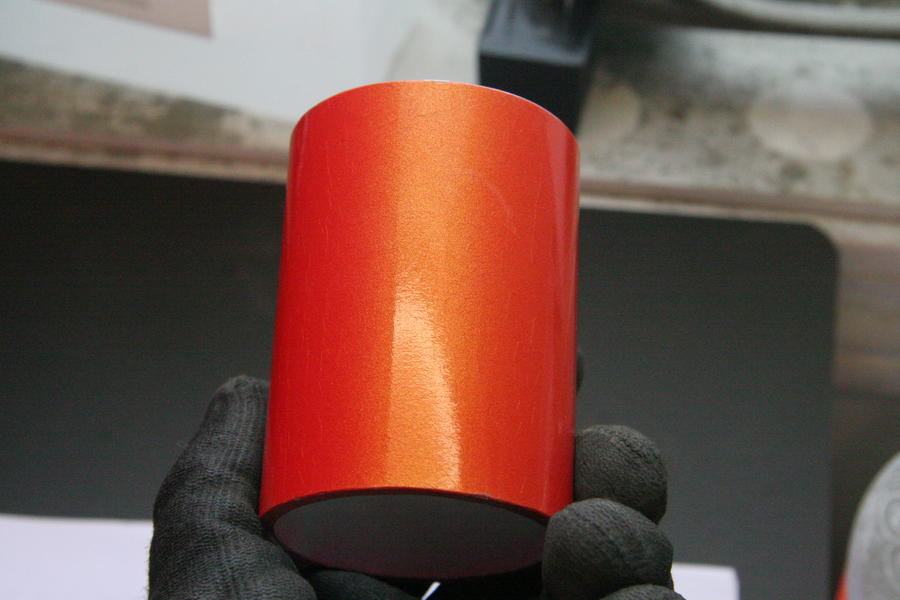

I figured I'd start a thread on this fridge conversion since it seems nobody else has tried it. Pictures included. I will post as it progresses. I have a 40s or 50s era Admiral fridge. Everything is steel, the inter tub is enameled steel. I have gutted it already and have started the conversion. Purchased the Smoke Daddy pellet burner unit a week or so ago. Fridge is prepped for mounting of the pellet unit. I need to make flashings, a heat deflector and a drip deflector. I know a guy in the metal fab business, so i am going to try to get stainless flashings made and a stainless inner door skin, the original inner door skin is steel but contoured in a way that will prevent me from making my own door seal. I will need to re-insulate, I will use rock wool. The lower part of the interior tub has a nice depression in the bottom of it to collect fat. I have a drain installed in it and it is plumbed to the outside to a 3/4" ball valve. I plan on giving it a kick ass flame paint job, like the mailbox. Only the body will be the orange shown with green and purple flames. I will keep everybody posted on the progress.

Thanks

I figured I'd start a thread on this fridge conversion since it seems nobody else has tried it. Pictures included. I will post as it progresses. I have a 40s or 50s era Admiral fridge. Everything is steel, the inter tub is enameled steel. I have gutted it already and have started the conversion. Purchased the Smoke Daddy pellet burner unit a week or so ago. Fridge is prepped for mounting of the pellet unit. I need to make flashings, a heat deflector and a drip deflector. I know a guy in the metal fab business, so i am going to try to get stainless flashings made and a stainless inner door skin, the original inner door skin is steel but contoured in a way that will prevent me from making my own door seal. I will need to re-insulate, I will use rock wool. The lower part of the interior tub has a nice depression in the bottom of it to collect fat. I have a drain installed in it and it is plumbed to the outside to a 3/4" ball valve. I plan on giving it a kick ass flame paint job, like the mailbox. Only the body will be the orange shown with green and purple flames. I will keep everybody posted on the progress.

Thanks