- Nov 11, 2020

- 4

- 3

I have an Oklahoma Joe Highland Offset Smoker.

If I use the fire box as normal it seems very inefficient.

I use 4 temperature probes.

Two of the probes are placed on the grill rack either side of the meat.

Any time I open the top stack damper the heat just goes across the top of the cooking chamber and out the chimney.

The top built in temperature gauge says 350 to 400°F while the long range four probe Wi-Fi temp gauge shows the meat cooking level is 175-225°F

The meat is sitting where humans are told to go in a fire...stay low down out of the heat and smoke.

It takes a large amount of natural charcoal and cherry wood or mesquite to cook. I normally use charcoal with wood chunks to flavor the smoke, not wood.

If I completely close the chimney damper it allows the heat to build up and work its way down to where the meat is but risks having too much smoke linger around instead of moving through the meat.

It takes a large amount of fuel. It’s also hard to keep the temperature up.

When I build my fire with just natural charcoal in the cooking chamber instead of the fire box and completely shut the top damper then regulate the temperature using the firebox damper I use about one third less fuel, the meat cooks faster, in eight instead of ten hours to get to 205°F internal temp.

On windy days I close both dampers and cover the grill with a clean welding blanket.

I can maintain the temperature for the whole 8 hour cook time with one load of 10 pounds natural charcoal.

The smoke flavor is better because I’m not adding new wood or charcoal every hour. Less acrid smoke.

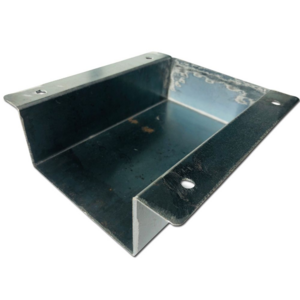

The only problem I have had with this approach is the lip between the firebox and the cooking area makes ash clean out harder.

I also loose half of my cooking area to the fire when offset smoking but I can smoke then sear steaks with the same setup.

Yes after reading some research on steaks I cook them first then sear them but that’s a whole other topic.

The results seem better, better smoke flavor due to burning less acrid new fuel.

It takes less stoking, is more setup and forget and is more efficient on the fuel.

What would be the best upgrade and fuel efficiency improvement?

~Kevin

If I use the fire box as normal it seems very inefficient.

I use 4 temperature probes.

Two of the probes are placed on the grill rack either side of the meat.

Any time I open the top stack damper the heat just goes across the top of the cooking chamber and out the chimney.

The top built in temperature gauge says 350 to 400°F while the long range four probe Wi-Fi temp gauge shows the meat cooking level is 175-225°F

The meat is sitting where humans are told to go in a fire...stay low down out of the heat and smoke.

It takes a large amount of natural charcoal and cherry wood or mesquite to cook. I normally use charcoal with wood chunks to flavor the smoke, not wood.

If I completely close the chimney damper it allows the heat to build up and work its way down to where the meat is but risks having too much smoke linger around instead of moving through the meat.

It takes a large amount of fuel. It’s also hard to keep the temperature up.

When I build my fire with just natural charcoal in the cooking chamber instead of the fire box and completely shut the top damper then regulate the temperature using the firebox damper I use about one third less fuel, the meat cooks faster, in eight instead of ten hours to get to 205°F internal temp.

On windy days I close both dampers and cover the grill with a clean welding blanket.

I can maintain the temperature for the whole 8 hour cook time with one load of 10 pounds natural charcoal.

The smoke flavor is better because I’m not adding new wood or charcoal every hour. Less acrid smoke.

The only problem I have had with this approach is the lip between the firebox and the cooking area makes ash clean out harder.

I also loose half of my cooking area to the fire when offset smoking but I can smoke then sear steaks with the same setup.

Yes after reading some research on steaks I cook them first then sear them but that’s a whole other topic.

The results seem better, better smoke flavor due to burning less acrid new fuel.

It takes less stoking, is more setup and forget and is more efficient on the fuel.

What would be the best upgrade and fuel efficiency improvement?

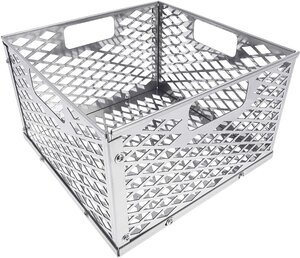

- Install a plate across half the cooking chamber from the firebox forcing heat under and up through the meat? I would leave the chimney in place. It seems moving the chimney would just allow the heat to escape closer to the source and not move through the meat. True reverse flow would require a good seal between the plate and smoker walls to keep heat from escaping and going out the chimney.

- Set up a temperature controlled fan on the firebox and switch from charcoal to pre-warmed dry oak with charcoal starter for fuel?

- Cut down the lip between the firebox and cooking chamber to make ash clean-out easier and continue building the fire in the cooking chamber to both offset smoke and direct sear?

- Maybe a combination of firebox fan, lip cut down, removable plate and switching to charcoal starter and wood for smoking?

~Kevin