Well between me and Jay, we decided it was time to build a new sausage smoker at his house that would hold more than my build. http://www.smokingmeatforums.com/t/149279/sausage-maker-electric-build

Took the basic idea from Jerry's smoke house at the North Florida gathering. Going to try and run it off the electric PID I built for mine. It was only 1800 watts single phase. We are going to insulate the hell out of it so hope it will get to 180 degrees with the current set up. Will be 4 X 4 X 8. The inside will be cement board.. For the roof vent was thinking of using a ridge vent and cut only a small section out to start to see how the amazing tube smoker burn. If we don't get enough draw keep opening the ridge opening until we do. Thoughts? Was just an idea instead of a traditional vent with damper. We have a hard time finding vent parts here in Northwest Florida.

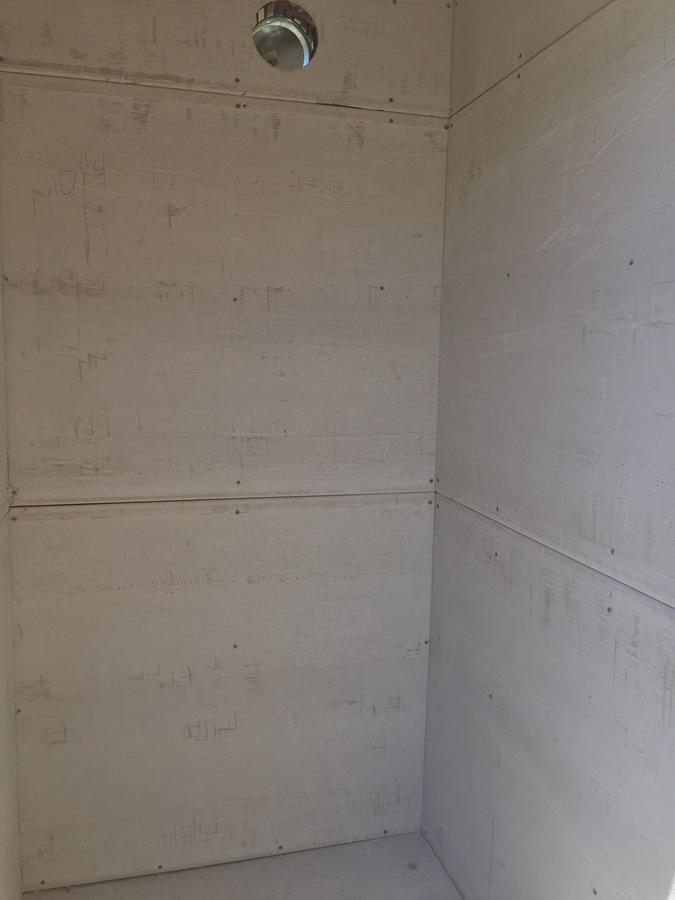

Hopefully have walls next weekend.

80 pound bags of sac-crete weigh more than they used to!!!

Took the basic idea from Jerry's smoke house at the North Florida gathering. Going to try and run it off the electric PID I built for mine. It was only 1800 watts single phase. We are going to insulate the hell out of it so hope it will get to 180 degrees with the current set up. Will be 4 X 4 X 8. The inside will be cement board.. For the roof vent was thinking of using a ridge vent and cut only a small section out to start to see how the amazing tube smoker burn. If we don't get enough draw keep opening the ridge opening until we do. Thoughts? Was just an idea instead of a traditional vent with damper. We have a hard time finding vent parts here in Northwest Florida.

Hopefully have walls next weekend.

80 pound bags of sac-crete weigh more than they used to!!!

Last edited: