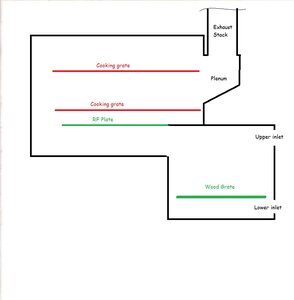

So I have been using a vertical propane smoker for convenience but dearly miss the flavor that my old offset produced. Having recently purchased a new welding machine, the only logical option is to build a 250gal reverse flow and a trailer for it to be mounted on.

I knew my FIL had an extra 250 gal tank that I could get for cheap. He also had several different lengths of 5" square tubing, some angle iron and other pieces of random steel that he offered to go towards my project. All I needed to find was a reverse flow plate and some plate for my firebox. I called a local scrap yard and they said we have a big stack of thick plate you can come look at.

The plate they had was plasma cut 5/8" and were all exactly the same size 2' 10.75" x 2' 6.75". Nice perfectly square edges!!! Jackpot!!! I went home beveled the edges, welded them up into a monster of a firebox, made a door, door handles, latches.

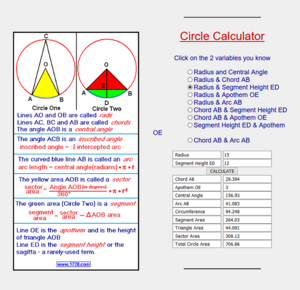

Then I found feldons calculator.

My cooking chamber is 250gal or somewhere around 58,000 cubic inches which means my firebox should be around 19,200 cubic inches. My firebox as built is closer to 28,000 cubic inches.

I can see only 2 good options here.

1. I haven't welded the back plate on yet and could cut the length of the firebox from 34" long to whatever number you more experienced folks would reccomend

2. Look for a 325gal tank and have a bigger smoker than I will ever need.

What should I do here?

Thanks, John

I knew my FIL had an extra 250 gal tank that I could get for cheap. He also had several different lengths of 5" square tubing, some angle iron and other pieces of random steel that he offered to go towards my project. All I needed to find was a reverse flow plate and some plate for my firebox. I called a local scrap yard and they said we have a big stack of thick plate you can come look at.

The plate they had was plasma cut 5/8" and were all exactly the same size 2' 10.75" x 2' 6.75". Nice perfectly square edges!!! Jackpot!!! I went home beveled the edges, welded them up into a monster of a firebox, made a door, door handles, latches.

Then I found feldons calculator.

My cooking chamber is 250gal or somewhere around 58,000 cubic inches which means my firebox should be around 19,200 cubic inches. My firebox as built is closer to 28,000 cubic inches.

I can see only 2 good options here.

1. I haven't welded the back plate on yet and could cut the length of the firebox from 34" long to whatever number you more experienced folks would reccomend

2. Look for a 325gal tank and have a bigger smoker than I will ever need.

What should I do here?

Thanks, John