First and foremost no making fun of my lack of welding and fabrication skills. I built a vertical offset that I current use.

I wanted a smaller offset for smaller smokes and taking camping so I came across an expansion tank and started. Let me know if anything is too far off. CC is fairly thin and FB is little thicker than 16th but not quite an 1/8th. I know it light stuff but trying to keep it " loadable " in to truck. Any thoughts on build so far. It'll be week or so before I get back to it.

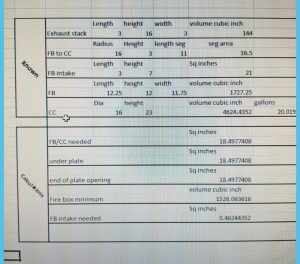

CC 16 diameter x 23 long. FB 11.75x12x12.25. Fresh air 3 x 7 with lid I can vary closed to open. Door 8 x 8.

Chimney 3x3x16

FB to CC 3x11

I wanted a smaller offset for smaller smokes and taking camping so I came across an expansion tank and started. Let me know if anything is too far off. CC is fairly thin and FB is little thicker than 16th but not quite an 1/8th. I know it light stuff but trying to keep it " loadable " in to truck. Any thoughts on build so far. It'll be week or so before I get back to it.

CC 16 diameter x 23 long. FB 11.75x12x12.25. Fresh air 3 x 7 with lid I can vary closed to open. Door 8 x 8.

Chimney 3x3x16

FB to CC 3x11