What I really like about this model is that it has remote.

I also have cold smoke attachment for it.

It looks like they do not make RF models anymore...

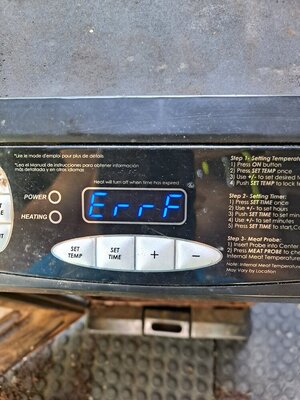

I wonder if I can just disable main sensor and use just a meat probe as one.

Do not know what PID is.

Can it work with remote control?

It is not possible to disable the main temp sensor and just use the meat probe as is.

It is theoretically possible to cut the wiring on the main sensor and splice in a meat probe sensor or another wall sensor to make it work BUT you have to know exactly what type of sensor they are using to begin with and hope it all works out. There are a few different types of sensors out there. This trial and error experiment would involve removing the back of your smoker and/or cutting a hole to get to the sensor and having about 3 different types of sensors on hand to play with, maybe more. I can only think of like 3 different types off the top of my head.

Think of it like changing out a part on a car like water pump or something. The "type" would be like a Nissan water pump, Ford water pump, GMC water pump, BMW water pump, etc. and you don't know what type of car you have so you have to try all the water pumps to figure out which one fits and works.

DougE

DougE

gave you a great explanation of a PID controller. As he said it just replaces the existing controller but only uses the box and heating element from the MES.

Auber makes a Wifi PID that allows you to do everything from your phone as long as your smoker is close enough to connect to your home wifi network.

Via this method you can access your smoker from anywhere anytime you want... as long as the PID is on and connected to the Wifi (may have to get a wifi extender to allow smoker to reach home wifi).

It runs a little bit more but everyone who gets it seems to love it, especially how much easier it is to deal with from the phone versus tweaking settings from the controller itself:

Auber Instruments, Inc. WIFI Electric Smoker Controller, 1800 Watts [AW-1520H] - 4th of July sale ends on 7/6/2025!This plug-and-play PID controller regulates the temperature of electric smokers, such as Smokin-it®, Smokin Tex, and

Masterbuilt Smoker. This controller uses a PID algorithm to...

www.auberins.com

Again, the cost of these controllers can make someone think "I can almost buy a new MES for that much". Which is not wrong BUT... when you put a controller like this on simply rewired MES, you are turning your golf cart of an MES into a Ferrari of a smoker that can do anything! So it really becomes apples to oranges to compare.