I have been wanting to build one of these for a while. I have started the process and should have it wrapped up this week. Here is what I have for now. I got the barrel burnt out today with some pallets. There was a liner of sorts in the barrel, it was red. After the fire, I scrubbed it down with an SOS pad and most of it came out. I will hit it with sand paper tomorrow and hopefully primer the outside.

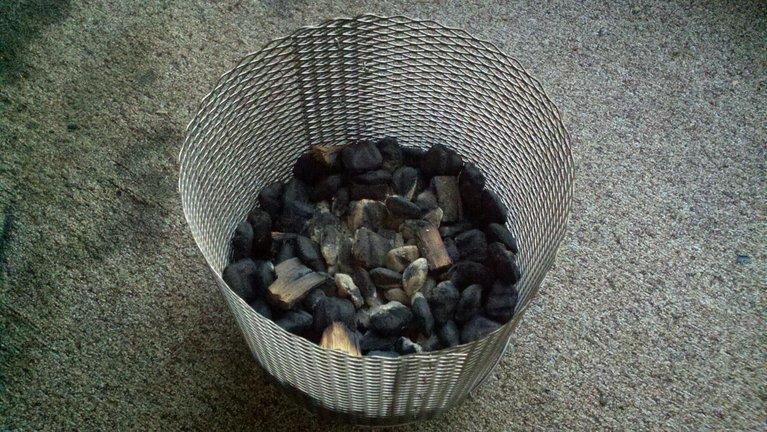

This is my new fire basket and grill grate.

https://statich.smokingmeatforums.com/3/37/37da6280_photobucket-4732-1332127823505.jpeg

https://statich.smokingmeatforums.com/8/8e/8ea2bb85_photobucket-3699-1331832141924.jpeg

https://statich.smokingmeatforums.com/6/64/647257fe_photobucket-5077-1332127853662.jpeg

https://statich.smokingmeatforums.com/c/cb/cb581fd7_photobucket-5439-1332127881609.jpeg

https://statich.smokingmeatforums.com/c/c3/c320d377_photobucket-6496-1332127902988.jpeg

https://statich.smokingmeatforums.com/8/88/88c58d66_photobucket-6769-1332127929915.jpeg

This is my new fire basket and grill grate.

https://statich.smokingmeatforums.com/3/37/37da6280_photobucket-4732-1332127823505.jpeg

https://statich.smokingmeatforums.com/8/8e/8ea2bb85_photobucket-3699-1331832141924.jpeg

https://statich.smokingmeatforums.com/6/64/647257fe_photobucket-5077-1332127853662.jpeg

https://statich.smokingmeatforums.com/c/cb/cb581fd7_photobucket-5439-1332127881609.jpeg

https://statich.smokingmeatforums.com/c/c3/c320d377_photobucket-6496-1332127902988.jpeg

https://statich.smokingmeatforums.com/8/88/88c58d66_photobucket-6769-1332127929915.jpeg

Last edited: