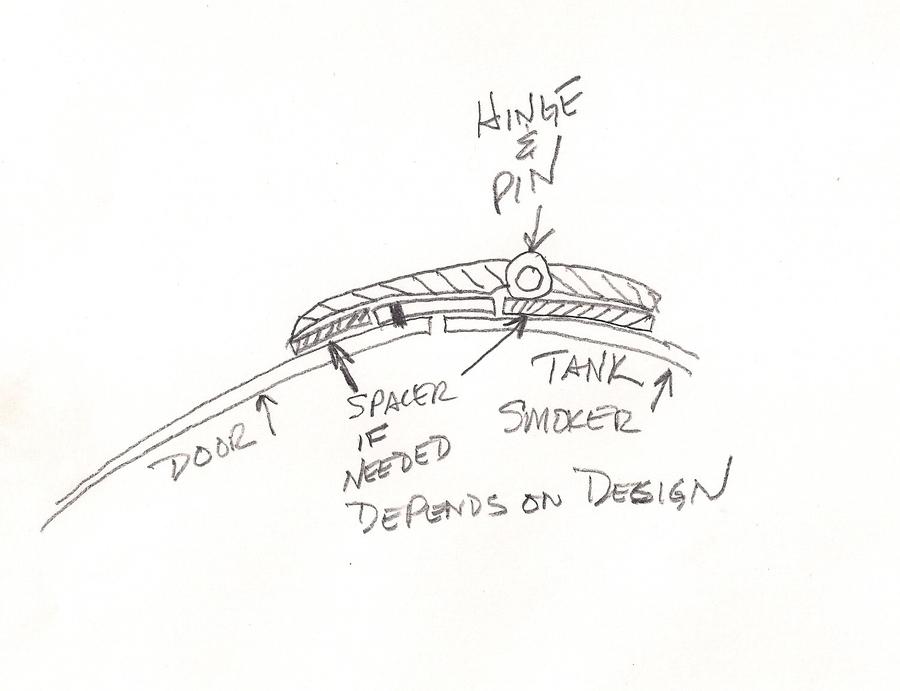

Ok, so I scrapped the idea of the 55 gal drum. I got the old air compressor from the back of the shop, rough cut the pump/motor and legs off of it. Its an 80 gal. tank that was built in (get this) 1957. I'm gonna leave the data plate on it cause nobody will believe me when its done. I've cut the door, put on some hinges and started the firebox. Per the calculator, the (slightly oversized} firebox is going to be 24" x 20" x 20" out of 3/8" diamond tread for the sides and top and bottom. 1/4" diamond tread for the back and door ( because that's the scrap I had). I am not sure of the placement of the firebox and RF plate. For example how far in and up does the fire box go on the end of the tank and what is the distance relationship between the RF plate and the firebox. Take a look at the pictures and tell me what y'all think.

Last edited: