Masterbuilt Vertical 2 door Smoker Mods

- Thread starter chadnicoletti

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Thats the front cloths line that we never use , except to feed the wood peckers suet, you can just see the 3 little cage holders. It was there when we bought the houseA fine example of advanced planning!

What is the pulley system?

But i should have said that is how "lovey" sends me my drinks when i run low

David

Hi Chadnicoletti for the likes and also for starting this thread , as it gave me the info i needed for the needle valve

David

David

- Dec 26, 2012

- 14

- 16

Hey DRKsmoking, I honestly can't take any credit for these mods, less the welded skirts. This forum is a wealth of information, and seriously awesome. I've been a tinkerer for a long time, and can't leave anything stock. Thankfully with a little elbow grease and some time, one can take a pretty poorly designed smoker for a great price and make a damn good smoker out of it! I have yet to try the tube deal that most on this forum speak of. I will get to that this summer.Hi Chadnicoletti for the likes and also for starting this thread , as it gave me the info i needed for the needle valve

David

Thanks!

The tube seems to be a good match for these smokers. I had difficulty using a pan. The harder woods like hickory had trouble staying lit at lower temps. I had trouble with a tray as well. Also check out an external smoke generator or mailbox. It really helps you get smoke and temperature consistency.

Hi OldSmoke, thanks for the likeThe tube seems to be a good match for these smokers. I had difficulty using a pan. The harder woods like hickory had trouble staying lit at lower temps. I had trouble with a tray as well. Also check out an external smoke generator or mailbox. It really helps you get smoke and temperature consistency.

Would you have a picture of your external smoke generator on your Masterbuilt. just so i can see . I do not seem to have a problem with my wood chunks staying lit ....so far but have only done a few smokes so fat, thanks

David

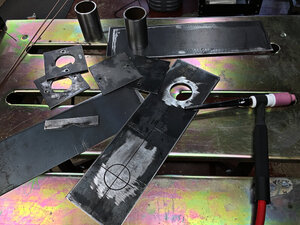

It is my own invention. It is what happens when it is cold and rainy outside and the garage is warm.

I use an air pump through a venturi to move the smoke. I can control the amount of smoke by adjusting the door and a valve on the compressed air. I’m getting consistent, clean smoke with zero temperature rise in the cabinet. I have two smoking tubes so it is easy and quick to reload on long smokes. It is one of those hair-brained ideas that actually works. I’m very happy with it.

I use an air pump through a venturi to move the smoke. I can control the amount of smoke by adjusting the door and a valve on the compressed air. I’m getting consistent, clean smoke with zero temperature rise in the cabinet. I have two smoking tubes so it is easy and quick to reload on long smokes. It is one of those hair-brained ideas that actually works. I’m very happy with it.

It is my own invention. It is what happens when it is cold and rainy outside and the garage is warm.

View attachment 486651

View attachment 486652

View attachment 486650

View attachment 486649

I use an air pump through a venturi to move the smoke. I can control the amount of smoke by adjusting the door and a valve on the compressed air. I’m getting consistent, clean smoke with zero temperature rise in the cabinet. I have two smoking tubes so it is easy and quick to reload on long smokes. It is one of those hair-brained ideas that actually works. I’m very happy with it.

WOW

that is very cool, fantastic work. And it does not raise the inside temp in the smoker?

That is one of the best mods to the Masterbuilt i have seen yet.

My hat is off to you sir. If it was made out of wood i could probably make it....LOL

David

Hi OldSmokeThese are the parts I used:

Missing is a 1/4 x 3/8 reducer that I sourced locally. You also need yellow, not white teflon tape (gas). If you have a good hardware store or propane supplier, they should have everything in stock. At the time in the pandemic, I was ordering everything online. The picture gives you some idea of how I plumbed it together.

View attachment 481857

The needle valve is not high pressure or low pressure. the output of the regulator and the type of burner you have is, and yours is low pressure.

When you put all your needle valve parts together do you use any tape at all. I was using the pink teflon tape to put the adapter on my 100lb tank and one of my neighbor said you dont need any tape or putty on any gas lines

am i wrong in doing so, thanks in advance

David

Last edited:

Hi OldSmoke

When you put all your needle valve parts together do you use any tape at all. I was using the pink teflon tape to put the adapter on my 100lb tank and one of my neighbor said you dont need any tape or putty on any gas lines

am i wrong in doing so, thanks in advance

David

Yes, with tapered pipe threads, you need a sealant. Yellow Teflon tape is used for natural gas and propane. If you are using flared fittings, you don’t use sealant.

Thank you. OldSmoke.Yes, with tapered pipe threads, you need a sealant. Yellow Teflon tape is used for natural gas and propane. If you are using flared fittings, you don’t use sealant.

David

After you have it assembled, spray some 409 or simple green on the joints to test for leaks. If you see any little bubbles, you have a leak.

After you have it assembled, spray some 409 or simple green on the joints to test for leaks. If you see any little bubbles, you have a leak.

Thank you, i normally always use soapy water spray on all my connections . did this for years in restaurants.After you have it assembled, spray some 409 or simple green on the joints to test for leaks. If you see any little bubbles, you have a leak.

When i first started in the restaurants i was showed to use a bic lighter to test the line and connections. I would love to meet that person that showed us that F**#ing fool.

And i was stupid enough to do what i was told. Many years ago, its a wonder i made it this far.

David

- Dec 26, 2012

- 14

- 16

Hey guys, I wanted to make an update. I know this is not specifically related to mods for our Masterbuilt smokers, but I think it's good info. I bought a smoke tube off of Amazon last week and gave it a try yesterday when I smoked a 4lb pork shoulder. Prior to using this tube I used an 8" cast iron which sat on the burner, with 2-3 large wood chunks for smoke. I used the stock water pan lined with aluminum foil full with water, meat placed on rack 2nd from the top, and smoker temp thermometer on same rack. I used this method for 2 years, and although it requires a ton of fiddling with needle valve and babysitting the smoker, i maintained temps from 215-235 for hours at a time. Yesterday I used the cast iron on the burner but with no chunks in it. I figured cast iron is very good for heat retention, and will allow consistent temps. I filled water pan and warmed her up to 225. Once at 225, I followed the instructions from the tube and filled it with pellets and lit vertically, and let burn for 10 minutes. I then placed it in the smoker as well as the meat. For the first 2.5 hours I had very consistent temp of 220-235, but at the 2.5 hr mark my water had completely boiled away. Instead of replacing it I mistakingly removed it based on thinking I'd be able to let er roll without having to add water every 2.5 hrs. Big mistake, lol. I had a hell of a time keeping the temp consistent, and from hour 4 on had to fiddle with it until 9.5 hrs when I took it off. This is all unrelated to the tube, which did perform well and lasted about 4 hrs . The key is to let it burn for the 10 minutes before laying it flat. I didn't do this the second fill, and it didn't smoke well. So, I am a believer in the tube, but would like to know the setups of you guys who use the tube with these smokers. Are you guys using cast iron still for radiant heat? I know I messed up removing water pan, but what other things are you doing to achieve consistent temp?

Thanks!

Thanks!

Which tube did you buy off Amazon, that works for you in our smokers, the link in your post is just to amazonHey guys, I wanted to make an update. I know this is not specifically related to mods for our Masterbuilt smokers, but I think it's good info. I bought a smoke tube off of Amazon last week and gave it a try yesterday when I smoked a 4lb pork shoulder. Prior to using this tube I used an 8" cast iron which sat on the burner, with 2-3 large wood chunks for smoke. I used the stock water pan lined with aluminum foil full with water, meat placed on rack 2nd from the top, and smoker temp thermometer on same rack. I used this method for 2 years, and although it requires a ton of fiddling with needle valve and babysitting the smoker, i maintained temps from 215-235 for hours at a time. Yesterday I used the cast iron on the burner but with no chunks in it. I figured cast iron is very good for heat retention, and will allow consistent temps. I filled water pan and warmed her up to 225. Once at 225, I followed the instructions from the tube and filled it with pellets and lit vertically, and let burn for 10 minutes. I then placed it in the smoker as well as the meat. For the first 2.5 hours I had very consistent temp of 220-235, but at the 2.5 hr mark my water had completely boiled away. Instead of replacing it I mistakingly removed it based on thinking I'd be able to let er roll without having to add water every 2.5 hrs. Big mistake, lol. I had a hell of a time keeping the temp consistent, and from hour 4 on had to fiddle with it until 9.5 hrs when I took it off. This is all unrelated to the tube, which did perform well and lasted about 4 hrs . The key is to let it burn for the 10 minutes before laying it flat. I didn't do this the second fill, and it didn't smoke well. So, I am a believer in the tube, but would like to know the setups of you guys who use the tube with these smokers. Are you guys using cast iron still for radiant heat? I know I messed up removing water pan, but what other things are you doing to achieve consistent temp?

Thanks!

thanks

David

- Dec 26, 2012

- 14

- 16

Smoke Tube I bought

I have the same tube and it works well. The best thing you can do is a mailbox setup. The tube generates over 20 degrees of heat that is variable and cannot be controlled. Put it outside of the cabinet and you will get better temperature consistency, and better smoke.

When i first started in the restaurants i was showed to use a bic lighter to test the line and connections. I would love to meet that person that showed us that F**#ing fool.

Oh my. After 35 years in the natural gas distribution industry, I can personally verify, this is not the best way to find a leak. Well, you will find the leak, but...

- Dec 26, 2012

- 14

- 16

I have the same tube and it works well. The best thing you can do is a mailbox setup. The tube generates over 20 degrees of heat that is variable and cannot be controlled. Put it outside of the cabinet and you will get better consistency, and better smoke.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 6

- Views

- 6K

- Replies

- 15

- Views

- 2K

- Replies

- 7

- Views

- 862

- Replies

- 9

- Views

- 8K

Hot Threads

-

Featured It’s the Season!

- Started by civilsmoker

- Replies: 32

- General Discussion

-

Dehydrater

- Started by pc farmer

- Replies: 31

- Blowing Smoke Around the Smoker.

-

Prime Rib Sale

- Started by Gonna Smoke

- Replies: 22

- Beef

-

Bathroom Update

- Started by Chris_in_SoCal

- Replies: 15

- General Discussion

-

Featured 6 racks of St. Louis ribs

- Started by motolife313-2

- Replies: 14

- Pork