Hello fellows,

I am new on the forum however I would like to ask you help to solve several problems I am having to keep the temperature of my smoker steady after made the mods for a horizontal smoker. I will appreciate any help you can provide me.

First let me provide you some information about the smoke. The smoker is an Omaha offset smoker, it is pretty similar to the Brinkmann offset smoker, here there are some pictures of it.

Now, as you already know, this kind of smoker needs a set of modification in order they work as they should work. So, after research on the web, I proceed to make the following modification base on this website, http://amazingribs.com/tips_and_technique/offset_smokers.html/ .

These are the results after I applied the mods:

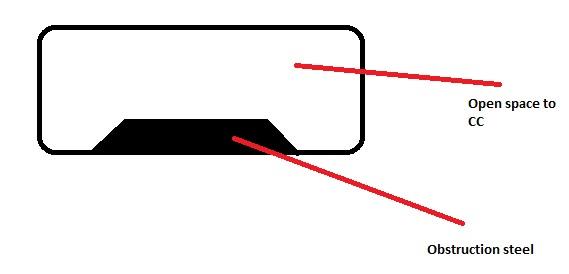

1. Reverse flow system: As you can see on the picture, I installed a heavy steel duct like the ones built into the large commercial offset smokers and moved the chimney to the side by the firebox. However, I am not sure if I am using the right width for the heavy steel duct, I am feeling the steel is very width therefore it is very difficult to warm it with the heat that is coming from the firebox. Please note that I also have added a deflector as part of the modification.

This is the deflector that I installed on the cooking chamber.

This the heavy steel duct.

And this is the final set up with the deflector and steel duct together.

2. Make a charcoal basket and add a bottom grate to the firebox. On this modification, I am not sure what is the best position to sit the charcoals on the basket? Right now, when I place the charcoals on the basket, the charcoal just sat 5 inches below to the cooking chamber's duct. I am guessing this could affect the amount of heat that cooking chamber is receiving from firebox.

Please take a look of the following pictures and explanations

This is the charcoal basket on the firebox.

Please note that charcols are sitteing 5" above the opening cooking chamber conduct.

Please note the charcoals are not sat on the botton of the firebox, there is an space betweeen the botton onf the firebox and the charcoals

3. Extend the chimney downward and add thermometers: These mods are working as expected.

Finally, this are my questions and problems

1. After put a lot briquets on the charcoal basket, temperature does not increase more than 150 F.

2. The charcols turn off after around 60 min. I am feeling this is because there is not enougth oxigen on the firebox or the vent are not big enought to feed the charcoals. Please take a look of the vent coming with the smoker

Finally, I would like to thanks in advance for any help you can provideme to fix this smoker..

I am new on the forum however I would like to ask you help to solve several problems I am having to keep the temperature of my smoker steady after made the mods for a horizontal smoker. I will appreciate any help you can provide me.

First let me provide you some information about the smoke. The smoker is an Omaha offset smoker, it is pretty similar to the Brinkmann offset smoker, here there are some pictures of it.

Now, as you already know, this kind of smoker needs a set of modification in order they work as they should work. So, after research on the web, I proceed to make the following modification base on this website, http://amazingribs.com/tips_and_technique/offset_smokers.html/ .

These are the results after I applied the mods:

1. Reverse flow system: As you can see on the picture, I installed a heavy steel duct like the ones built into the large commercial offset smokers and moved the chimney to the side by the firebox. However, I am not sure if I am using the right width for the heavy steel duct, I am feeling the steel is very width therefore it is very difficult to warm it with the heat that is coming from the firebox. Please note that I also have added a deflector as part of the modification.

This is the deflector that I installed on the cooking chamber.

This the heavy steel duct.

And this is the final set up with the deflector and steel duct together.

2. Make a charcoal basket and add a bottom grate to the firebox. On this modification, I am not sure what is the best position to sit the charcoals on the basket? Right now, when I place the charcoals on the basket, the charcoal just sat 5 inches below to the cooking chamber's duct. I am guessing this could affect the amount of heat that cooking chamber is receiving from firebox.

Please take a look of the following pictures and explanations

This is the charcoal basket on the firebox.

Please note that charcols are sitteing 5" above the opening cooking chamber conduct.

Please note the charcoals are not sat on the botton of the firebox, there is an space betweeen the botton onf the firebox and the charcoals

3. Extend the chimney downward and add thermometers: These mods are working as expected.

Finally, this are my questions and problems

1. After put a lot briquets on the charcoal basket, temperature does not increase more than 150 F.

2. The charcols turn off after around 60 min. I am feeling this is because there is not enougth oxigen on the firebox or the vent are not big enought to feed the charcoals. Please take a look of the vent coming with the smoker

Finally, I would like to thanks in advance for any help you can provideme to fix this smoker..

Last edited: