I have been reading and reading on RF and all the builds here and dreaming. This may sound funny but I was watching Gold Rush the other day and they were talking about a sluice box and how it works to remove the gold. I thought if you turned the box up side down and turned it around the technology of it would work in reverse for a reverse flow plate. So by starting at the fire box side if you had strips or fins of steel welded down under the plate then the heat should create a cyclone effect in front of each fin. Instead of the gold dropping into the box this way the heat would rise and get trapped I would think that if you started with 1/8x1/2 for the first couple rows the heat would travel fast then go to 1/8x3/4 for a few more rows then 1/8x1 there the heat would be moving slower because of more surface area then keep going lower with each few rows to the end.

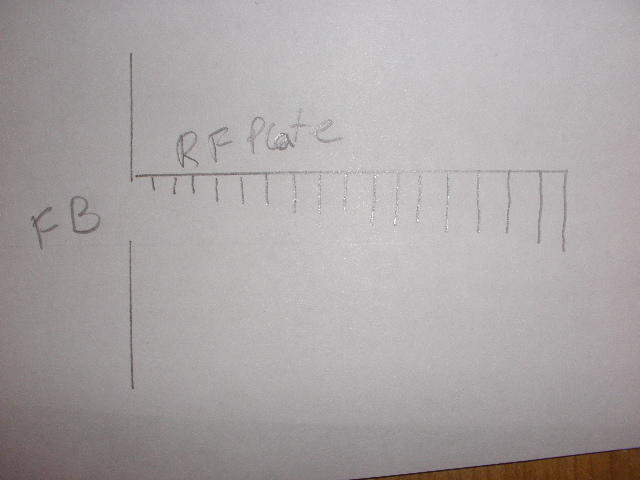

Picture just to get a idea of what I mean. picture not to scale

I am not an expert or even close but when the show explained the sluice box technology I thought it would be worth thinking about. I don’t know how far apart they should be so as to get the most cyclone action but I might try this.

. What do you guys think?

Picture just to get a idea of what I mean. picture not to scale

I am not an expert or even close but when the show explained the sluice box technology I thought it would be worth thinking about. I don’t know how far apart they should be so as to get the most cyclone action but I might try this.

. What do you guys think?