Hey guys,

I am starting my first "big" smoker project, and of course big is relative. I have built two 55 gallon double barrel smokers in the past (one this May and one a few weeks ago), but I decided to step into the big leagues and make a trailer smoker.

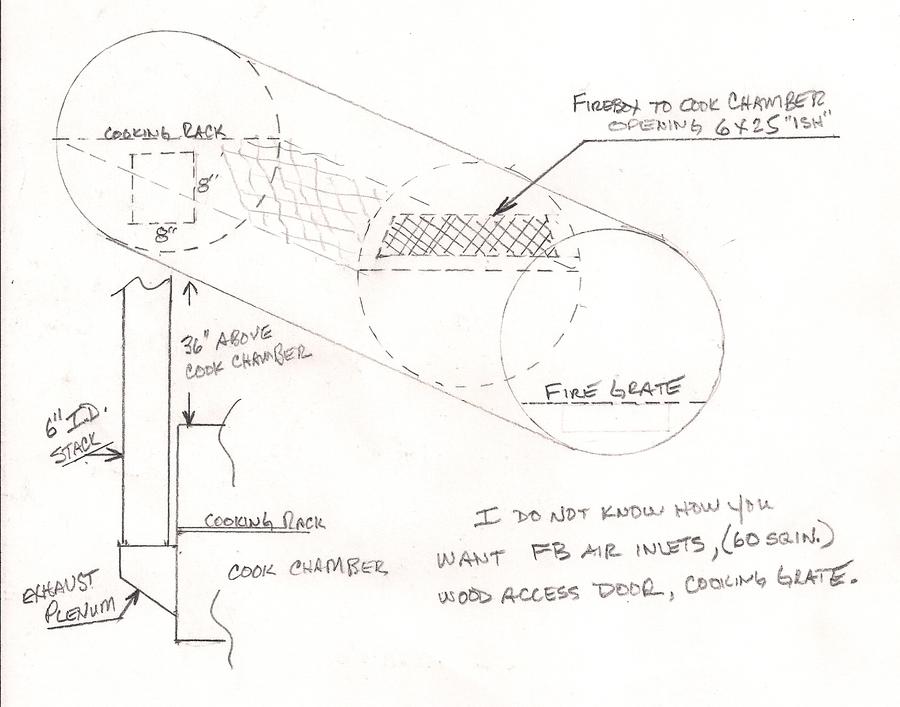

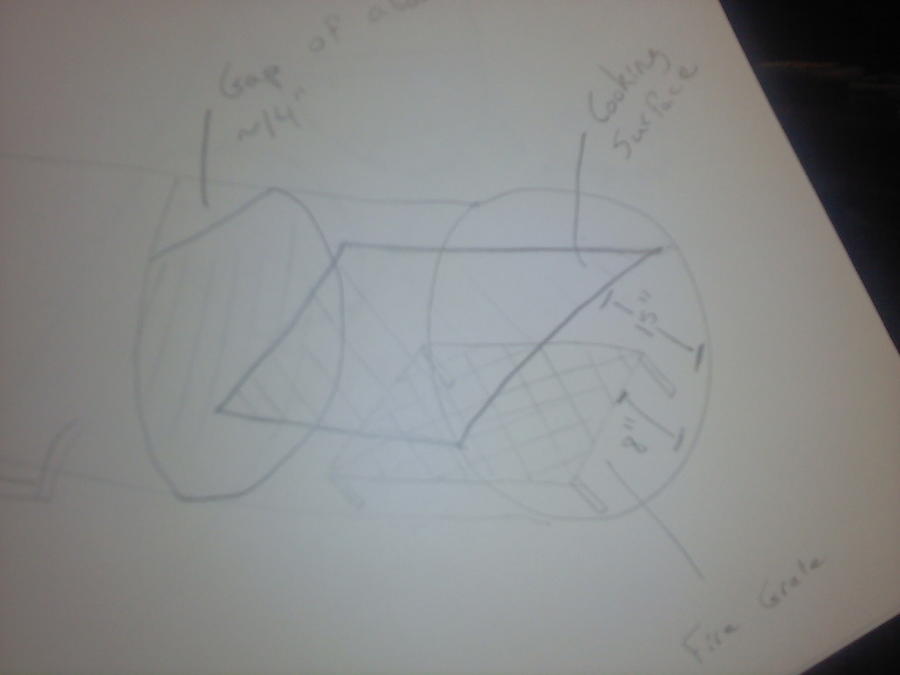

The smoker I am making is a tank that is 7 feet long and has a 30 inch diameter. I was originally going to make a typical smoker with a separated fire box piped into the tank, but today plans changed a little. As I was pulling out my 5 foot fire box to cut down to size, it was obvious that it would be big and gauty. So my biggest critic (my dad) suggested that I make 1/3 of the tank the fire box and make the other 2/3 of the tank the smoker since more than likely I will not need 7 feet of smoking room any way. BUT the twist is that the fire area will have a rack in it to turn it into a direct heat/open flame grill. This will give the rig the versatility of wood fire grilling steaks, burgers, and hot dogs while at the same time being able to slow cook boston butts, ribs, chickens, and turkeys on the other side.

The inside of the tank will have a steel plate dividing the fire area from the smoker area so true smoking can be done on the larger portion.

The question is, what is this setup called? I'm sure I am not the first person to build this type of cooker.

Also, has anyone ever used a down draft style smoker? Where the smoke and heat enter the tank high and the exhaust is below the cook racks. This is the setup I will have to use due to the fire "box" and the smoker tank being the same thing and on the same level.

Another question I have is, has anyone ever used wire pallet racks for meat racks? They are the wire part that sits on the metal frame that is used to store pallets of goods in ware houses. They are rated at 2000+ lbs. and they sell on ebay for $14 for a 36X48 inch rack. My only concern is on the "grill/firebox" side hotdogs and burgers may fall through when being flipped.

Another option I thought of is wire racks sold by Uline and Global industrial. They come in a variety of sizes but cost anywhere from $26-$50 a piece. Their weight capacity is 800 lbs and they come in a chrome finish.

Any tips and advice is much welcomed.

Here is the start of this project. I started this Saturday.

I am going to deck in the back part of the trailer and put removable walls to carry wood with me. I am also going to build a table over about half of this area. The table will be high enough to store wood under but not so high that it would be uncomfortable to prepare food on. The angle iron I welded in this area is to bolt the decking onto in the future. Plus it stiffens the trailer up a little.

I am starting my first "big" smoker project, and of course big is relative. I have built two 55 gallon double barrel smokers in the past (one this May and one a few weeks ago), but I decided to step into the big leagues and make a trailer smoker.

The smoker I am making is a tank that is 7 feet long and has a 30 inch diameter. I was originally going to make a typical smoker with a separated fire box piped into the tank, but today plans changed a little. As I was pulling out my 5 foot fire box to cut down to size, it was obvious that it would be big and gauty. So my biggest critic (my dad) suggested that I make 1/3 of the tank the fire box and make the other 2/3 of the tank the smoker since more than likely I will not need 7 feet of smoking room any way. BUT the twist is that the fire area will have a rack in it to turn it into a direct heat/open flame grill. This will give the rig the versatility of wood fire grilling steaks, burgers, and hot dogs while at the same time being able to slow cook boston butts, ribs, chickens, and turkeys on the other side.

The inside of the tank will have a steel plate dividing the fire area from the smoker area so true smoking can be done on the larger portion.

The question is, what is this setup called? I'm sure I am not the first person to build this type of cooker.

Also, has anyone ever used a down draft style smoker? Where the smoke and heat enter the tank high and the exhaust is below the cook racks. This is the setup I will have to use due to the fire "box" and the smoker tank being the same thing and on the same level.

Another question I have is, has anyone ever used wire pallet racks for meat racks? They are the wire part that sits on the metal frame that is used to store pallets of goods in ware houses. They are rated at 2000+ lbs. and they sell on ebay for $14 for a 36X48 inch rack. My only concern is on the "grill/firebox" side hotdogs and burgers may fall through when being flipped.

Another option I thought of is wire racks sold by Uline and Global industrial. They come in a variety of sizes but cost anywhere from $26-$50 a piece. Their weight capacity is 800 lbs and they come in a chrome finish.

Any tips and advice is much welcomed.

Here is the start of this project. I started this Saturday.

I am going to deck in the back part of the trailer and put removable walls to carry wood with me. I am also going to build a table over about half of this area. The table will be high enough to store wood under but not so high that it would be uncomfortable to prepare food on. The angle iron I welded in this area is to bolt the decking onto in the future. Plus it stiffens the trailer up a little.

Last edited: