In a fit of Oregon rain-induced insanity, I decided to add a convection fan to my Masterbuilt propane cabinet smoker. My two goals were to; even out the temps in the cabinet, and to circulate the smoke more evenly. I was routinely measuring 30+ degree temp differences between the racks. Additionally, the smoke tends to enter the cabinet, run up the back wall, and exit the rear vent, without circulating amongst the racks. My solution was to add a fan. Whoohoo!

This is the finished project mounted on the rear of the cabinet. The screened vent holes help cool the motor. Due to the design of the fan blade, it is best to mount the fan in the center of the largest surface as possible. This usually means the rear of the cabinet. The sides are a possibility, but the rack rails might be a problem. You just have to stare at it a bit to decide the best spot for your particular cabinet design.

This is the fan purchased from eBay. Most of the fans for all of the appliance brands seem to look alike. This one came with a soft rubber seal for the shaft to keep the smoke from leaking out. If you look closely, you can see a small fan blade next to the motor to keep it cool. This is desirable. Additionally, this motor has three terminals to connect to, high and low speeds. This is also desirable. With the addition of a simple switch, you can control the speed. My theory is, you want to run fast enough to even out the temps, but not so fast as to tumble-dry the meat.

When you look at the large fan, you will notice it is not a typical propeller. It does not blow air at you. Instead, it is more like a paddle wheel, blowing air out to the sides. I suspect this causes the air to circulate around in the cabinet, bouncing off the walls, rather than blowing straight across the meat causing it to dry out. Smart engineers.

If you buy a used fan, make sure you get the fan and the nut. The nut may use left-handed threads and can be expensive unless you have a very good hardware store nearby.

I used a metal junction box without knockouts. I painted it with Rustoleum Textured Black. This paint is a pretty good match for these cabinets. I cut vents in the sides with screens for cooling. A step drill works great for this. If you are using an uninsulated propane smoker, I recommend not to mount it flush to the surface of the smoker cabinet. Space it out with a couple of washers under each mounting bolt. Mounting it flush will cause it to get very hot. This will make your motor very unhappy.

I went crazy and added a speed control from Amazon. I gutted the electronics out of this heat sink. In retrospect, a two-speed toggle switch would be just as good. Although the knob is fun to twiddle with and it looks sexy.

Here it is all packaged up. The motor may have a long shaft. Mine does, so I made some stand-offs out of small diameter tubing for the mounting bolts to pass through, raising the fan mount off the surface of the metal junction box. The fan should be as close to the surface of the interior cabinet wall as the mounting bolts will allow. If the bolts are too long, protruding above the nut, the fan may contact them. Clink, tink, clink. It can be very musical. Don’t ask me how I know this.

Before you start drilling your mounting and shaft holes, realize the fan will take up space where you might want to position your racks. With a little head-scratching, you will find a spot. Position it as close to the middle as possible. If you have a divided cabinet, the fan should be in the cooking section rather than the heating section. My installation required the power wire to travel inside the cabinet to a panel mounted switch. I used special high-temp oven wire. In most cases, you should be able to run a power cord straight out of the junction box. If you do this, add a strain relief to the cord and route it though a rubber grommet. One suggestion is to think about powering the fan on its own, separate from any other temp controls so you can cold smoke without a burner or heating element running.

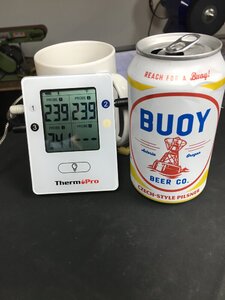

As you can see, I am now getting consistent temps across the racks. The beer was much colder and wasn’t included in the measurements. My test smoke of cheese had the best, most even smoke coverage I have ever gotten. All of the bricks look the same and are the best tasting yet. I think this is going to be the cat’s-meow for jerky where you need airflow to dry the strips of meat.

Here it is, chugging away! I will include the parts information in the next post.

This is the finished project mounted on the rear of the cabinet. The screened vent holes help cool the motor. Due to the design of the fan blade, it is best to mount the fan in the center of the largest surface as possible. This usually means the rear of the cabinet. The sides are a possibility, but the rack rails might be a problem. You just have to stare at it a bit to decide the best spot for your particular cabinet design.

This is the fan purchased from eBay. Most of the fans for all of the appliance brands seem to look alike. This one came with a soft rubber seal for the shaft to keep the smoke from leaking out. If you look closely, you can see a small fan blade next to the motor to keep it cool. This is desirable. Additionally, this motor has three terminals to connect to, high and low speeds. This is also desirable. With the addition of a simple switch, you can control the speed. My theory is, you want to run fast enough to even out the temps, but not so fast as to tumble-dry the meat.

When you look at the large fan, you will notice it is not a typical propeller. It does not blow air at you. Instead, it is more like a paddle wheel, blowing air out to the sides. I suspect this causes the air to circulate around in the cabinet, bouncing off the walls, rather than blowing straight across the meat causing it to dry out. Smart engineers.

If you buy a used fan, make sure you get the fan and the nut. The nut may use left-handed threads and can be expensive unless you have a very good hardware store nearby.

I used a metal junction box without knockouts. I painted it with Rustoleum Textured Black. This paint is a pretty good match for these cabinets. I cut vents in the sides with screens for cooling. A step drill works great for this. If you are using an uninsulated propane smoker, I recommend not to mount it flush to the surface of the smoker cabinet. Space it out with a couple of washers under each mounting bolt. Mounting it flush will cause it to get very hot. This will make your motor very unhappy.

I went crazy and added a speed control from Amazon. I gutted the electronics out of this heat sink. In retrospect, a two-speed toggle switch would be just as good. Although the knob is fun to twiddle with and it looks sexy.

Here it is all packaged up. The motor may have a long shaft. Mine does, so I made some stand-offs out of small diameter tubing for the mounting bolts to pass through, raising the fan mount off the surface of the metal junction box. The fan should be as close to the surface of the interior cabinet wall as the mounting bolts will allow. If the bolts are too long, protruding above the nut, the fan may contact them. Clink, tink, clink. It can be very musical. Don’t ask me how I know this.

Before you start drilling your mounting and shaft holes, realize the fan will take up space where you might want to position your racks. With a little head-scratching, you will find a spot. Position it as close to the middle as possible. If you have a divided cabinet, the fan should be in the cooking section rather than the heating section. My installation required the power wire to travel inside the cabinet to a panel mounted switch. I used special high-temp oven wire. In most cases, you should be able to run a power cord straight out of the junction box. If you do this, add a strain relief to the cord and route it though a rubber grommet. One suggestion is to think about powering the fan on its own, separate from any other temp controls so you can cold smoke without a burner or heating element running.

As you can see, I am now getting consistent temps across the racks. The beer was much colder and wasn’t included in the measurements. My test smoke of cheese had the best, most even smoke coverage I have ever gotten. All of the bricks look the same and are the best tasting yet. I think this is going to be the cat’s-meow for jerky where you need airflow to dry the strips of meat.

Here it is, chugging away! I will include the parts information in the next post.

Last edited: