Been working the past couple days on the smoker, I feel like I got quite a bit done. I have learned a couple things, 1. metal work takes a lot longer than I thought. 2. Metal Is not wood (Duh right!) I just mean the way metal acts and reacts is crazy and confusing, and frustrating. 3. Welding is an actually pretty fun, although I am no doubt horrible at it, it is fun and I will get better with time. 4. Building this smoker is awesome, and seeing progress makes me want to keep going!

Anyway, here are some photos!

Dave I did as you had said, welded them according to the pattern. I don't know if I didn't do something right because only a couple stuck, I ended up having to tack it.

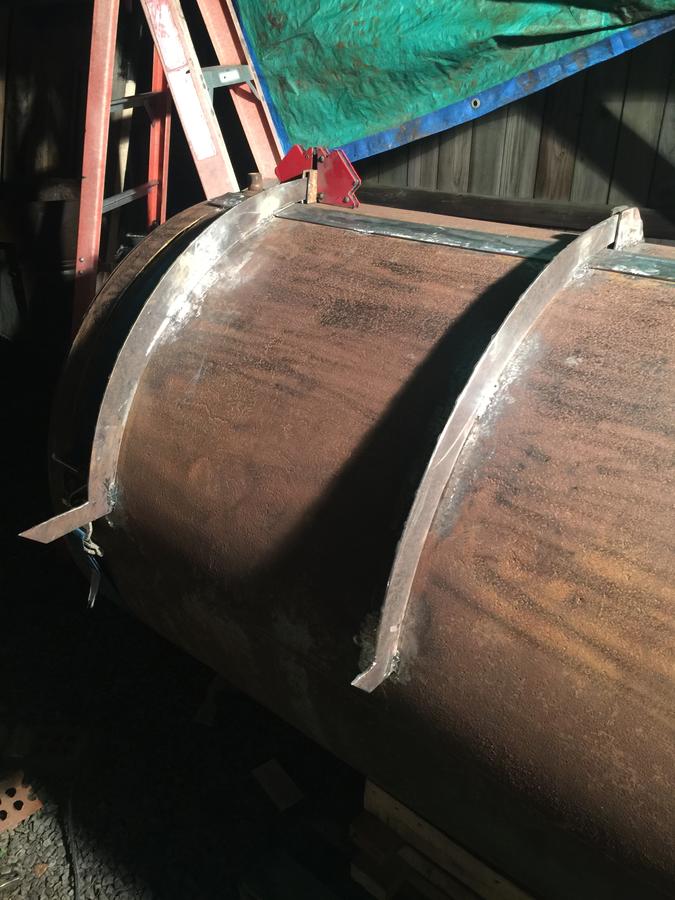

Fabricated these ribs to help prevent the door from springing and twisting but they didn't really do what I was hoping.

This is my first time ever welding anything, They don't look the best but they are holding!!

So here is my problem, my ribs didn't keep the door how I was hoping, the door has done this on all 4 corners and I am not real sure what to do about it, how can I fix it?

This is where we are at right now, door cut, ribs and door trim cut and welded, Hinges in place and functioning.Its starting to look like a smoker!!! probably will do a quick burnout tomorrow then work on the Door handle, RF plate supports, cut the fire box opening, and work on the stack, does anyone have a recommendation on how for into the CC the stack should go? Feldons call for 40" is that all together? or is that 40" sticking out? The stack will be directly in the middle of the CC. considering this is going to be a center feed.