- Feb 28, 2016

- 48

- 35

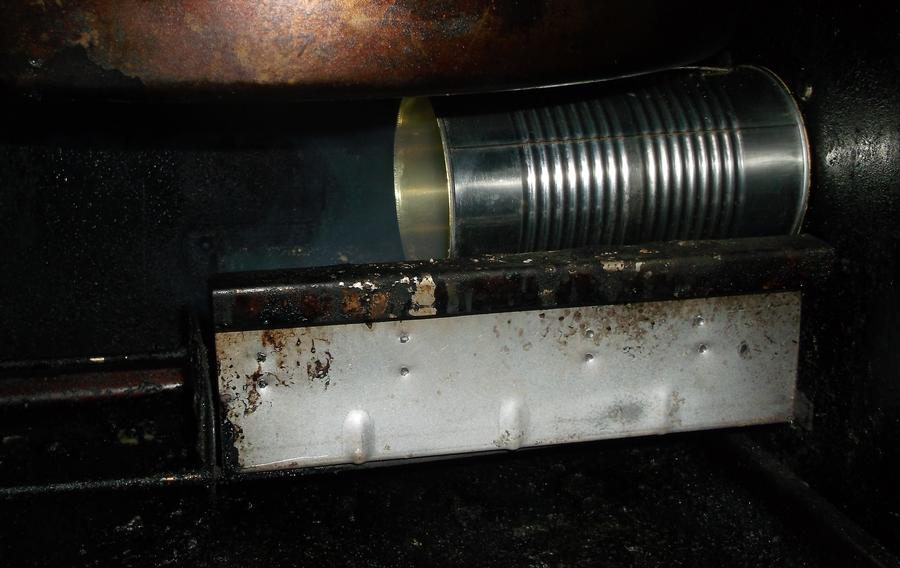

OK, thanks! That is how I was going to set it up, but the pipe stuck out so far on each side that it was a non starter. The stand I made is 23" wide, and the pipe+connections hung out a foot on each side in a horizontal configuration, so it wouldn't work for where this smoker needs to sit. If condensation is the only reason to have it horizontal then I'm not sure that it will be a problem. I plan on cutting the last section of pipe down so that the flow from it to the smoker is on an incline. It will probably be around 24'' long instead of 36" to accomplish this. If condensate did form in this system, and was allowed to pool in the lower bends in the pipe, why would that be bad? The fans I am using to pull smoke through the system draw very little amperage. I could leave them running for 24 hours after I'm done smoking in order to dry condensate out of the system and it would only cost me a nickle. I don't understand where the condensate would be coming from as this loop is before the cooking chamber. There is little to no water vapor coming from the pellets/dust in the smoke generator, and the airflow of the system will take care of that by itself. What am I missing?

You have the right idea of which I was referring too although the positioning is 90° off. The pipe should be laying horizontally with a slight incline so the condensation can flow away from the smoker and toward the generator. Will send pic of another's setup whom I am working with.

Tom

Last edited: