Thanks, I will go with a spark starter. I've checked out kits at Lowes. The past week I've been doing a few things, but I can't download pics off phone

for some reason. First I made a couple chimney stacks so I can vent off from the bottom cooking grates, made rectangular so I can run them interior

and not looses a whole lot of cooking space. I refered to a ductulator for proper sizing of 5 inch round, come up with 3 by 8..........

I'll run stacks up to top of cook chambers and tap off those with the 5inch round I already fabricated.

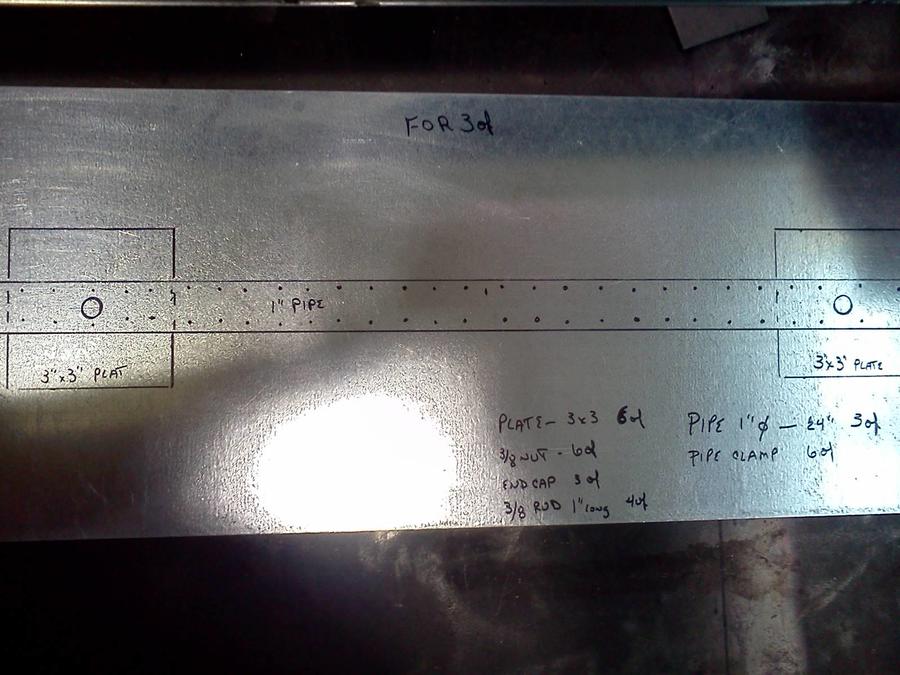

Also I've also gathered and fabbed stock for a damper system for the air intakes on the Fire Box. I had a friend cut and groove 3 1/2 inch round solid rod

into 1/4 inch pucks, these will fit over the pipes on bottom to adjust intake. Then I cut some lengths of 1/4 inch rod and some pieces of pipe to receive

rod and allow rod to spin. I'll tack pucks to rod, weld pipe pieces in location to allow rod to spin and act for dampening......... I'll dill and tap pipe and use a wing

top bolt to lock in place. Sorry for blind description, can't download pics and just wanted to keep going.