- Jun 9, 2014

- 17

- 13

I've read a few of the propane builds here and this is "my plan"....

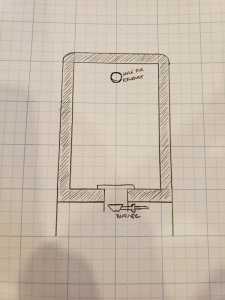

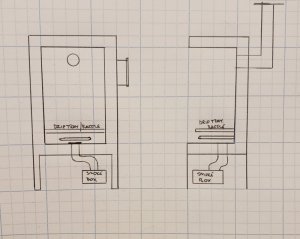

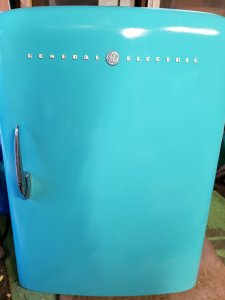

I have this old (50's maybe) GE fridge and the base to a propane turkey deep frying kit, so my thoughts are to cut a hole in the bottom of the fridge so the propane set-up is as low as possible leaving more room for drip tray/heat baffle and shelves. I'll put chunks/chips into a cast iron or steel pan on top of the burner for smoke. I also plan to run all plumbing and wiring in the bottom portion of the fridge where the condensing unit used to sit. See sketch.

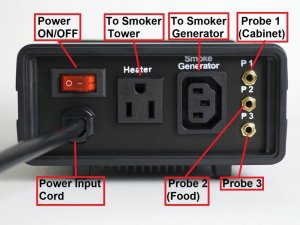

I also plan to run a needle valve/solenoid set-up similar to what is shown in this thread to control internal temps. And yes, I will be running a safety shut off valve.

https://www.smokingmeatforums.com/threads/digital-temp-mod.232758/

So far I have completely disassembled the unit and removed all the old insulation. I have seen varying opinions on whether or not to do this but for the minimal cost to put in the mineral wool I figured it was just as easy to change it now. Also as I was taking it apart I notice the bottom of the shell was rusted out any the insulation in that area needed to be removed regardless to make the repairs so it only made sense to remove it all.

So here are my list of questions at this point...

1. Can I use the leftover piece of enameled door skin to cut out parts for the replacement plastic pieces? I have no idea if cutting drilling enameled metal is good/bad/indifferent.

2. How do you guys recommend filling all the various holes in the enameled fridge liner?

3. The way I plan to set the propane burner into the bottom of the pan, the underside of the burner will be open to the air and I did not intend to restrict air flow into the smoker. My thoughts are if I baffle/damper/control the amount of exhaust from the smoke chamber I should not have to regulate the air intake. Is this a valid idea or should I reconsider this to limit the amount of air going into the unit and not the exhaust.

4. What type of sealant do you guys recommend for use inside the smoker?

Any and all help/suggestions are greatly appreciated.

I have this old (50's maybe) GE fridge and the base to a propane turkey deep frying kit, so my thoughts are to cut a hole in the bottom of the fridge so the propane set-up is as low as possible leaving more room for drip tray/heat baffle and shelves. I'll put chunks/chips into a cast iron or steel pan on top of the burner for smoke. I also plan to run all plumbing and wiring in the bottom portion of the fridge where the condensing unit used to sit. See sketch.

I also plan to run a needle valve/solenoid set-up similar to what is shown in this thread to control internal temps. And yes, I will be running a safety shut off valve.

https://www.smokingmeatforums.com/threads/digital-temp-mod.232758/

So far I have completely disassembled the unit and removed all the old insulation. I have seen varying opinions on whether or not to do this but for the minimal cost to put in the mineral wool I figured it was just as easy to change it now. Also as I was taking it apart I notice the bottom of the shell was rusted out any the insulation in that area needed to be removed regardless to make the repairs so it only made sense to remove it all.

So here are my list of questions at this point...

1. Can I use the leftover piece of enameled door skin to cut out parts for the replacement plastic pieces? I have no idea if cutting drilling enameled metal is good/bad/indifferent.

2. How do you guys recommend filling all the various holes in the enameled fridge liner?

3. The way I plan to set the propane burner into the bottom of the pan, the underside of the burner will be open to the air and I did not intend to restrict air flow into the smoker. My thoughts are if I baffle/damper/control the amount of exhaust from the smoke chamber I should not have to regulate the air intake. Is this a valid idea or should I reconsider this to limit the amount of air going into the unit and not the exhaust.

4. What type of sealant do you guys recommend for use inside the smoker?

Any and all help/suggestions are greatly appreciated.