- Jul 17, 2018

- 22

- 1

And so it starts. The minute I removed this old stainless pool filter I knew there would be a purpose for it. The original intention was to make a kettle BBQ which has now morphed into a smoker. I recently acquired another of almost identical diameter (to the mm) and my options increased.

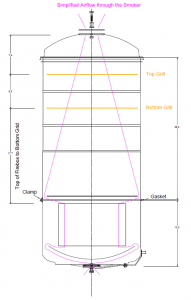

So the two drums left and right represent one filter on the middle and front the original filter. The internal diameter is near as dammit to 18”. The entire build will be stainless steel, and as far as possible I will be using the features of the drums to reduce the amount of work. For example my air inlet will be through the 2” hole in the base “A” providing for what I believe will be superior air flow.

This hole will have an adjustable diffuser to manage the inflow of air. The interior of the filters is perfect.

So the top of “B” get removed as well as the bottom of “C” which will then be repurposed as an ash tray for the firebox. “C” will then be placed on top of “B” and welded in situ.

So the top of “B” get removed as well as the bottom of “C” which will then be repurposed as an ash tray for the firebox. “C” will then be placed on top of “B” and welded in situ.

That assembly then get place on “A” once inverted. That is the natural position for that filter “B” on “A”. The two are held together with a round clamp and a 5/8” Viton rubber seal will provide the ar tightness. The reason for not welding is to make it a transportable in an SUV. May stlll weld them together, time will tell.

The pipes on “C” will be removed and the holes patched and welded. There is an O Ring retaining lip on the top of “C” into which a 5/8” Viton seal will be placed to allow the lid to seal. A hinge will follow in time as will access point for temperature probes etc.

So progress at last. The outside has not cleaned up as well as I anticipated so I am strongly considering powder coating the exterior.

So far the cost $ 0.00. My buddy did the welding and is making the Stainless Vents for me.

The standard 57cm Weber Kettle grids fit perfectly.

More pics to follow as we progress.

So the two drums left and right represent one filter on the middle and front the original filter. The internal diameter is near as dammit to 18”. The entire build will be stainless steel, and as far as possible I will be using the features of the drums to reduce the amount of work. For example my air inlet will be through the 2” hole in the base “A” providing for what I believe will be superior air flow.

This hole will have an adjustable diffuser to manage the inflow of air. The interior of the filters is perfect.

That assembly then get place on “A” once inverted. That is the natural position for that filter “B” on “A”. The two are held together with a round clamp and a 5/8” Viton rubber seal will provide the ar tightness. The reason for not welding is to make it a transportable in an SUV. May stlll weld them together, time will tell.

The pipes on “C” will be removed and the holes patched and welded. There is an O Ring retaining lip on the top of “C” into which a 5/8” Viton seal will be placed to allow the lid to seal. A hinge will follow in time as will access point for temperature probes etc.

So progress at last. The outside has not cleaned up as well as I anticipated so I am strongly considering powder coating the exterior.

So far the cost $ 0.00. My buddy did the welding and is making the Stainless Vents for me.

The standard 57cm Weber Kettle grids fit perfectly.

More pics to follow as we progress.